Are you a seasoned Single Needle Tufting Machine Operator seeking a new career path? Discover our professionally built Single Needle Tufting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

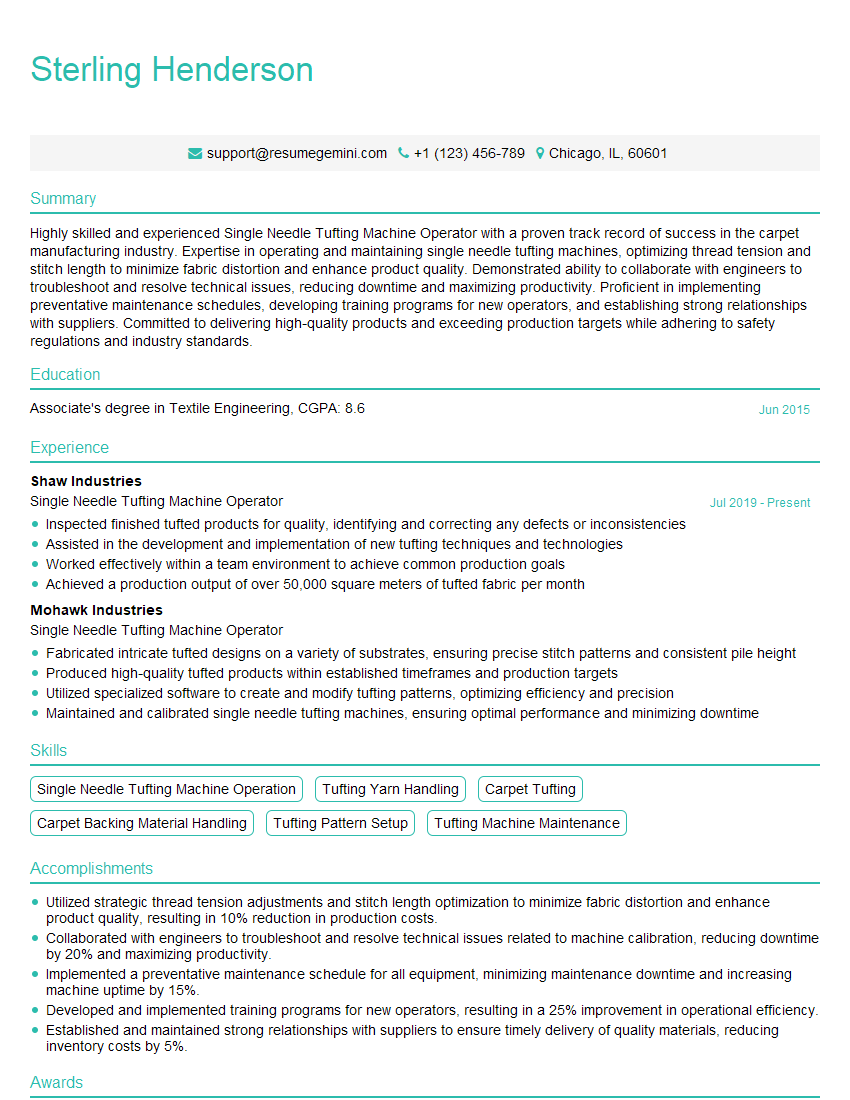

Sterling Henderson

Single Needle Tufting Machine Operator

Summary

Highly skilled and experienced Single Needle Tufting Machine Operator with a proven track record of success in the carpet manufacturing industry. Expertise in operating and maintaining single needle tufting machines, optimizing thread tension and stitch length to minimize fabric distortion and enhance product quality. Demonstrated ability to collaborate with engineers to troubleshoot and resolve technical issues, reducing downtime and maximizing productivity. Proficient in implementing preventative maintenance schedules, developing training programs for new operators, and establishing strong relationships with suppliers. Committed to delivering high-quality products and exceeding production targets while adhering to safety regulations and industry standards.

Education

Associate’s degree in Textile Engineering

June 2015

Skills

- Single Needle Tufting Machine Operation

- Tufting Yarn Handling

- Carpet Tufting

- Carpet Backing Material Handling

- Tufting Pattern Setup

- Tufting Machine Maintenance

Work Experience

Single Needle Tufting Machine Operator

- Inspected finished tufted products for quality, identifying and correcting any defects or inconsistencies

- Assisted in the development and implementation of new tufting techniques and technologies

- Worked effectively within a team environment to achieve common production goals

- Achieved a production output of over 50,000 square meters of tufted fabric per month

Single Needle Tufting Machine Operator

- Fabricated intricate tufted designs on a variety of substrates, ensuring precise stitch patterns and consistent pile height

- Produced high-quality tufted products within established timeframes and production targets

- Utilized specialized software to create and modify tufting patterns, optimizing efficiency and precision

- Maintained and calibrated single needle tufting machines, ensuring optimal performance and minimizing downtime

Accomplishments

- Utilized strategic thread tension adjustments and stitch length optimization to minimize fabric distortion and enhance product quality, resulting in 10% reduction in production costs.

