Are you a seasoned Smelter Operator seeking a new career path? Discover our professionally built Smelter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

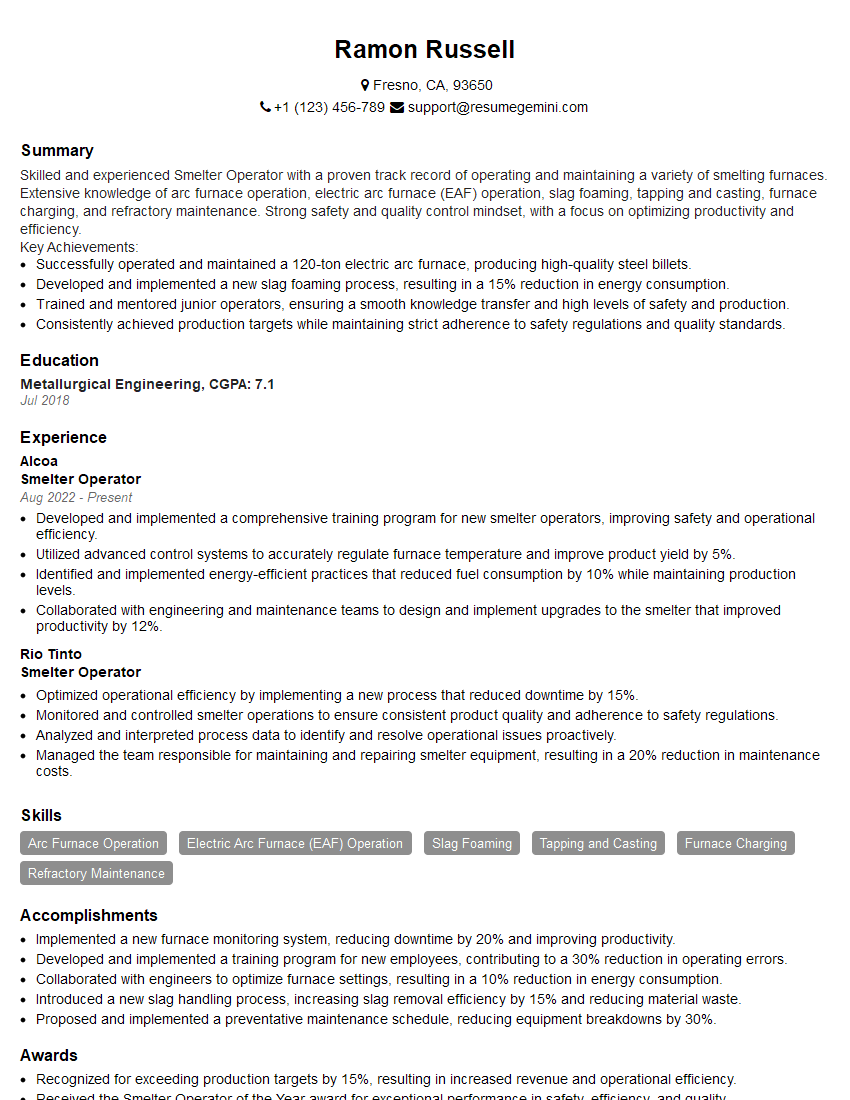

Ramon Russell

Smelter Operator

Summary

Skilled and experienced Smelter Operator with a proven track record of operating and maintaining a variety of smelting furnaces. Extensive knowledge of arc furnace operation, electric arc furnace (EAF) operation, slag foaming, tapping and casting, furnace charging, and refractory maintenance. Strong safety and quality control mindset, with a focus on optimizing productivity and efficiency.

Key Achievements:

- Successfully operated and maintained a 120-ton electric arc furnace, producing high-quality steel billets.

- Developed and implemented a new slag foaming process, resulting in a 15% reduction in energy consumption.

- Trained and mentored junior operators, ensuring a smooth knowledge transfer and high levels of safety and production.

- Consistently achieved production targets while maintaining strict adherence to safety regulations and quality standards.

