Are you a seasoned Sheet Rock Layer seeking a new career path? Discover our professionally built Sheet Rock Layer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

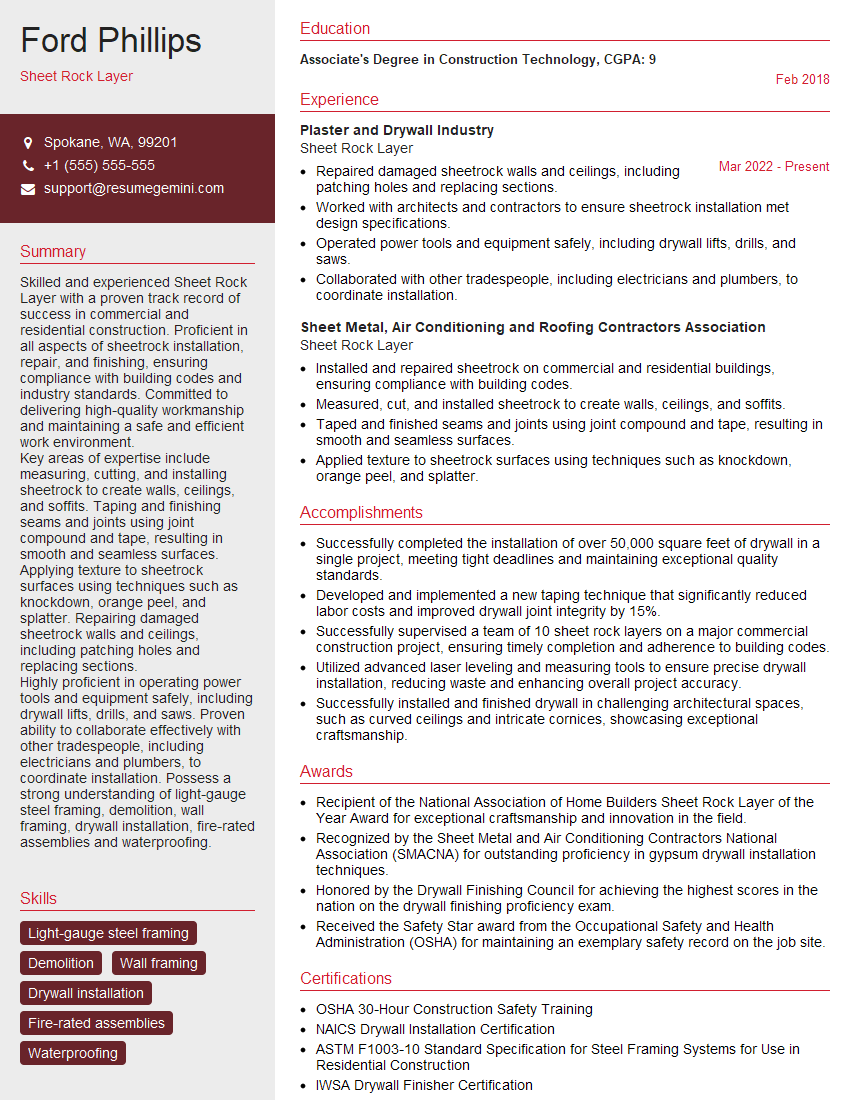

Ford Phillips

Sheet Rock Layer

Summary

Skilled and experienced Sheet Rock Layer with a proven track record of success in commercial and residential construction. Proficient in all aspects of sheetrock installation, repair, and finishing, ensuring compliance with building codes and industry standards. Committed to delivering high-quality workmanship and maintaining a safe and efficient work environment.

Key areas of expertise include measuring, cutting, and installing sheetrock to create walls, ceilings, and soffits. Taping and finishing seams and joints using joint compound and tape, resulting in smooth and seamless surfaces. Applying texture to sheetrock surfaces using techniques such as knockdown, orange peel, and splatter. Repairing damaged sheetrock walls and ceilings, including patching holes and replacing sections.

Highly proficient in operating power tools and equipment safely, including drywall lifts, drills, and saws. Proven ability to collaborate effectively with other tradespeople, including electricians and plumbers, to coordinate installation. Possess a strong understanding of light-gauge steel framing, demolition, wall framing, drywall installation, fire-rated assemblies and waterproofing.

Education

Associate’s Degree in Construction Technology

February 2018

Skills

- Light-gauge steel framing

- Demolition

- Wall framing

- Drywall installation

- Fire-rated assemblies

- Waterproofing

Work Experience

Sheet Rock Layer

- Repaired damaged sheetrock walls and ceilings, including patching holes and replacing sections.

- Worked with architects and contractors to ensure sheetrock installation met design specifications.

