Are you a seasoned Sheet Metal Worker Apprentice seeking a new career path? Discover our professionally built Sheet Metal Worker Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

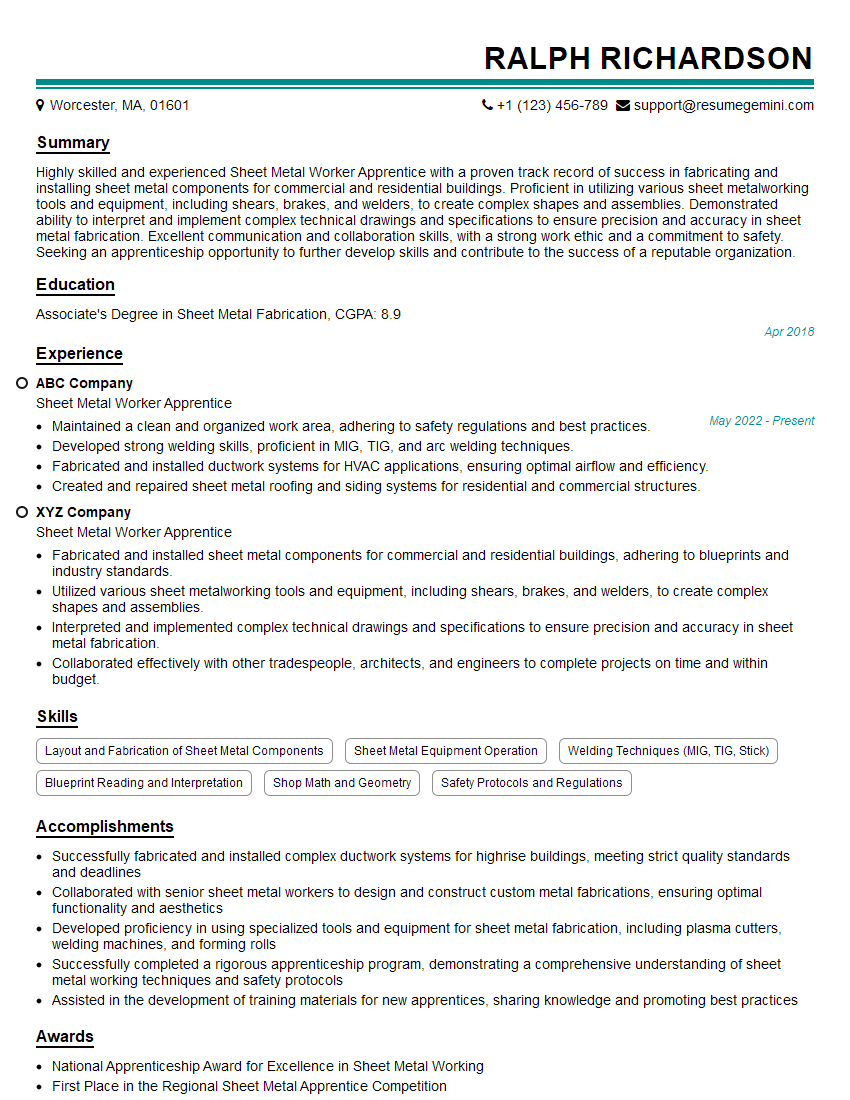

Ralph Richardson

Sheet Metal Worker Apprentice

Summary

Highly skilled and experienced Sheet Metal Worker Apprentice with a proven track record of success in fabricating and installing sheet metal components for commercial and residential buildings. Proficient in utilizing various sheet metalworking tools and equipment, including shears, brakes, and welders, to create complex shapes and assemblies. Demonstrated ability to interpret and implement complex technical drawings and specifications to ensure precision and accuracy in sheet metal fabrication. Excellent communication and collaboration skills, with a strong work ethic and a commitment to safety. Seeking an apprenticeship opportunity to further develop skills and contribute to the success of a reputable organization.

Education

Associate’s Degree in Sheet Metal Fabrication

April 2018

Skills

- Layout and Fabrication of Sheet Metal Components

- Sheet Metal Equipment Operation

- Welding Techniques (MIG, TIG, Stick)

- Blueprint Reading and Interpretation

- Shop Math and Geometry

- Safety Protocols and Regulations

Work Experience

Sheet Metal Worker Apprentice

- Maintained a clean and organized work area, adhering to safety regulations and best practices.

- Developed strong welding skills, proficient in MIG, TIG, and arc welding techniques.

- Fabricated and installed ductwork systems for HVAC applications, ensuring optimal airflow and efficiency.

- Created and repaired sheet metal roofing and siding systems for residential and commercial structures.

Sheet Metal Worker Apprentice

- Fabricated and installed sheet metal components for commercial and residential buildings, adhering to blueprints and industry standards.

