Are you a seasoned Sheet Metal Journeyman seeking a new career path? Discover our professionally built Sheet Metal Journeyman Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

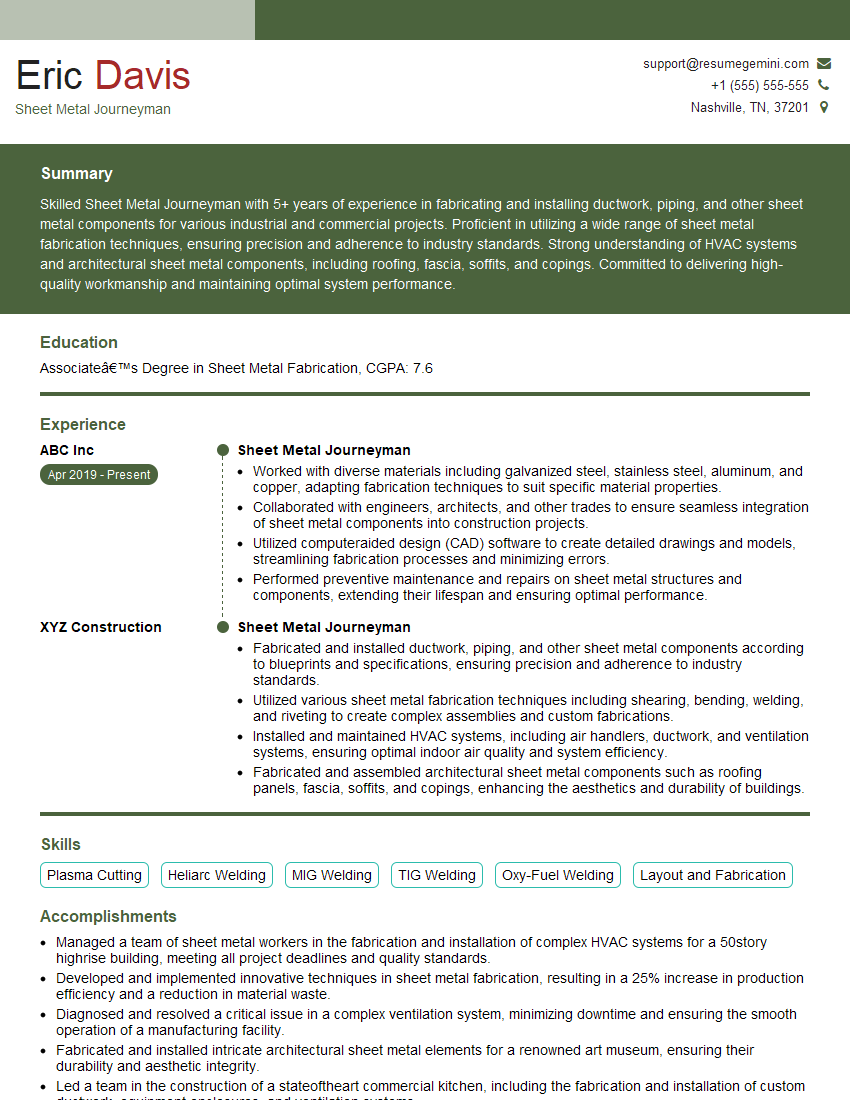

Eric Davis

Sheet Metal Journeyman

Summary

Skilled Sheet Metal Journeyman with 5+ years of experience in fabricating and installing ductwork, piping, and other sheet metal components for various industrial and commercial projects. Proficient in utilizing a wide range of sheet metal fabrication techniques, ensuring precision and adherence to industry standards. Strong understanding of HVAC systems and architectural sheet metal components, including roofing, fascia, soffits, and copings. Committed to delivering high-quality workmanship and maintaining optimal system performance.

Education

Associate’s Degree in Sheet Metal Fabrication

March 2015

Skills

- Plasma Cutting

- Heliarc Welding

- MIG Welding

- TIG Welding

- Oxy-Fuel Welding

- Layout and Fabrication

Work Experience

Sheet Metal Journeyman

- Worked with diverse materials including galvanized steel, stainless steel, aluminum, and copper, adapting fabrication techniques to suit specific material properties.