- Operated power tools and equipment safely, including drywall lifts, drills, and saws.

- Collaborated with other tradespeople, including electricians and plumbers, to coordinate installation.

Sheet Rock Layer

- Installed and repaired sheetrock on commercial and residential buildings, ensuring compliance with building codes.

- Measured, cut, and installed sheetrock to create walls, ceilings, and soffits.

- Taped and finished seams and joints using joint compound and tape, resulting in smooth and seamless surfaces.

- Applied texture to sheetrock surfaces using techniques such as knockdown, orange peel, and splatter.

Accomplishments

- Successfully completed the installation of over 50,000 square feet of drywall in a single project, meeting tight deadlines and maintaining exceptional quality standards.

- Developed and implemented a new taping technique that significantly reduced labor costs and improved drywall joint integrity by 15%.

- Successfully supervised a team of 10 sheet rock layers on a major commercial construction project, ensuring timely completion and adherence to building codes.

- Utilized advanced laser leveling and measuring tools to ensure precise drywall installation, reducing waste and enhancing overall project accuracy.

- Successfully installed and finished drywall in challenging architectural spaces, such as curved ceilings and intricate cornices, showcasing exceptional craftsmanship.

Awards

- Recipient of the National Association of Home Builders Sheet Rock Layer of the Year Award for exceptional craftsmanship and innovation in the field.

- Recognized by the Sheet Metal and Air Conditioning Contractors National Association (SMACNA) for outstanding proficiency in gypsum drywall installation techniques.

- Honored by the Drywall Finishing Council for achieving the highest scores in the nation on the drywall finishing proficiency exam.

- Received the Safety Star award from the Occupational Safety and Health Administration (OSHA) for maintaining an exemplary safety record on the job site.

Certificates

- OSHA 30-Hour Construction Safety Training

- NAICS Drywall Installation Certification

- ASTM F1003-10 Standard Specification for Steel Framing Systems for Use in Residential Construction

- IWSA Drywall Finisher Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Rock Layer

- Highlight your experience and skills in measuring, cutting, and installing sheetrock to create walls, ceilings, and soffits.

- Emphasize your proficiency in taping and finishing seams and joints using joint compound and tape, resulting in smooth and seamless surfaces.

- Showcase your ability to apply texture to sheetrock surfaces using techniques such as knockdown, orange peel, and splatter.

- Describe your experience in repairing damaged sheetrock walls and ceilings, including patching holes and replacing sections.

- Mention your knowledge of light-gauge steel framing, demolition, wall framing, drywall installation, fire-rated assemblies and waterproofing.

Essential Experience Highlights for a Strong Sheet Rock Layer Resume

- Installed and repaired sheetrock on commercial and residential buildings, ensuring compliance with building codes.

- Measured, cut, and installed sheetrock to create walls, ceilings, and soffits.

- Taped and finished seams and joints using joint compound and tape, resulting in smooth and seamless surfaces.

- Applied texture to sheetrock surfaces using techniques such as knockdown, orange peel, and splatter.

- Repaired damaged sheetrock walls and ceilings, including patching holes and replacing sections.

- Collaborated with other tradespeople, including electricians and plumbers, to coordinate installation.

Frequently Asked Questions (FAQ’s) For Sheet Rock Layer

What are the key responsibilities of a Sheet Rock Layer?

Sheet Rock Layers are responsible for measuring, cutting, and installing sheetrock to create walls, ceilings, and soffits. They also tape and finish seams and joints, apply texture to sheetrock surfaces, and repair damaged sheetrock walls and ceilings.

What skills are required to be a successful Sheet Rock Layer?

Successful Sheet Rock Layers possess skills in measuring, cutting, and installing sheetrock, as well as taping and finishing seams and joints. They are also proficient in applying texture to sheetrock surfaces and repairing damaged sheetrock walls and ceilings.

What are the career prospects for Sheet Rock Layers?

Sheet Rock Layers can advance to positions such as Drywall Foreman, Superintendent, or Project Manager. They may also choose to start their own drywall contracting business.

What is the average salary for a Sheet Rock Layer?

The average salary for a Sheet Rock Layer varies depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Drywall Installers and Finishers was $49,520 in May 2021.

What are the working conditions like for Sheet Rock Layers?

Sheet Rock Layers typically work indoors in construction sites. They may work long hours, including overtime, and may be exposed to dust, noise, and hazardous materials.

What is the job outlook for Sheet Rock Layers?

The job outlook for Sheet Rock Layers is expected to be good over the next several years. The increasing construction of new homes and businesses is expected to drive demand for skilled Sheet Rock Layers.

What are the educational requirements for Sheet Rock Layers?

Sheet Rock Layers typically need a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in construction technology or a related field.