Are you a seasoned Shirring Machine Operator seeking a new career path? Discover our professionally built Shirring Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

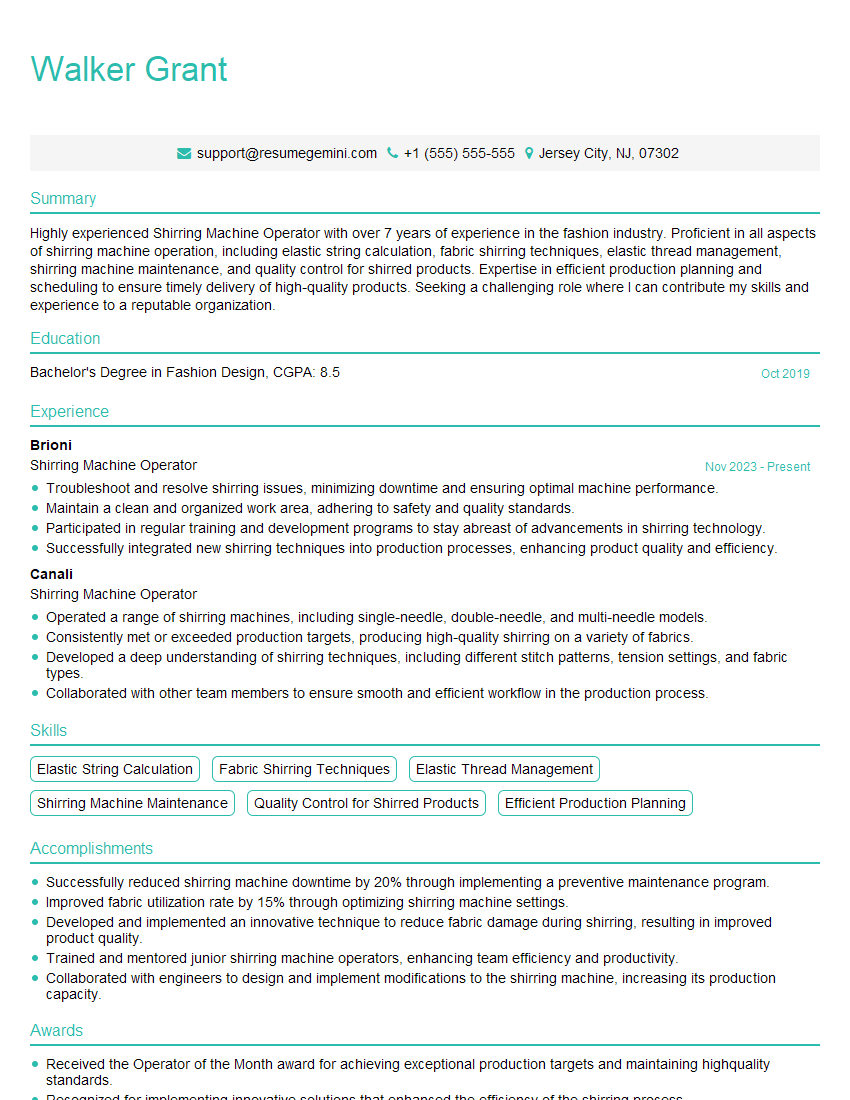

Walker Grant

Shirring Machine Operator

Summary

Highly experienced Shirring Machine Operator with over 7 years of experience in the fashion industry. Proficient in all aspects of shirring machine operation, including elastic string calculation, fabric shirring techniques, elastic thread management, shirring machine maintenance, and quality control for shirred products. Expertise in efficient production planning and scheduling to ensure timely delivery of high-quality products. Seeking a challenging role where I can contribute my skills and experience to a reputable organization.

Education

Bachelor’s Degree in Fashion Design

October 2019

Skills

- Elastic String Calculation

- Fabric Shirring Techniques

- Elastic Thread Management

- Shirring Machine Maintenance

- Quality Control for Shirred Products

- Efficient Production Planning

Work Experience

Shirring Machine Operator

- Troubleshoot and resolve shirring issues, minimizing downtime and ensuring optimal machine performance.