- Collaborated with engineers, architects, and other trades to ensure seamless integration of sheet metal components into construction projects.

- Utilized computeraided design (CAD) software to create detailed drawings and models, streamlining fabrication processes and minimizing errors.

- Performed preventive maintenance and repairs on sheet metal structures and components, extending their lifespan and ensuring optimal performance.

Sheet Metal Journeyman

- Fabricated and installed ductwork, piping, and other sheet metal components according to blueprints and specifications, ensuring precision and adherence to industry standards.

- Utilized various sheet metal fabrication techniques including shearing, bending, welding, and riveting to create complex assemblies and custom fabrications.

- Installed and maintained HVAC systems, including air handlers, ductwork, and ventilation systems, ensuring optimal indoor air quality and system efficiency.

- Fabricated and assembled architectural sheet metal components such as roofing panels, fascia, soffits, and copings, enhancing the aesthetics and durability of buildings.

Accomplishments

- Managed a team of sheet metal workers in the fabrication and installation of complex HVAC systems for a 50story highrise building, meeting all project deadlines and quality standards.

- Developed and implemented innovative techniques in sheet metal fabrication, resulting in a 25% increase in production efficiency and a reduction in material waste.

- Diagnosed and resolved a critical issue in a complex ventilation system, minimizing downtime and ensuring the smooth operation of a manufacturing facility.

- Fabricated and installed intricate architectural sheet metal elements for a renowned art museum, ensuring their durability and aesthetic integrity.

- Led a team in the construction of a stateoftheart commercial kitchen, including the fabrication and installation of custom ductwork, equipment enclosures, and ventilation systems.

Awards

- Received Craftsman of the Year award from Sheet Metal Workers International Association (SMWIA) for outstanding craftsmanship and dedication to the trade.

- Recognized with the Safety Star award for maintaining an exceptional safety record and promoting safe work practices at the job site.

- Honored with the Excellence in Apprenticeship award for mentoring and training new sheet metal apprentices, fostering their development and success in the field.

- Received the National Sheet Metal Worker of the Year award for exceptional contributions to the industry, including developing innovative tools and educational resources.

Certificates

- Certified Sheet Metal Journeyman

- NCCER Sheet Metal Journeyman Level

- AWS Certified Welder

- OSHA 30-Hour Construction Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Journeyman

- Highlight your experience and skills in fabricating and installing sheet metal components.

- Showcase your knowledge of HVAC systems and architectural sheet metal components.

- Emphasize your ability to work independently and as part of a team.

- Provide examples of projects where you have successfully applied your sheet metal fabrication skills.

Essential Experience Highlights for a Strong Sheet Metal Journeyman Resume

- Fabricate and install ductwork, piping, and other sheet metal components according to blueprints and specifications.

- Utilize various sheet metal fabrication techniques, including shearing, bending, welding, and riveting, to create complex assemblies and custom fabrications.

- Install and maintain HVAC systems, ensuring optimal indoor air quality and system efficiency.

- Fabricate and assemble architectural sheet metal components such as roofing panels, fascia, soffits, and copings.

- Collaborate with engineers, architects, and other trades to ensure seamless integration of sheet metal components into construction projects.

Frequently Asked Questions (FAQ’s) For Sheet Metal Journeyman

What are the key skills required to be a successful Sheet Metal Journeyman?

Key skills include proficiency in sheet metal fabrication techniques, knowledge of HVAC systems and architectural sheet metal components, and the ability to work independently and as part of a team.

What are the career opportunities for Sheet Metal Journeymen?

Sheet Metal Journeymen can advance to positions such as Foreman, Supervisor, or Project Manager.

What is the job outlook for Sheet Metal Journeymen?

The job outlook for Sheet Metal Journeymen is expected to be good in the coming years due to increased demand for construction and renovation projects.

What are the educational requirements to become a Sheet Metal Journeyman?

Typically, an Associate’s Degree in Sheet Metal Fabrication or a related field is required.

What are the typical working conditions for Sheet Metal Journeymen?

Sheet Metal Journeymen typically work in a shop or on construction sites, and may be exposed to noise, dust, and other hazards.