Are you a seasoned Sheet Metal Operator seeking a new career path? Discover our professionally built Sheet Metal Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

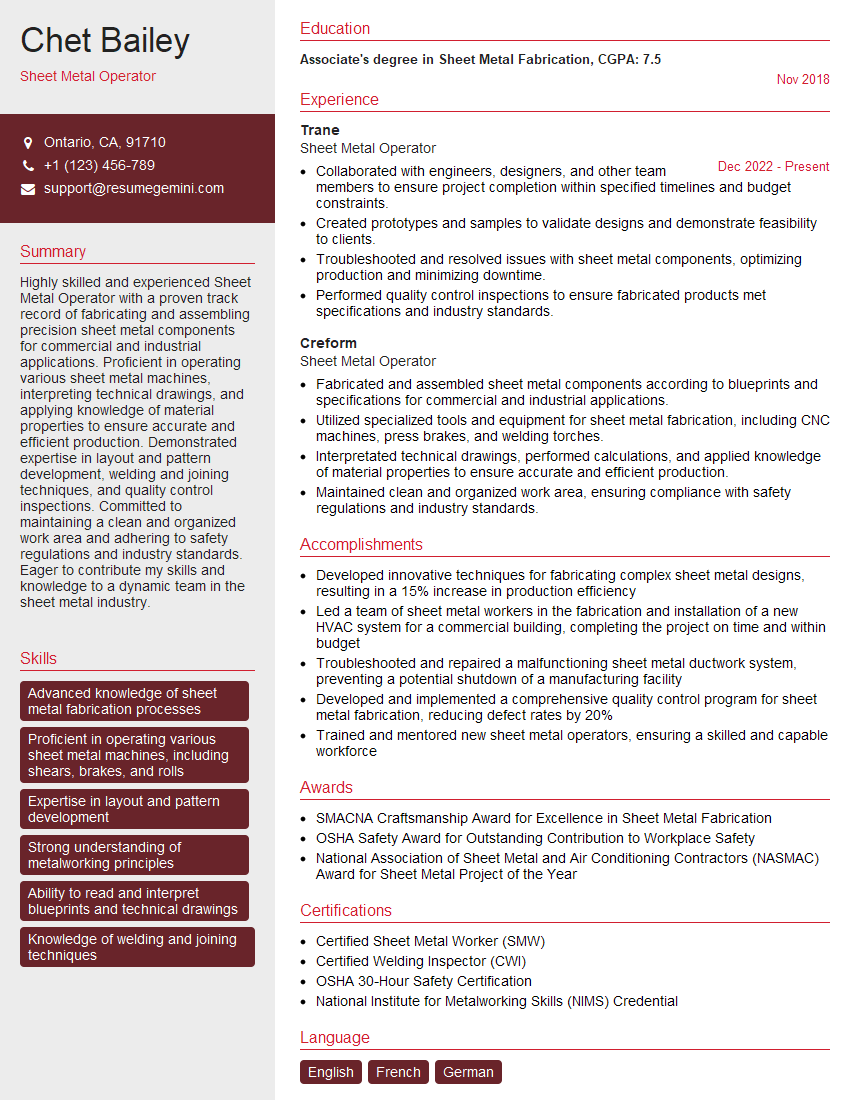

Chet Bailey

Sheet Metal Operator

Summary

Highly skilled and experienced Sheet Metal Operator with a proven track record of fabricating and assembling precision sheet metal components for commercial and industrial applications. Proficient in operating various sheet metal machines, interpreting technical drawings, and applying knowledge of material properties to ensure accurate and efficient production. Demonstrated expertise in layout and pattern development, welding and joining techniques, and quality control inspections. Committed to maintaining a clean and organized work area and adhering to safety regulations and industry standards. Eager to contribute my skills and knowledge to a dynamic team in the sheet metal industry.

Education

Associate’s degree in Sheet Metal Fabrication

November 2018

Skills

- Advanced knowledge of sheet metal fabrication processes

- Proficient in operating various sheet metal machines, including shears, brakes, and rolls

- Expertise in layout and pattern development

- Strong understanding of metalworking principles

- Ability to read and interpret blueprints and technical drawings

- Knowledge of welding and joining techniques

Work Experience

Sheet Metal Operator

- Collaborated with engineers, designers, and other team members to ensure project completion within specified timelines and budget constraints.

- Created prototypes and samples to validate designs and demonstrate feasibility to clients.

- Troubleshooted and resolved issues with sheet metal components, optimizing production and minimizing downtime.

- Performed quality control inspections to ensure fabricated products met specifications and industry standards.

