Are you a seasoned Sheet Metal Technician seeking a new career path? Discover our professionally built Sheet Metal Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

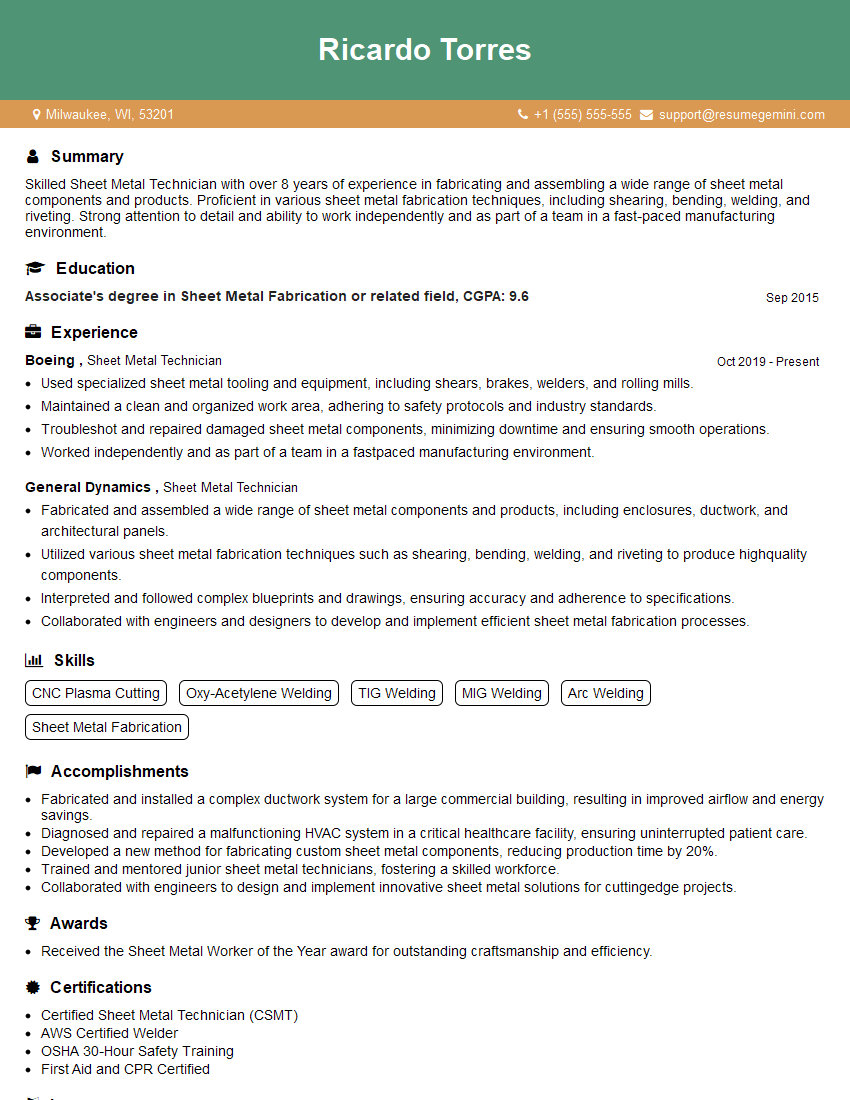

Ricardo Torres

Sheet Metal Technician

Summary

Skilled Sheet Metal Technician with over 8 years of experience in fabricating and assembling a wide range of sheet metal components and products. Proficient in various sheet metal fabrication techniques, including shearing, bending, welding, and riveting. Strong attention to detail and ability to work independently and as part of a team in a fast-paced manufacturing environment.

Education

Associate’s degree in Sheet Metal Fabrication or related field

September 2015

Skills

- CNC Plasma Cutting

- Oxy-Acetylene Welding

- TIG Welding

- MIG Welding

- Arc Welding

- Sheet Metal Fabrication

Work Experience

Sheet Metal Technician

- Used specialized sheet metal tooling and equipment, including shears, brakes, welders, and rolling mills.

- Maintained a clean and organized work area, adhering to safety protocols and industry standards.

- Troubleshot and repaired damaged sheet metal components, minimizing downtime and ensuring smooth operations.

- Worked independently and as part of a team in a fastpaced manufacturing environment.

Sheet Metal Technician

- Fabricated and assembled a wide range of sheet metal components and products, including enclosures, ductwork, and architectural panels.

