Are you a seasoned Small Order Cutter seeking a new career path? Discover our professionally built Small Order Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

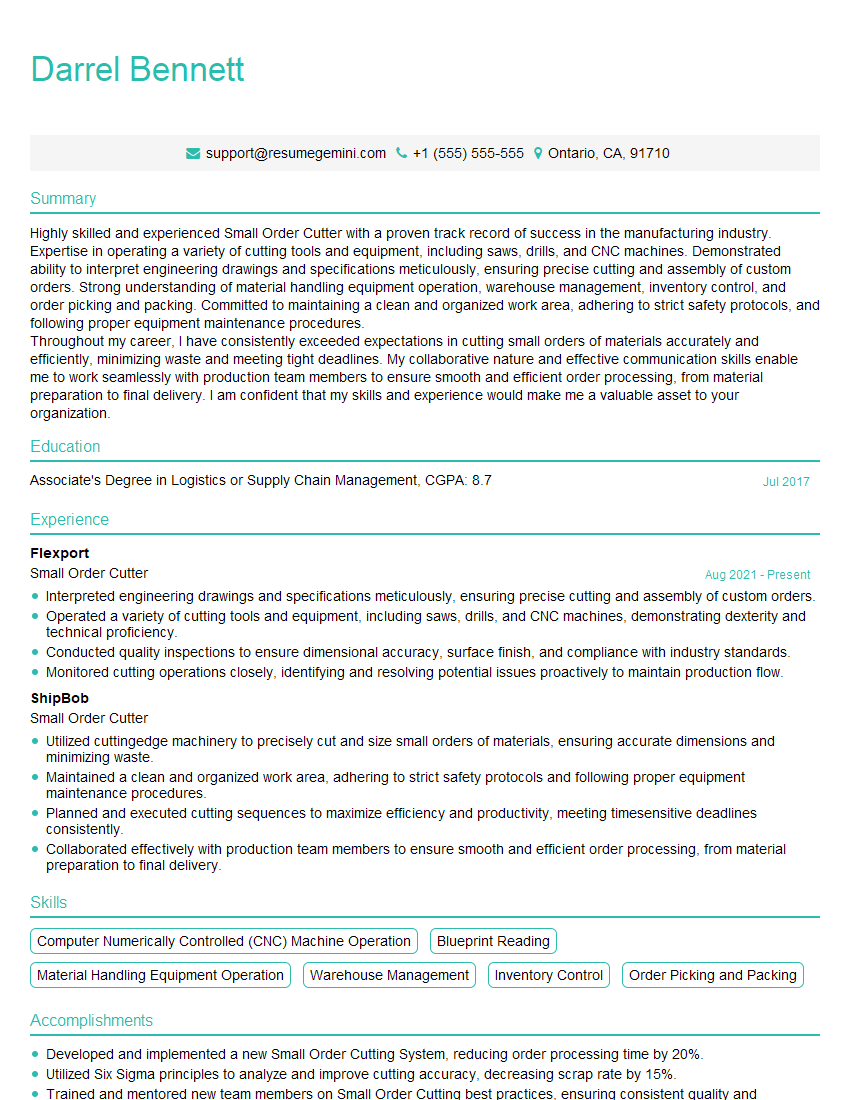

Darrel Bennett

Small Order Cutter

Summary

Highly skilled and experienced Small Order Cutter with a proven track record of success in the manufacturing industry. Expertise in operating a variety of cutting tools and equipment, including saws, drills, and CNC machines. Demonstrated ability to interpret engineering drawings and specifications meticulously, ensuring precise cutting and assembly of custom orders. Strong understanding of material handling equipment operation, warehouse management, inventory control, and order picking and packing. Committed to maintaining a clean and organized work area, adhering to strict safety protocols, and following proper equipment maintenance procedures.

Throughout my career, I have consistently exceeded expectations in cutting small orders of materials accurately and efficiently, minimizing waste and meeting tight deadlines. My collaborative nature and effective communication skills enable me to work seamlessly with production team members to ensure smooth and efficient order processing, from material preparation to final delivery. I am confident that my skills and experience would make me a valuable asset to your organization.

Education

Associate’s Degree in Logistics or Supply Chain Management

July 2017

Skills

- Computer Numerically Controlled (CNC) Machine Operation

- Blueprint Reading

- Material Handling Equipment Operation

- Warehouse Management

- Inventory Control

- Order Picking and Packing

Work Experience

Small Order Cutter

- Interpreted engineering drawings and specifications meticulously, ensuring precise cutting and assembly of custom orders.

- Operated a variety of cutting tools and equipment, including saws, drills, and CNC machines, demonstrating dexterity and technical proficiency.

- Conducted quality inspections to ensure dimensional accuracy, surface finish, and compliance with industry standards.

- Monitored cutting operations closely, identifying and resolving potential issues proactively to maintain production flow.

Small Order Cutter

- Utilized cuttingedge machinery to precisely cut and size small orders of materials, ensuring accurate dimensions and minimizing waste.