Sheet Metal Operator

- Fabricated and assembled sheet metal components according to blueprints and specifications for commercial and industrial applications.

- Utilized specialized tools and equipment for sheet metal fabrication, including CNC machines, press brakes, and welding torches.

- Interpretated technical drawings, performed calculations, and applied knowledge of material properties to ensure accurate and efficient production.

- Maintained clean and organized work area, ensuring compliance with safety regulations and industry standards.

Accomplishments

- Developed innovative techniques for fabricating complex sheet metal designs, resulting in a 15% increase in production efficiency

- Led a team of sheet metal workers in the fabrication and installation of a new HVAC system for a commercial building, completing the project on time and within budget

- Troubleshooted and repaired a malfunctioning sheet metal ductwork system, preventing a potential shutdown of a manufacturing facility

- Developed and implemented a comprehensive quality control program for sheet metal fabrication, reducing defect rates by 20%

- Trained and mentored new sheet metal operators, ensuring a skilled and capable workforce

Awards

- SMACNA Craftsmanship Award for Excellence in Sheet Metal Fabrication

- OSHA Safety Award for Outstanding Contribution to Workplace Safety

- National Association of Sheet Metal and Air Conditioning Contractors (NASMAC) Award for Sheet Metal Project of the Year

Certificates

- Certified Sheet Metal Worker (SMW)

- Certified Welding Inspector (CWI)

- OSHA 30-Hour Safety Certification

- National Institute for Metalworking Skills (NIMS) Credential

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Operator

Highlight your skills and experience:

Emphasize your proficiency in operating sheet metal machines, interpreting technical drawings, and applying knowledge of material properties.Quantify your accomplishments:

Use numbers to demonstrate your impact on the company, such as the number of components fabricated or the percentage of projects completed on time and within budget.Showcase your attention to detail:

Highlight your commitment to quality control and adherence to safety regulations.Tailor your resume to the job description:

Carefully review the job description and tailor your resume to match the specific requirements of the position.Proofread your resume carefully:

Before submitting your resume, proofread it carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Sheet Metal Operator Resume

- Fabricated and assembled sheet metal components according to blueprints and specifications for commercial and industrial applications.

- Utilized specialized tools and equipment for sheet metal fabrication, including CNC machines, press brakes, and welding torches.

- Interpreted technical drawings, performed calculations, and applied knowledge of material properties to ensure accurate and efficient production.

- Created prototypes and samples to validate designs and demonstrate feasibility to clients.

- Troubleshooted and resolved issues with sheet metal components, optimizing production and minimizing downtime.

- Performed quality control inspections to ensure fabricated products met specifications and industry standards.

- Collaborated with engineers, designers, and other team members to ensure project completion within specified timelines and budget constraints.

Frequently Asked Questions (FAQ’s) For Sheet Metal Operator

What are the primary responsibilities of a Sheet Metal Operator?

Sheet Metal Operators are responsible for fabricating and assembling sheet metal components according to blueprints and specifications. They use specialized tools and equipment to cut, bend, weld, and join sheet metal into various shapes and sizes. They also interpret technical drawings, perform calculations, and apply knowledge of material properties to ensure accurate and efficient production.

What are the key skills required to be a successful Sheet Metal Operator?

Successful Sheet Metal Operators possess advanced knowledge of sheet metal fabrication processes, proficiency in operating various sheet metal machines, expertise in layout and pattern development, a strong understanding of metalworking principles, the ability to read and interpret blueprints and technical drawings, and knowledge of welding and joining techniques.

What industries employ Sheet Metal Operators?

Sheet Metal Operators are employed in a wide range of industries, including construction, manufacturing, automotive, aerospace, and electronics. They may work for companies that specialize in sheet metal fabrication or for companies that use sheet metal components in their products.

What is the average salary for a Sheet Metal Operator?

The average salary for a Sheet Metal Operator varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers was $50,360 in May 2021.

What are the career advancement opportunities for Sheet Metal Operators?

Sheet Metal Operators can advance their careers by gaining experience and developing their skills. They may become supervisors or managers, or they may specialize in a particular area of sheet metal fabrication, such as welding or layout.

What are the safety precautions that Sheet Metal Operators must follow?

Sheet Metal Operators must follow various safety precautions to protect themselves from hazards associated with their work. These precautions include wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs, and following established safety procedures when operating machinery.

What is the outlook for Sheet Metal Operators?

The outlook for Sheet Metal Operators is expected to be good over the next few years. The demand for sheet metal products is expected to increase as the construction and manufacturing industries grow.