Are you a seasoned Sinter Press Operator seeking a new career path? Discover our professionally built Sinter Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

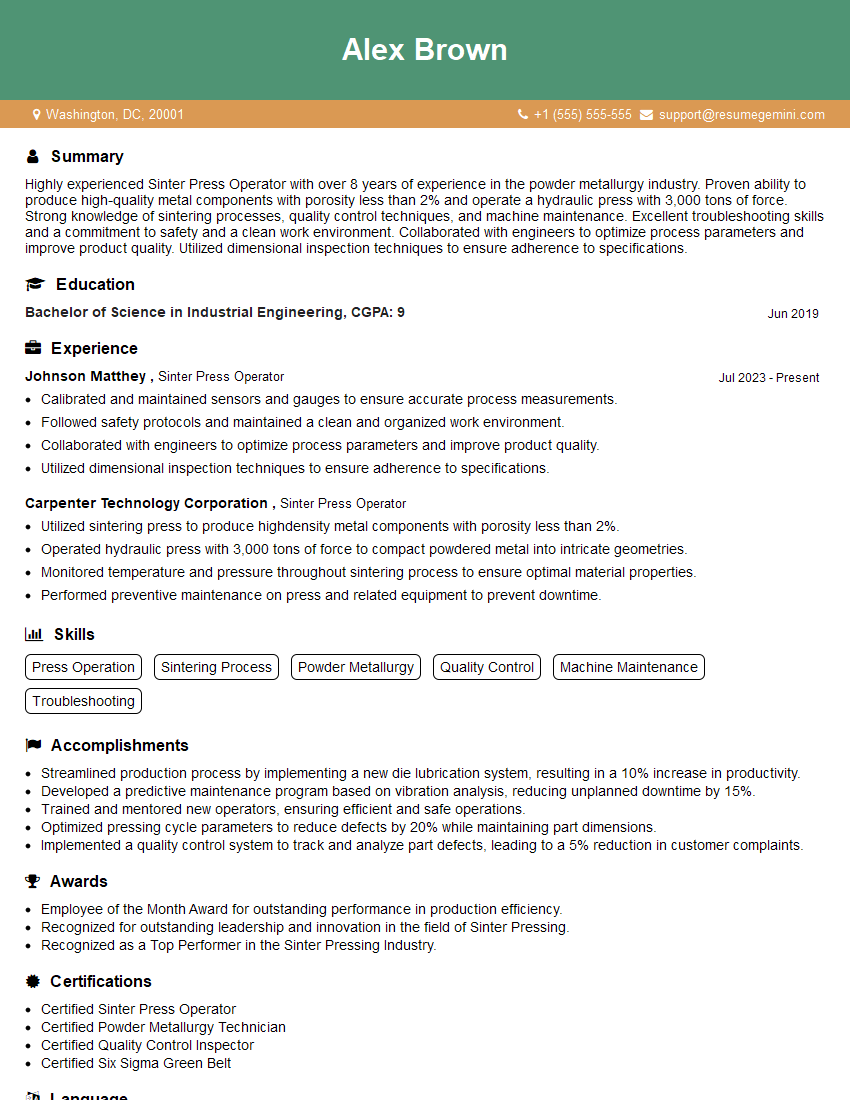

Alex Brown

Sinter Press Operator

Summary

Highly experienced Sinter Press Operator with over 8 years of experience in the powder metallurgy industry. Proven ability to produce high-quality metal components with porosity less than 2% and operate a hydraulic press with 3,000 tons of force. Strong knowledge of sintering processes, quality control techniques, and machine maintenance. Excellent troubleshooting skills and a commitment to safety and a clean work environment. Collaborated with engineers to optimize process parameters and improve product quality. Utilized dimensional inspection techniques to ensure adherence to specifications.

Education

Bachelor of Science in Industrial Engineering

June 2019

Skills

- Press Operation

- Sintering Process

- Powder Metallurgy

- Quality Control

- Machine Maintenance

- Troubleshooting

Work Experience

Sinter Press Operator

- Calibrated and maintained sensors and gauges to ensure accurate process measurements.

- Followed safety protocols and maintained a clean and organized work environment.

- Collaborated with engineers to optimize process parameters and improve product quality.

- Utilized dimensional inspection techniques to ensure adherence to specifications.

Sinter Press Operator

- Utilized sintering press to produce highdensity metal components with porosity less than 2%.

- Operated hydraulic press with 3,000 tons of force to compact powdered metal into intricate geometries.

- Monitored temperature and pressure throughout sintering process to ensure optimal material properties.

- Performed preventive maintenance on press and related equipment to prevent downtime.

Accomplishments

- Streamlined production process by implementing a new die lubrication system, resulting in a 10% increase in productivity.

- Developed a predictive maintenance program based on vibration analysis, reducing unplanned downtime by 15%.

- Trained and mentored new operators, ensuring efficient and safe operations.

- Optimized pressing cycle parameters to reduce defects by 20% while maintaining part dimensions.

- Implemented a quality control system to track and analyze part defects, leading to a 5% reduction in customer complaints.

Awards

- Employee of the Month Award for outstanding performance in production efficiency.

- Recognized for outstanding leadership and innovation in the field of Sinter Pressing.

- Recognized as a Top Performer in the Sinter Pressing Industry.

Certificates

- Certified Sinter Press Operator

- Certified Powder Metallurgy Technician

- Certified Quality Control Inspector

- Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sinter Press Operator

- Highlight your experience with sintering press operation and powder metallurgy.

- Showcase your knowledge of quality control techniques and machine maintenance.

- Emphasize your ability to troubleshoot and resolve production issues.

- Provide specific examples of your contributions to process optimization and product quality improvement.

Essential Experience Highlights for a Strong Sinter Press Operator Resume

- Operated sintering press to produce high-density metal components with porosity less than 2%.

- Monitored temperature and pressure throughout sintering process to ensure optimal material properties.

- Performed preventive maintenance on press and related equipment to prevent downtime.

- Calibrated and maintained sensors and gauges to ensure accurate process measurements.

- Followed safety protocols and maintained a clean and organized work environment.

- Collaborated with engineers to optimize process parameters and improve product quality.

Frequently Asked Questions (FAQ’s) For Sinter Press Operator

What is the primary function of a Sinter Press Operator?

The primary function of a Sinter Press Operator is to operate a sintering press to produce high-density metal components with porosity less than 2%.

What is the difference between sintering and forging?

Sintering is a powder metallurgy process that uses heat to bond metal particles without melting them, while forging is a metalworking process that uses pressure to shape metal.

What are the key skills required for a Sinter Press Operator?

Key skills for a Sinter Press Operator include press operation, sintering process knowledge, powder metallurgy understanding, quality control techniques, and machine maintenance skills.

What are the career prospects for a Sinter Press Operator?

Sinter Press Operators can advance to positions such as Quality Control Inspector, Production Supervisor, or Process Engineer.

What is the average salary for a Sinter Press Operator?

The average salary for a Sinter Press Operator varies depending on experience, location, and industry, but is typically around $50,000 per year.

What are the common challenges faced by a Sinter Press Operator?

Common challenges faced by a Sinter Press Operator include maintaining consistent product quality, preventing downtime, and troubleshooting production issues.