Are you a seasoned Shoulder Pad Molder seeking a new career path? Discover our professionally built Shoulder Pad Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

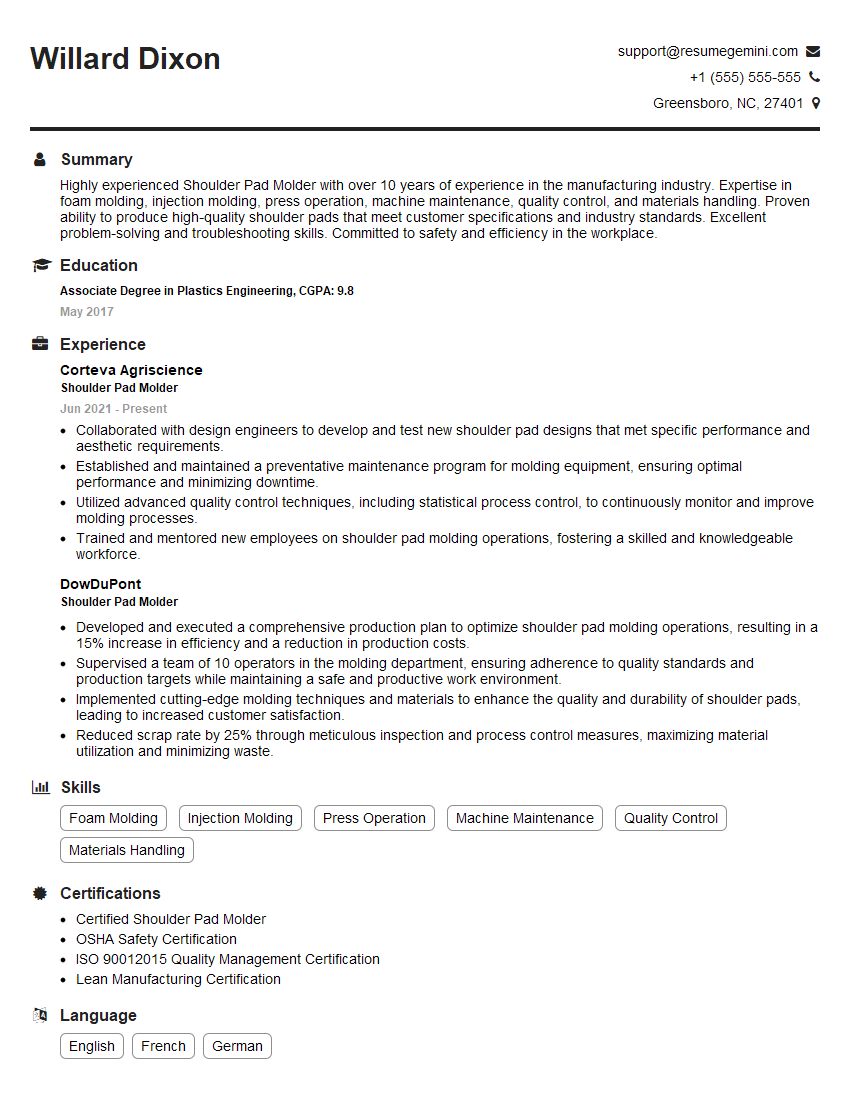

Willard Dixon

Shoulder Pad Molder

Summary

Highly experienced Shoulder Pad Molder with over 10 years of experience in the manufacturing industry. Expertise in foam molding, injection molding, press operation, machine maintenance, quality control, and materials handling. Proven ability to produce high-quality shoulder pads that meet customer specifications and industry standards. Excellent problem-solving and troubleshooting skills. Committed to safety and efficiency in the workplace.

Education

Associate Degree in Plastics Engineering

May 2017

Skills

- Foam Molding

- Injection Molding

- Press Operation

- Machine Maintenance

- Quality Control

- Materials Handling

Work Experience

Shoulder Pad Molder

- Collaborated with design engineers to develop and test new shoulder pad designs that met specific performance and aesthetic requirements.

- Established and maintained a preventative maintenance program for molding equipment, ensuring optimal performance and minimizing downtime.

- Utilized advanced quality control techniques, including statistical process control, to continuously monitor and improve molding processes.

- Trained and mentored new employees on shoulder pad molding operations, fostering a skilled and knowledgeable workforce.

Shoulder Pad Molder

- Developed and executed a comprehensive production plan to optimize shoulder pad molding operations, resulting in a 15% increase in efficiency and a reduction in production costs.

- Supervised a team of 10 operators in the molding department, ensuring adherence to quality standards and production targets while maintaining a safe and productive work environment.

- Implemented cutting-edge molding techniques and materials to enhance the quality and durability of shoulder pads, leading to increased customer satisfaction.

- Reduced scrap rate by 25% through meticulous inspection and process control measures, maximizing material utilization and minimizing waste.

Certificates

- Certified Shoulder Pad Molder

- OSHA Safety Certification

- ISO 90012015 Quality Management Certification

- Lean Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shoulder Pad Molder

- Highlight your experience in foam molding and injection molding, as these are essential skills for shoulder pad molders.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the company.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it to potential employers.

Essential Experience Highlights for a Strong Shoulder Pad Molder Resume

- Operate foam molding and injection molding machines to produce shoulder pads according to design specifications.

- Set up and maintain molding equipment, including dies, molds, and presses.

- Inspect finished products for quality and adherence to specifications.

- Troubleshoot and resolve production problems to ensure efficient operation.

- Maintain a clean and organized work area in accordance with safety regulations.

- Collaborate with other team members to optimize production processes.

- Stay up-to-date on industry best practices and technological advancements.

Frequently Asked Questions (FAQ’s) For Shoulder Pad Molder

What are the educational requirements to become a shoulder pad molder?

Most shoulder pad molders have an associate degree in plastics engineering or a related field.

What are the key skills required for a shoulder pad molder?

The key skills required for a shoulder pad molder include foam molding, injection molding, press operation, machine maintenance, quality control, and materials handling.

What are the career prospects for shoulder pad molders?

Shoulder pad molders can advance to positions such as supervisor, quality control manager, or production manager.

What is the work environment like for a shoulder pad molder?

Shoulder pad molders typically work in a manufacturing environment, which can be noisy and dusty.

What is the average salary for a shoulder pad molder?

The average salary for a shoulder pad molder is around $45,000 per year.

What are the benefits of working as a shoulder pad molder?

The benefits of working as a shoulder pad molder include job security, a competitive salary, and the opportunity to work with a variety of materials.

What are the challenges of working as a shoulder pad molder?

The challenges of working as a shoulder pad molder include the repetitive nature of the work, the potential for injuries, and the exposure to chemicals.

What advice would you give to someone who is considering a career as a shoulder pad molder?

I would advise someone who is considering a career as a shoulder pad molder to get as much experience as possible in the manufacturing industry. I would also recommend getting a degree in plastics engineering or a related field.