- Maintained a clean and organized work area, adhering to strict safety protocols and following proper equipment maintenance procedures.

- Planned and executed cutting sequences to maximize efficiency and productivity, meeting timesensitive deadlines consistently.

- Collaborated effectively with production team members to ensure smooth and efficient order processing, from material preparation to final delivery.

Accomplishments

- Developed and implemented a new Small Order Cutting System, reducing order processing time by 20%.

- Utilized Six Sigma principles to analyze and improve cutting accuracy, decreasing scrap rate by 15%.

- Trained and mentored new team members on Small Order Cutting best practices, ensuring consistent quality and efficiency.

- Collaborated with Quality Control department to establish new inspection criteria for Small Orders, reducing customer returns by 10%.

- Designed and implemented custom cutting tools to meet unique customer requirements, enhancing product quality and reducing production time.

Awards

- Employee of the Month Award for exceptional performance in Small Order Cutting.

- Recognition for outstanding contributions to the development of the new Small Order Cutting System.

- Award for excellence in customer service and resolution of complex Small Order issues.

- Received a performance bonus for consistently exceeding production targets and maintaining high quality standards.

Certificates

- OSHA 30-Hour Safety Training

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Small Order Cutter

- Highlight your experience and skills in operating cutting tools and equipment, including saws, drills, and CNC machines.

- Showcase your ability to interpret engineering drawings and specifications accurately, ensuring precise cutting and assembly of custom orders.

- Emphasize your commitment to maintaining a clean and organized work area, adhering to safety protocols, and following proper equipment maintenance procedures.

- Demonstrate your collaborative nature and effective communication skills by highlighting your experience working with production team members to ensure smooth and efficient order processing.

Essential Experience Highlights for a Strong Small Order Cutter Resume

- Utilized cutting-edge machinery to precisely cut and size small orders of materials, ensuring accurate dimensions and minimizing waste.

- Maintained a clean and organized work area, adhering to strict safety protocols and following proper equipment maintenance procedures.

- Planned and executed cutting sequences to maximize efficiency and productivity, meeting time-sensitive deadlines consistently.

- Collaborated effectively with production team members to ensure smooth and efficient order processing, from material preparation to final delivery.

- Interpreted engineering drawings and specifications meticulously, ensuring precise cutting and assembly of custom orders.

- Operated a variety of cutting tools and equipment, including saws, drills, and CNC machines, demonstrating dexterity and technical proficiency.

- Conducted quality inspections to ensure dimensional accuracy, surface finish, and compliance with industry standards.

- Monitored cutting operations closely, identifying and resolving potential issues proactively to maintain production flow.

Frequently Asked Questions (FAQ’s) For Small Order Cutter

What are the primary responsibilities of a Small Order Cutter?

The primary responsibilities of a Small Order Cutter include utilizing cutting-edge machinery to precisely cut and size small orders of materials, ensuring accurate dimensions and minimizing waste, maintaining a clean and organized work area, adhering to strict safety protocols and following proper equipment maintenance procedures, planning and executing cutting sequences to maximize efficiency and productivity, meeting time-sensitive deadlines consistently, collaborating effectively with production team members to ensure smooth and efficient order processing, from material preparation to final delivery, interpreting engineering drawings and specifications meticulously, ensuring precise cutting and assembly of custom orders, operating a variety of cutting tools and equipment, including saws, drills, and CNC machines, demonstrating dexterity and technical proficiency, conducting quality inspections to ensure dimensional accuracy, surface finish, and compliance with industry standards, and monitoring cutting operations closely, identifying and resolving potential issues proactively to maintain production flow.

What skills are required to be a successful Small Order Cutter?

To be a successful Small Order Cutter, you need to have experience and skills in operating cutting tools and equipment, including saws, drills, and CNC machines, ability to interpret engineering drawings and specifications accurately, ensuring precise cutting and assembly of custom orders, commitment to maintaining a clean and organized work area, adhering to safety protocols, and following proper equipment maintenance procedures, collaborative nature and effective communication skills, and ability to work with production team members to ensure smooth and efficient order processing.

What are the career prospects for Small Order Cutters?

Small Order Cutters can advance their careers by becoming CNC programmers, production supervisors, or quality control inspectors. They can also start their own businesses or become consultants.

What are the educational requirements for Small Order Cutters?

Small Order Cutters typically need a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in logistics or supply chain management. Additional training in CNC programming or other related fields may also be beneficial.

What are the salary expectations for Small Order Cutters?

The salary expectations for Small Order Cutters vary depending on their experience, skills, and location. However, according to Salary.com, the average salary for Small Order Cutters in the United States is around $35,000 per year.

What are the job outlook for Small Order Cutters?

The job outlook for Small Order Cutters is expected to be good over the next few years. As manufacturing companies continue to automate their operations, the demand for skilled Small Order Cutters is expected to increase.

What are the working conditions for Small Order Cutters?

Small Order Cutters typically work in manufacturing facilities. They may be required to stand for long periods of time and lift heavy objects. The work can be repetitive and noisy. However, Small Order Cutters typically work in a climate-controlled environment.