- Utilized various sheet metalworking tools and equipment, including shears, brakes, and welders, to create complex shapes and assemblies.

- Interpreted and implemented complex technical drawings and specifications to ensure precision and accuracy in sheet metal fabrication.

- Collaborated effectively with other tradespeople, architects, and engineers to complete projects on time and within budget.

Accomplishments

- Successfully fabricated and installed complex ductwork systems for highrise buildings, meeting strict quality standards and deadlines

- Collaborated with senior sheet metal workers to design and construct custom metal fabrications, ensuring optimal functionality and aesthetics

- Developed proficiency in using specialized tools and equipment for sheet metal fabrication, including plasma cutters, welding machines, and forming rolls

- Successfully completed a rigorous apprenticeship program, demonstrating a comprehensive understanding of sheet metal working techniques and safety protocols

- Assisted in the development of training materials for new apprentices, sharing knowledge and promoting best practices

Awards

- National Apprenticeship Award for Excellence in Sheet Metal Working

- First Place in the Regional Sheet Metal Apprentice Competition

- Top Apprentice of the Year by the Sheet Metal Workers Local Union

Certificates

- OSHA 30-Hour Construction Safety Training

- National Center for Construction Education and Research (NCCER) Core Curriculum

- Certified Welding Inspector (CWI)

- Sheet Metal Workers International Association (SMWIA) Apprenticeship Program

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Worker Apprentice

- Highlight your technical skills and experience in sheet metal fabrication, including your proficiency in using various tools and equipment.

- Showcase your ability to read and interpret complex drawings and specifications, ensuring accuracy and precision in your work.

- Emphasize your collaborative nature and ability to work effectively with others in a team environment.

- Demonstrate your commitment to safety and your adherence to industry regulations and best practices.

- Tailor your resume to the specific requirements of the apprenticeship program you are applying for.

Essential Experience Highlights for a Strong Sheet Metal Worker Apprentice Resume

- Fabricate and install sheet metal components for commercial and residential buildings, adhering to blueprints and industry standards.

- Utilize various sheet metalworking tools and equipment, including shears, brakes, and welders, to create complex shapes and assemblies.

- Interpret and implement complex technical drawings and specifications to ensure precision and accuracy in sheet metal fabrication.

- Collaborate effectively with other tradespeople, architects, and engineers to complete projects on time and within budget.

- Maintain a clean and organized work area, adhering to safety regulations and best practices.

- Develop strong welding skills, proficient in MIG, TIG, and arc welding techniques.

- Fabricate and install ductwork systems for HVAC applications, ensuring optimal airflow and efficiency.

Frequently Asked Questions (FAQ’s) For Sheet Metal Worker Apprentice

What are the educational requirements to become a Sheet Metal Worker Apprentice?

Typically, a high school diploma or equivalent is required. Some employers may prefer candidates with an associate’s degree or certification in a related field, such as sheet metal fabrication or welding.

What are the job responsibilities of a Sheet Metal Worker Apprentice?

Sheet Metal Worker Apprentices assist in the fabrication and installation of sheet metal components for various structures, including buildings, ductwork, and roofing systems. They may also perform tasks such as reading blueprints, cutting and bending sheet metal, welding, and soldering.

What are the career advancement opportunities for Sheet Metal Worker Apprentices?

With experience and additional training, Sheet Metal Worker Apprentices can advance to become Journey-Level Sheet Metal Workers. They may also specialize in areas such as architectural sheet metal, HVAC, or welding.

What are the earning prospects for Sheet Metal Worker Apprentices?

The earning potential for Sheet Metal Worker Apprentices varies depending on factors such as experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual wage for Sheet Metal Workers was $51,800 in May 2021.

What are the safety precautions that Sheet Metal Worker Apprentices should take?

Sheet Metal Worker Apprentices should adhere to all safety regulations and guidelines. This includes wearing appropriate personal protective equipment, such as gloves, safety glasses, and respirators, and following safe work practices to prevent injuries.

What are the key skills and qualities that employers look for in Sheet Metal Worker Apprentices?

Employers typically seek Sheet Metal Worker Apprentices who are physically fit, have good manual dexterity, and are able to work independently and as part of a team. They should also have a strong work ethic, be detail-oriented, and have a willingness to learn and develop their skills.

How can I prepare for a career as a Sheet Metal Worker Apprentice?

To prepare for a career as a Sheet Metal Worker Apprentice, you can take courses in math, science, and drafting. You can also gain hands-on experience through vocational training programs or by working as a helper in the sheet metal industry.

What are the benefits of becoming a Sheet Metal Worker Apprentice?

Becoming a Sheet Metal Worker Apprentice offers several benefits, including the opportunity to learn a valuable trade, earn a competitive salary, and advance your career in the construction industry.