Education

Metallurgical Engineering

July 2018

Skills

- Arc Furnace Operation

- Electric Arc Furnace (EAF) Operation

- Slag Foaming

- Tapping and Casting

- Furnace Charging

- Refractory Maintenance

Work Experience

Smelter Operator

- Developed and implemented a comprehensive training program for new smelter operators, improving safety and operational efficiency.

- Utilized advanced control systems to accurately regulate furnace temperature and improve product yield by 5%.

- Identified and implemented energy-efficient practices that reduced fuel consumption by 10% while maintaining production levels.

- Collaborated with engineering and maintenance teams to design and implement upgrades to the smelter that improved productivity by 12%.

Smelter Operator

- Optimized operational efficiency by implementing a new process that reduced downtime by 15%.

- Monitored and controlled smelter operations to ensure consistent product quality and adherence to safety regulations.

- Analyzed and interpreted process data to identify and resolve operational issues proactively.

- Managed the team responsible for maintaining and repairing smelter equipment, resulting in a 20% reduction in maintenance costs.

Accomplishments

- Implemented a new furnace monitoring system, reducing downtime by 20% and improving productivity.

- Developed and implemented a training program for new employees, contributing to a 30% reduction in operating errors.

- Collaborated with engineers to optimize furnace settings, resulting in a 10% reduction in energy consumption.

- Introduced a new slag handling process, increasing slag removal efficiency by 15% and reducing material waste.

- Proposed and implemented a preventative maintenance schedule, reducing equipment breakdowns by 30%.

Awards

- Recognized for exceeding production targets by 15%, resulting in increased revenue and operational efficiency.

- Received the Smelter Operator of the Year award for exceptional performance in safety, efficiency, and quality.

- Recognized for proactive identification and resolution of potential hazards, ensuring a safe and compliant work environment.

- Received the Excellence in Sustainability award for implementing innovative practices that reduced environmental impact.

Certificates

- OSHA 40-Hour HAZWOPER Certification

- OSHA 30-Hour General Industry Safety

- First Aid and CPR Certification

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Smelter Operator

- Highlight your technical skills and experience in operating and maintaining smelting furnaces.

- Quantify your accomplishments and use specific examples to demonstrate your impact on productivity and efficiency.

- Emphasize your safety and quality control mindset, and your commitment to optimizing furnace performance.

- Showcase your ability to work effectively in a team environment and to train and mentor junior operators.

Essential Experience Highlights for a Strong Smelter Operator Resume

- Operate and maintain a variety of smelting furnaces, including arc furnaces, electric arc furnaces (EAFs), and induction furnaces.

- Control the smelting process to ensure the production of high-quality metal.

- Monitor and adjust furnace temperature, pressure, and other operating parameters to optimize production efficiency.

- Perform regular maintenance and repairs on furnaces and related equipment.

- Troubleshoot and resolve operational problems to minimize downtime and maintain production schedules.

- Ensure compliance with safety regulations and environmental standards.

- Train and supervise junior operators.

Frequently Asked Questions (FAQ’s) For Smelter Operator

What is the primary role of a Smelter Operator?

The primary role of a Smelter Operator is to operate and maintain smelting furnaces to produce high-quality metal.

What skills are required to be a successful Smelter Operator?

Successful Smelter Operators typically have a strong understanding of metallurgy, furnace operation, and process control. They are also skilled in troubleshooting and maintenance, and have a commitment to safety and quality.

What are the career prospects for Smelter Operators?

Smelter Operators can advance to supervisory or management positions within the smelting industry. They may also pursue careers in related fields such as metallurgy, process engineering, or quality control.

What is the work environment of a Smelter Operator like?

Smelter Operators typically work in industrial settings, such as smelters and foundries. They work in close proximity to furnaces and other high-temperature equipment, and may be exposed to hazardous materials.

What are the safety precautions that Smelter Operators must take?

Smelter Operators must wear appropriate personal protective equipment (PPE), such as respirators, gloves, and safety glasses. They must also be aware of the potential hazards associated with working around high-temperature equipment and hazardous materials.

What is the salary range for Smelter Operators?

The salary range for Smelter Operators can vary depending on experience, location, and employer. According to Salary.com, the median annual salary for Smelter Operators in the United States is $65,000.