- Utilized various sheet metal fabrication techniques such as shearing, bending, welding, and riveting to produce highquality components.

- Interpreted and followed complex blueprints and drawings, ensuring accuracy and adherence to specifications.

- Collaborated with engineers and designers to develop and implement efficient sheet metal fabrication processes.

Accomplishments

- Fabricated and installed a complex ductwork system for a large commercial building, resulting in improved airflow and energy savings.

- Diagnosed and repaired a malfunctioning HVAC system in a critical healthcare facility, ensuring uninterrupted patient care.

- Developed a new method for fabricating custom sheet metal components, reducing production time by 20%.

- Trained and mentored junior sheet metal technicians, fostering a skilled workforce.

- Collaborated with engineers to design and implement innovative sheet metal solutions for cuttingedge projects.

Awards

- Received the Sheet Metal Worker of the Year award for outstanding craftsmanship and efficiency.

Certificates

- Certified Sheet Metal Technician (CSMT)

- AWS Certified Welder

- OSHA 30-Hour Safety Training

- First Aid and CPR Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Technician

- Highlight your skills and experience in sheet metal fabrication techniques, such as shearing, bending, welding, and riveting

- Showcase your ability to read and interpret blueprints and drawings accurately

- Emphasize your experience in using specialized sheet metal tooling and equipment

- Provide examples of how you have collaborated with engineers and designers to develop and implement efficient sheet metal fabrication processes

- Demonstrate your commitment to safety and quality by highlighting your adherence to industry standards and safety protocols

Essential Experience Highlights for a Strong Sheet Metal Technician Resume

- Fabricated and assembled sheet metal components and products according to blueprints and specifications

- Utilized various sheet metal fabrication techniques such as shearing, bending, welding, and riveting

- Collaborated with engineers and designers to develop and implement efficient sheet metal fabrication processes

- Used specialized sheet metal tooling and equipment, including shears, brakes, welders, and rolling mills

- Maintained a clean and organized work area, adhering to safety protocols and industry standards

- Troubleshot and repaired damaged sheet metal components, minimizing downtime and ensuring smooth operations

- Worked independently and as part of a team in a fast-paced manufacturing environment

Frequently Asked Questions (FAQ’s) For Sheet Metal Technician

What are the key skills required to be a successful Sheet Metal Technician?

The key skills required to be a successful Sheet Metal Technician include proficiency in sheet metal fabrication techniques such as shearing, bending, welding, and riveting. Additionally, strong attention to detail, ability to read and interpret blueprints and drawings accurately, and experience in using specialized sheet metal tooling and equipment are essential.

What are the typical job responsibilities of a Sheet Metal Technician?

Typical job responsibilities of a Sheet Metal Technician include fabricating and assembling sheet metal components and products according to blueprints and specifications, collaborating with engineers and designers to develop and implement efficient sheet metal fabrication processes, using specialized sheet metal tooling and equipment, and maintaining a clean and organized work area.

What are the career advancement opportunities for Sheet Metal Technicians?

Sheet Metal Technicians with experience and expertise can advance to supervisory or management roles, such as Sheet Metal Shop Supervisor or Sheet Metal Fabrication Manager. Additionally, they may specialize in a particular area of sheet metal fabrication, such as welding or design.

What is the job outlook for Sheet Metal Technicians?

The job outlook for Sheet Metal Technicians is expected to be good in the coming years due to the increasing demand for skilled tradespeople in the manufacturing industry. The growth in construction and infrastructure projects is also expected to contribute to the demand for Sheet Metal Technicians.

What are the educational requirements to become a Sheet Metal Technician?

While a high school diploma or equivalent is typically the minimum educational requirement to become a Sheet Metal Technician, many employers prefer candidates with an associate’s degree in Sheet Metal Fabrication or a related field. Additionally, apprenticeships and on-the-job training programs are available for individuals seeking to enter the field.

What are the safety precautions that Sheet Metal Technicians must follow?

Sheet Metal Technicians must follow various safety precautions, including wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection. They must also be aware of the hazards associated with working with sharp tools and machinery, and follow proper lockout/tagout procedures to prevent accidents.

What is the average salary for Sheet Metal Technicians?

The average salary for Sheet Metal Technicians varies depending on factors such as experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers was $56,930 in May 2021.