- Maintain a clean and organized work area, adhering to safety and quality standards.

- Participated in regular training and development programs to stay abreast of advancements in shirring technology.

- Successfully integrated new shirring techniques into production processes, enhancing product quality and efficiency.

Shirring Machine Operator

- Operated a range of shirring machines, including single-needle, double-needle, and multi-needle models.

- Consistently met or exceeded production targets, producing high-quality shirring on a variety of fabrics.

- Developed a deep understanding of shirring techniques, including different stitch patterns, tension settings, and fabric types.

- Collaborated with other team members to ensure smooth and efficient workflow in the production process.

Accomplishments

- Successfully reduced shirring machine downtime by 20% through implementing a preventive maintenance program.

- Improved fabric utilization rate by 15% through optimizing shirring machine settings.

- Developed and implemented an innovative technique to reduce fabric damage during shirring, resulting in improved product quality.

- Trained and mentored junior shirring machine operators, enhancing team efficiency and productivity.

- Collaborated with engineers to design and implement modifications to the shirring machine, increasing its production capacity.

Awards

- Received the Operator of the Month award for achieving exceptional production targets and maintaining highquality standards.

- Recognized for implementing innovative solutions that enhanced the efficiency of the shirring process.

- Recipient of the Safety Excellence Award for maintaining an accidentfree working environment.

- Recognized for outstanding contribution to the implementation of a new shirring technology.

Certificates

- Shirring Machine Operator Certification

- Lean Manufacturing Practitioner Certification

- Quality Control Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shirring Machine Operator

- Highlight your experience in operating and maintaining shirring machines.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Showcase your knowledge of fabric shirring techniques and elastic thread management.

- Emphasize your commitment to quality control and meeting industry standards.

Essential Experience Highlights for a Strong Shirring Machine Operator Resume

- Operate and maintain shirring machines to create shirred fabrics and garments

- Calculate and adjust elastic string tension to achieve the desired shirring effect

- Troubleshoot and resolve machine malfunctions to minimize downtime

- Inspect and ensure the quality of shirred products to meet company standards

- Maintain a clean and organized work area to ensure safety and efficiency

- Follow production schedules and meet deadlines to ensure timely delivery of orders

- Work independently and as part of a team to achieve production goals

Frequently Asked Questions (FAQ’s) For Shirring Machine Operator

What are the key skills required to be a successful Shirring Machine Operator?

Key skills include: elastic string calculation, fabric shirring techniques, elastic thread management, shirring machine maintenance, quality control for shirred products, and efficient production planning.

What is the work environment like for a Shirring Machine Operator?

Work environments for Shirring Machine Operators typically involve working in production facilities or factories, often in a team setting. The job requires physical stamina as it involves standing and operating machinery for extended periods.

What are the career advancement opportunities for a Shirring Machine Operator?

With experience and additional training, Shirring Machine Operators may advance to roles such as Production Supervisor, Quality Control Inspector, or even start their own shirring business.

What is the average salary for a Shirring Machine Operator?

The average salary for a Shirring Machine Operator varies depending on experience, location, and company size. According to Salary.com, the average salary range is between $15-$25 per hour.

What are the job outlook prospects for Shirring Machine Operators?

The job outlook for Shirring Machine Operators is expected to grow faster than average, as the demand for shirred fabrics and garments continues to increase in the fashion industry.

What type of training is required to become a Shirring Machine Operator?

While formal training programs are not typically required, most Shirring Machine Operators receive on-the-job training from experienced operators or supervisors.

Are there any certifications available for Shirring Machine Operators?

Currently, there are no industry-wide certifications specifically for Shirring Machine Operators. However, obtaining certifications in related areas, such as sewing machine operation or textile manufacturing, can enhance your skills and credibility.

What are the safety precautions that Shirring Machine Operators should follow?

Important safety precautions include wearing appropriate safety gear, following lockout/tagout procedures, and maintaining a clean and organized work area to prevent accidents and injuries.