- Collaborated with engineers to troubleshoot and resolve technical issues related to machine calibration, reducing downtime by 20% and maximizing productivity.

- Implemented a preventative maintenance schedule for all equipment, minimizing maintenance downtime and increasing machine uptime by 15%.

- Developed and implemented training programs for new operators, resulting in a 25% improvement in operational efficiency.

- Established and maintained strong relationships with suppliers to ensure timely delivery of quality materials, reducing inventory costs by 5%.

Awards

- Recognized for exceptional performance and contributions to the team, receiving the Employee of the Month Award three consecutive times.

- Awarded the Production Excellence Award for consistently exceeding production targets and maintaining high levels of quality.

- Received the Safety Champion Award for dedication to promoting and maintaining a safe working environment.

- Recognized for outstanding customer service, receiving the Excellence in Customer Relations Award.

Certificates

- Tufting Machine Operator Certification

- Carpet and Rug Institute (CRI) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Single Needle Tufting Machine Operator

Highlight your technical skills and experience.

Employers are looking for candidates who have a strong understanding of single needle tufting machines and can operate them efficiently. Be sure to emphasize your experience in adjusting thread tension and stitch length, troubleshooting technical issues, and implementing preventative maintenance schedules.Quantify your accomplishments.

When possible, use numbers to demonstrate the impact of your work. For example, you could mention that you reduced production costs by 10% or improved operational efficiency by 25%.Tailor your resume to each job you apply for.

Take the time to read the job description carefully and highlight the skills and experience that are most relevant to the position.Proofread your resume carefully.

Make sure your resume is free of errors and that it is formatted in a professional manner.

Essential Experience Highlights for a Strong Single Needle Tufting Machine Operator Resume

- Operate and maintain single needle tufting machines to produce high-quality carpets

- Adjust thread tension and stitch length to minimize fabric distortion and enhance product quality

- Collaborate with engineers to troubleshoot and resolve technical issues related to machine calibration

- Implement preventative maintenance schedules for all equipment to minimize downtime and increase machine uptime

- Develop and implement training programs for new operators to improve operational efficiency

- Maintain strong relationships with suppliers to ensure timely delivery of quality materials

- Adhere to safety regulations and industry standards to ensure a safe and productive work environment

Frequently Asked Questions (FAQ’s) For Single Needle Tufting Machine Operator

What is a Single Needle Tufting Machine Operator?

A Single Needle Tufting Machine Operator is responsible for operating and maintaining single needle tufting machines to produce carpets. They adjust thread tension and stitch length to minimize fabric distortion and enhance product quality. They also collaborate with engineers to troubleshoot and resolve technical issues, implement preventative maintenance schedules, and develop training programs for new operators.

What skills are required to be a Single Needle Tufting Machine Operator?

Single Needle Tufting Machine Operators need to have a strong understanding of single needle tufting machines and be able to operate them efficiently. They also need to be able to adjust thread tension and stitch length, troubleshoot technical issues, and implement preventative maintenance schedules.

What is the work environment of a Single Needle Tufting Machine Operator?

Single Needle Tufting Machine Operators typically work in manufacturing plants. They work in a team environment and may be required to work overtime or on weekends.

What is the career outlook for Single Needle Tufting Machine Operators?

The career outlook for Single Needle Tufting Machine Operators is expected to be good. The demand for carpets is expected to grow in the coming years, which will lead to increased demand for Single Needle Tufting Machine Operators.

What is the average salary for a Single Needle Tufting Machine Operator?

The average salary for a Single Needle Tufting Machine Operator is $35,000 per year.

What are the benefits of being a Single Needle Tufting Machine Operator?

Benefits of being a Single Needle Tufting Machine Operator include a steady income, opportunities for advancement, and a sense of accomplishment.

What are the challenges of being a Single Needle Tufting Machine Operator?

Challenges of being a Single Needle Tufting Machine Operator include working in a noisy environment, working overtime or on weekends, and the risk of injury.

What advice would you give to someone who wants to become a Single Needle Tufting Machine Operator?

If you want to become a Single Needle Tufting Machine Operator, I recommend that you get training from a vocational school or community college. You can also learn on the job by working as a helper or apprentice.