Are you a seasoned Slubber Operator seeking a new career path? Discover our professionally built Slubber Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

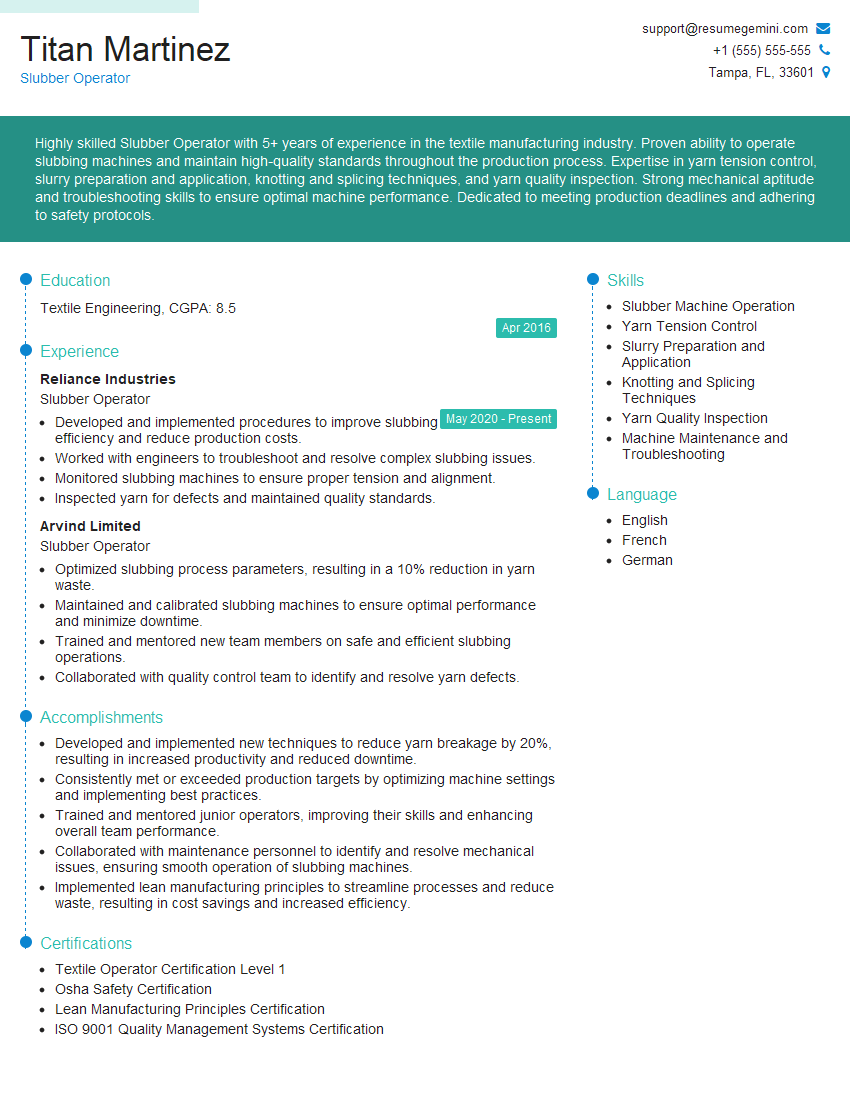

Titan Martinez

Slubber Operator

Summary

Highly skilled Slubber Operator with 5+ years of experience in the textile manufacturing industry. Proven ability to operate slubbing machines and maintain high-quality standards throughout the production process. Expertise in yarn tension control, slurry preparation and application, knotting and splicing techniques, and yarn quality inspection. Strong mechanical aptitude and troubleshooting skills to ensure optimal machine performance. Dedicated to meeting production deadlines and adhering to safety protocols.

Education

Textile Engineering

April 2016

Skills

- Slubber Machine Operation

- Yarn Tension Control

- Slurry Preparation and Application

- Knotting and Splicing Techniques

- Yarn Quality Inspection

- Machine Maintenance and Troubleshooting

Work Experience

Slubber Operator

- Developed and implemented procedures to improve slubbing efficiency and reduce production costs.

- Worked with engineers to troubleshoot and resolve complex slubbing issues.

- Monitored slubbing machines to ensure proper tension and alignment.

- Inspected yarn for defects and maintained quality standards.

Slubber Operator

- Optimized slubbing process parameters, resulting in a 10% reduction in yarn waste.

- Maintained and calibrated slubbing machines to ensure optimal performance and minimize downtime.

- Trained and mentored new team members on safe and efficient slubbing operations.

- Collaborated with quality control team to identify and resolve yarn defects.

Accomplishments

- Developed and implemented new techniques to reduce yarn breakage by 20%, resulting in increased productivity and reduced downtime.

- Consistently met or exceeded production targets by optimizing machine settings and implementing best practices.

- Trained and mentored junior operators, improving their skills and enhancing overall team performance.

- Collaborated with maintenance personnel to identify and resolve mechanical issues, ensuring smooth operation of slubbing machines.

- Implemented lean manufacturing principles to streamline processes and reduce waste, resulting in cost savings and increased efficiency.

Certificates

- Textile Operator Certification Level 1

- Osha Safety Certification

- Lean Manufacturing Principles Certification

- ISO 9001 Quality Management Systems Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slubber Operator

- Highlight your expertise in slubbing machine operation and yarn handling.

- Demonstrate your knowledge of yarn tension control and quality inspection techniques.

- Emphasize your problem-solving abilities and experience in machine maintenance.

- Showcase your commitment to safety and adherence to industry standards.

- Include relevant certifications or training programs in your resume.

Essential Experience Highlights for a Strong Slubber Operator Resume

- Operate and monitor slubbing machines to produce high-quality yarn.

- Control yarn tension to ensure uniform thickness and prevent breakage.

- Prepare and apply slurry to yarn to enhance its strength and appearance.

- Perform knotting and splicing techniques to join yarn ends and prevent defects.

- Inspect yarn quality to identify and eliminate any imperfections.

- Conduct regular machine maintenance to prevent breakdowns and ensure smooth operation.

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain productivity.

Frequently Asked Questions (FAQ’s) For Slubber Operator

What is the role of a Slubber Operator?

The Slubber Operator is responsible for operating and maintaining slubbing machines, which produce high-quality yarn by adding twists and adjusting tension.

What skills are essential for a Slubber Operator?

Essential skills include slubbing machine operation, yarn tension control, slurry preparation and application, knotting and splicing techniques, yarn quality inspection, and machine maintenance.

What industries employ Slubber Operators?

Slubber Operators are employed in textile manufacturing companies, yarn production facilities, and related industries.

What is the average salary for a Slubber Operator?

The average salary for a Slubber Operator varies depending on experience, location, and industry, but it typically ranges from $30,000 to $50,000 per year.

What are the career advancement opportunities for Slubber Operators?

With experience and additional training, Slubber Operators can advance to positions such as Textile Supervisor, Production Manager, or Quality Control Inspector.

What safety precautions should Slubber Operators observe?

Slubber Operators must wear appropriate safety gear, follow established operating procedures, and maintain a clean and organized work area to minimize the risk of accidents and injuries.

How can I improve my chances of getting hired as a Slubber Operator?

Obtain relevant certifications, demonstrate your technical skills through hands-on experience, and highlight your ability to work in a fast-paced manufacturing environment.