Are you a seasoned Shop Cooper seeking a new career path? Discover our professionally built Shop Cooper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

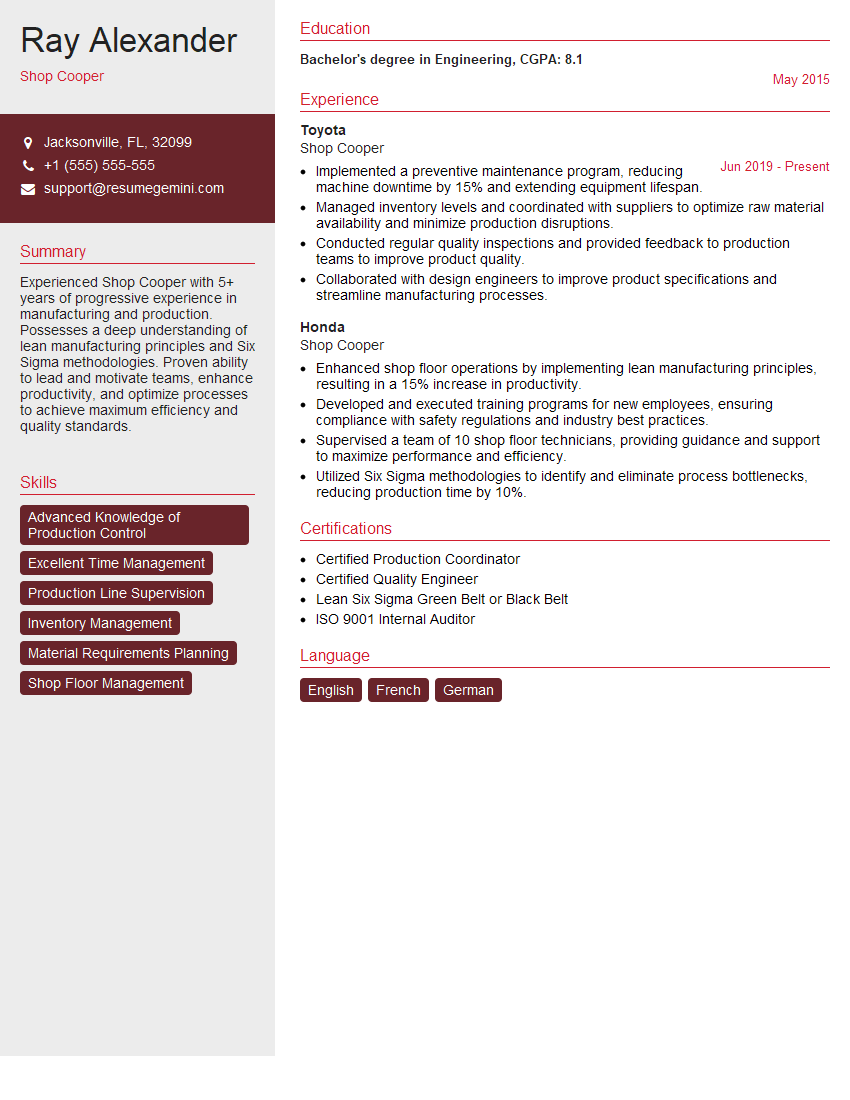

Ray Alexander

Shop Cooper

Summary

Experienced Shop Cooper with 5+ years of progressive experience in manufacturing and production. Possesses a deep understanding of lean manufacturing principles and Six Sigma methodologies. Proven ability to lead and motivate teams, enhance productivity, and optimize processes to achieve maximum efficiency and quality standards.

Education

Bachelor’s degree in Engineering

May 2015

Skills

- Advanced Knowledge of Production Control

- Excellent Time Management

- Production Line Supervision

- Inventory Management

- Material Requirements Planning

- Shop Floor Management

Work Experience

Shop Cooper

- Implemented a preventive maintenance program, reducing machine downtime by 15% and extending equipment lifespan.

- Managed inventory levels and coordinated with suppliers to optimize raw material availability and minimize production disruptions.

- Conducted regular quality inspections and provided feedback to production teams to improve product quality.

- Collaborated with design engineers to improve product specifications and streamline manufacturing processes.

Shop Cooper

- Enhanced shop floor operations by implementing lean manufacturing principles, resulting in a 15% increase in productivity.

- Developed and executed training programs for new employees, ensuring compliance with safety regulations and industry best practices.

- Supervised a team of 10 shop floor technicians, providing guidance and support to maximize performance and efficiency.

- Utilized Six Sigma methodologies to identify and eliminate process bottlenecks, reducing production time by 10%.

Certificates

- Certified Production Coordinator

- Certified Quality Engineer

- Lean Six Sigma Green Belt or Black Belt

- ISO 9001 Internal Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shop Cooper

- Highlight your expertise in lean manufacturing principles and Six Sigma methodologies.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your leadership and team management skills, emphasizing your ability to motivate and guide teams effectively.

- Emphasize your ability to identify and resolve production issues, reducing downtime and improving efficiency.

Essential Experience Highlights for a Strong Shop Cooper Resume

- Implement and manage lean manufacturing principles to optimize production processes and increase productivity

- Develop and execute training programs for new and existing employees to ensure compliance with safety regulations and industry best practices

- Supervise and lead teams of shop floor technicians, providing guidance and support to maximize performance and efficiency

- Utilize Six Sigma methodologies to identify and eliminate process bottlenecks, reducing production time and improving quality

- Implement and manage preventive maintenance programs to minimize machine downtime and extend equipment lifespan

- Manage inventory levels and collaborate with suppliers to ensure timely availability of raw materials and minimize production disruptions

- Conduct regular quality inspections and provide feedback to production teams to improve product quality and customer satisfaction

Frequently Asked Questions (FAQ’s) For Shop Cooper

What are the primary responsibilities of a Shop Cooper?

Shop Coopers are responsible for overseeing and managing production operations on the shop floor. Their key duties include implementing lean manufacturing principles, optimizing processes, training and supervising teams, ensuring quality control, and collaborating with suppliers to maintain efficient production.

What qualifications are required to become a Shop Cooper?

Typically, a Bachelor’s degree in Engineering or a related field is required. Additionally, experience in manufacturing, production, or a related industry is highly sought after. Expertise in lean manufacturing principles and Six Sigma methodologies is often essential.

What are the career prospects for a Shop Cooper?

Shop Coopers with experience and a proven track record of success can advance to roles such as Production Manager, Operations Manager, or Plant Manager. They may also move into related fields such as consulting or training.

What are the key qualities and skills required of a Shop Cooper?

Strong leadership and team management skills, in-depth knowledge of manufacturing processes and lean principles, excellent communication and interpersonal skills, and the ability to work effectively under pressure are all highly desirable qualities for Shop Coopers.

What is the average salary range for a Shop Cooper?

Salaries for Shop Coopers can vary depending on experience, location, and industry. According to Salary.com, the average salary range for Shop Coopers in the United States is between $70,000 and $110,000 per year.

What are the benefits of working as a Shop Cooper?

Shop Coopers enjoy a dynamic and rewarding career with opportunities to make a direct impact on production efficiency and quality. They work closely with teams, solve problems, and contribute to the success of manufacturing operations.

What are some common challenges faced by Shop Coopers?

Shop Coopers may face challenges such as managing complex production processes, meeting tight deadlines, ensuring quality standards, and working under pressure. They also need to stay updated on the latest manufacturing technologies and best practices.