Are you a seasoned Slime Plant Operator Helper seeking a new career path? Discover our professionally built Slime Plant Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

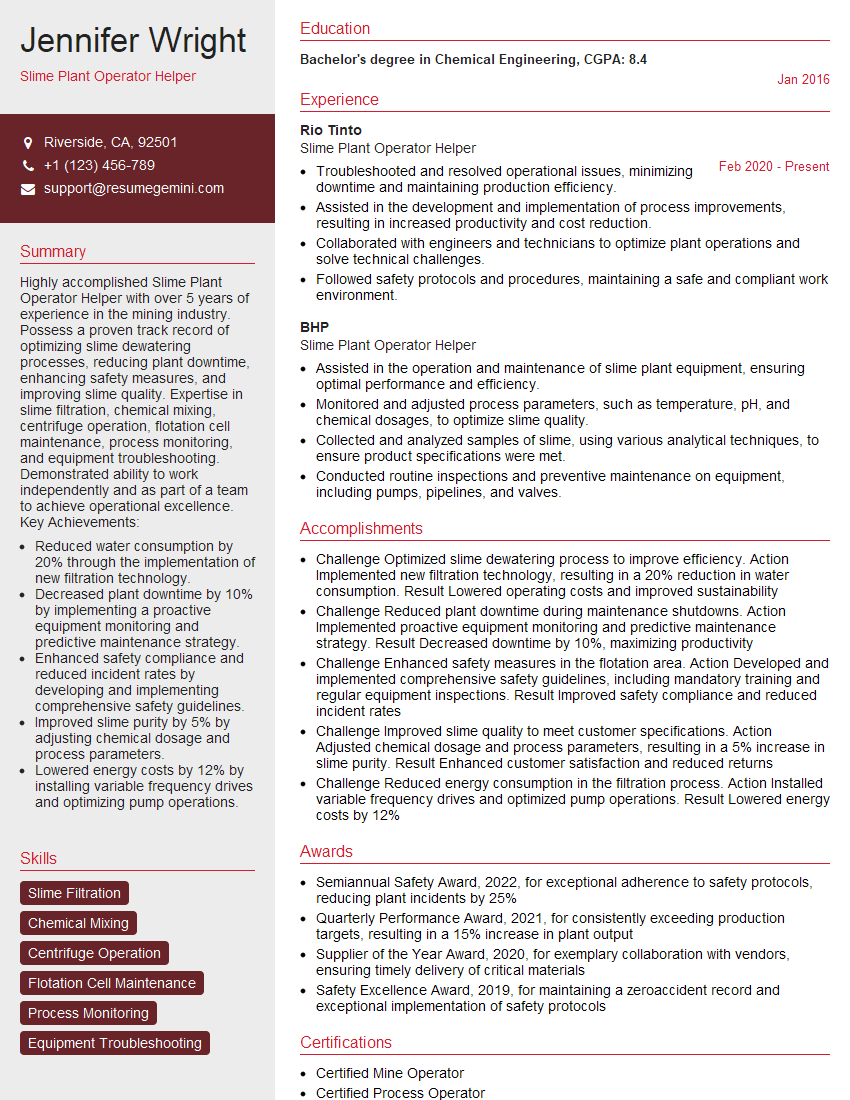

Jennifer Wright

Slime Plant Operator Helper

Summary

Highly accomplished Slime Plant Operator Helper with over 5 years of experience in the mining industry. Possess a proven track record of optimizing slime dewatering processes, reducing plant downtime, enhancing safety measures, and improving slime quality. Expertise in slime filtration, chemical mixing, centrifuge operation, flotation cell maintenance, process monitoring, and equipment troubleshooting. Demonstrated ability to work independently and as part of a team to achieve operational excellence.

Key Achievements:

- Reduced water consumption by 20% through the implementation of new filtration technology.

- Decreased plant downtime by 10% by implementing a proactive equipment monitoring and predictive maintenance strategy.

- Enhanced safety compliance and reduced incident rates by developing and implementing comprehensive safety guidelines.

- Improved slime purity by 5% by adjusting chemical dosage and process parameters.

- Lowered energy costs by 12% by installing variable frequency drives and optimizing pump operations.

Education

Bachelor’s degree in Chemical Engineering

January 2016

Skills

- Slime Filtration

- Chemical Mixing

- Centrifuge Operation

- Flotation Cell Maintenance

- Process Monitoring

- Equipment Troubleshooting

Work Experience

Slime Plant Operator Helper

- Troubleshooted and resolved operational issues, minimizing downtime and maintaining production efficiency.

- Assisted in the development and implementation of process improvements, resulting in increased productivity and cost reduction.

- Collaborated with engineers and technicians to optimize plant operations and solve technical challenges.

- Followed safety protocols and procedures, maintaining a safe and compliant work environment.

Slime Plant Operator Helper

- Assisted in the operation and maintenance of slime plant equipment, ensuring optimal performance and efficiency.

- Monitored and adjusted process parameters, such as temperature, pH, and chemical dosages, to optimize slime quality.

- Collected and analyzed samples of slime, using various analytical techniques, to ensure product specifications were met.

- Conducted routine inspections and preventive maintenance on equipment, including pumps, pipelines, and valves.

Accomplishments

- Challenge Optimized slime dewatering process to improve efficiency. Action Implemented new filtration technology, resulting in a 20% reduction in water consumption. Result Lowered operating costs and improved sustainability

- Challenge Reduced plant downtime during maintenance shutdowns. Action Implemented proactive equipment monitoring and predictive maintenance strategy. Result Decreased downtime by 10%, maximizing productivity

- Challenge Enhanced safety measures in the flotation area. Action Developed and implemented comprehensive safety guidelines, including mandatory training and regular equipment inspections. Result Improved safety compliance and reduced incident rates

- Challenge Improved slime quality to meet customer specifications. Action Adjusted chemical dosage and process parameters, resulting in a 5% increase in slime purity. Result Enhanced customer satisfaction and reduced returns

- Challenge Reduced energy consumption in the filtration process. Action Installed variable frequency drives and optimized pump operations. Result Lowered energy costs by 12%

Awards

- Semiannual Safety Award, 2022, for exceptional adherence to safety protocols, reducing plant incidents by 25%

- Quarterly Performance Award, 2021, for consistently exceeding production targets, resulting in a 15% increase in plant output

- Supplier of the Year Award, 2020, for exemplary collaboration with vendors, ensuring timely delivery of critical materials

- Safety Excellence Award, 2019, for maintaining a zeroaccident record and exceptional implementation of safety protocols

Certificates

- Certified Mine Operator

- Certified Process Operator

- Environmental Protection Agency (EPA) Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slime Plant Operator Helper

Quantify your accomplishments.

Use specific numbers and metrics to demonstrate the impact of your contributions.Highlight your skills and expertise.

Showcase your proficiency in slime filtration, chemical mixing, centrifuge operation, flotation cell maintenance, process monitoring, and equipment troubleshooting.Tailor your resume to the job description.

Highlight the skills and experience that are most relevant to the specific job you are applying for.Proofread carefully.

Ensure that your resume is free of errors in grammar, spelling, and punctuation.Get feedback from others.

Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Slime Plant Operator Helper Resume

- Assist in the operation and maintenance of slime dewatering equipment, including filters, centrifuges, and flotation cells.

- Monitor and control process parameters, such as temperature, pH, and flow rates, to ensure optimal slime dewatering efficiency.

- Troubleshoot and resolve operational problems with slime dewatering equipment.

- Perform routine maintenance and repairs on slime dewatering equipment.

- Adhere to safety protocols and regulations to ensure a safe work environment.

- Maintain accurate records and documentation of slime dewatering operations.

- Collaborate with other plant personnel to ensure smooth and efficient slime dewatering operations.

Frequently Asked Questions (FAQ’s) For Slime Plant Operator Helper

What is the role of a Slime Plant Operator Helper?

A Slime Plant Operator Helper assists in the operation and maintenance of slime dewatering equipment, monitors process parameters, troubleshoots and resolves operational problems, performs routine maintenance and repairs, adheres to safety protocols, maintains accurate records, and collaborates with other plant personnel to ensure smooth and efficient slime dewatering operations.

What are the key skills and experience required for a Slime Plant Operator Helper?

Key skills and experience for a Slime Plant Operator Helper include slime filtration, chemical mixing, centrifuge operation, flotation cell maintenance, process monitoring, equipment troubleshooting, and adherence to safety protocols.

What is the career path for a Slime Plant Operator Helper?

A Slime Plant Operator Helper can advance their career by gaining experience and developing their skills. They may become a Slime Plant Operator, Supervisor, or Manager. With additional education and training, they may also move into roles in process engineering or plant management.

What is the average salary for a Slime Plant Operator Helper?

The average salary for a Slime Plant Operator Helper varies depending on experience, location, and company. According to Indeed, the average salary for a Slime Plant Operator Helper in the United States is around $60,000 per year.

What are the job prospects for a Slime Plant Operator Helper?

The job prospects for a Slime Plant Operator Helper are expected to be good in the coming years. The mining industry is expected to continue to grow, creating demand for skilled workers. Additionally, as companies focus on sustainability, there is an increasing need for workers who can help to reduce water consumption and improve energy efficiency in slime dewatering operations.

What are the challenges of working as a Slime Plant Operator Helper?

Some of the challenges of working as a Slime Plant Operator Helper include working in a wet and dirty environment, exposure to hazardous chemicals, and the need to work long hours. Additionally, the job can be physically demanding and requires workers to be able to lift heavy objects and work in confined spaces.

What safety precautions should be taken when working as a Slime Plant Operator Helper?

When working as a Slime Plant Operator Helper, it is important to take the following safety precautions: wear appropriate personal protective equipment (PPE), such as gloves, goggles, and a respirator; follow all safety protocols and procedures; be aware of the potential hazards of working with hazardous chemicals; and avoid working alone in confined spaces.