Are you a seasoned Smelter seeking a new career path? Discover our professionally built Smelter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

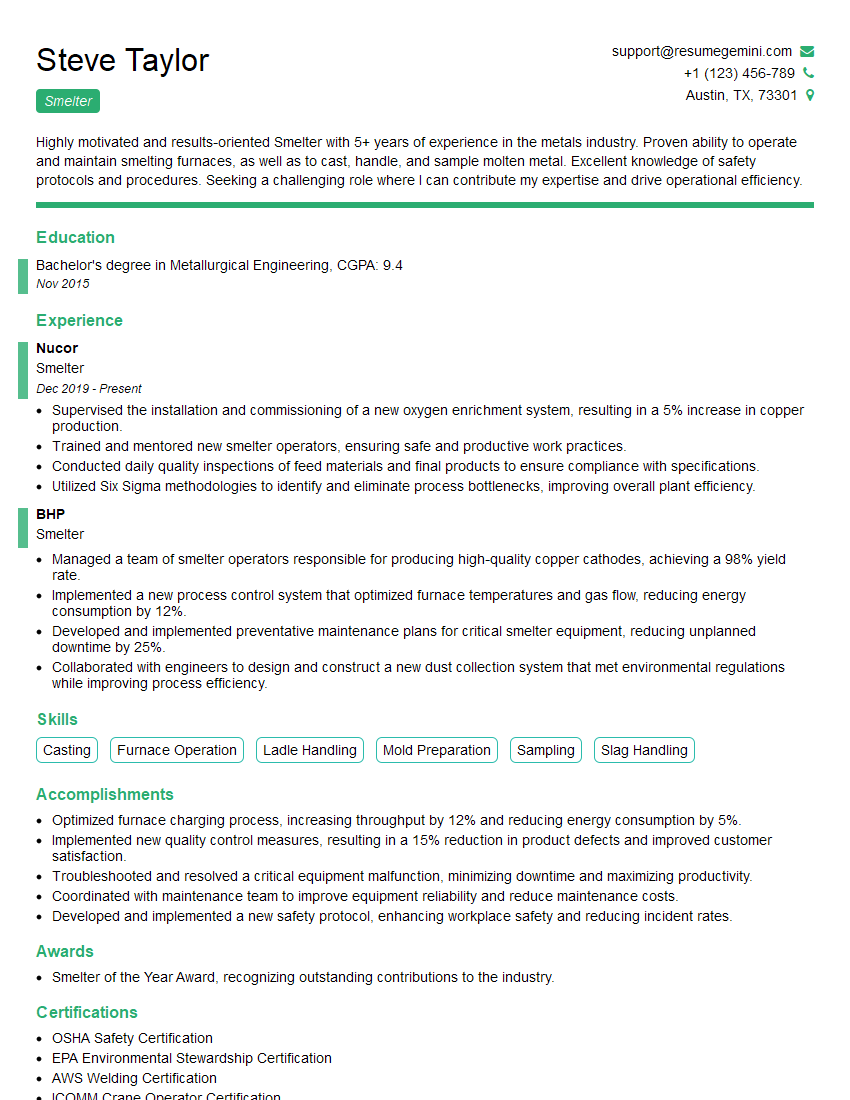

Steve Taylor

Smelter

Summary

Highly motivated and results-oriented Smelter with 5+ years of experience in the metals industry. Proven ability to operate and maintain smelting furnaces, as well as to cast, handle, and sample molten metal. Excellent knowledge of safety protocols and procedures. Seeking a challenging role where I can contribute my expertise and drive operational efficiency.

Education

Bachelor’s degree in Metallurgical Engineering

November 2015

Skills

- Casting

- Furnace Operation

- Ladle Handling

- Mold Preparation

- Sampling

- Slag Handling

Work Experience

Smelter

- Supervised the installation and commissioning of a new oxygen enrichment system, resulting in a 5% increase in copper production.

- Trained and mentored new smelter operators, ensuring safe and productive work practices.

- Conducted daily quality inspections of feed materials and final products to ensure compliance with specifications.

- Utilized Six Sigma methodologies to identify and eliminate process bottlenecks, improving overall plant efficiency.

Smelter

- Managed a team of smelter operators responsible for producing high-quality copper cathodes, achieving a 98% yield rate.

- Implemented a new process control system that optimized furnace temperatures and gas flow, reducing energy consumption by 12%.

- Developed and implemented preventative maintenance plans for critical smelter equipment, reducing unplanned downtime by 25%.

- Collaborated with engineers to design and construct a new dust collection system that met environmental regulations while improving process efficiency.

Accomplishments

- Optimized furnace charging process, increasing throughput by 12% and reducing energy consumption by 5%.

- Implemented new quality control measures, resulting in a 15% reduction in product defects and improved customer satisfaction.

- Troubleshooted and resolved a critical equipment malfunction, minimizing downtime and maximizing productivity.

- Coordinated with maintenance team to improve equipment reliability and reduce maintenance costs.

- Developed and implemented a new safety protocol, enhancing workplace safety and reducing incident rates.

Awards

- Smelter of the Year Award, recognizing outstanding contributions to the industry.

Certificates

- OSHA Safety Certification

- EPA Environmental Stewardship Certification

- AWS Welding Certification

- ICOMM Crane Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Smelter

- Highlight your experience and skills in operating and maintaining smelting furnaces.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Smelter Resume

- Operate and maintain smelting furnaces to produce molten metal according to specifications.

- Cast molten metal into molds and handle ladles safely and efficiently.

- Prepare molds for casting and ensure they meet quality standards.

- Sample molten metal to analyze its composition and ensure it meets specifications.

- Handle and dispose of slag safely and efficiently.

- Monitor and maintain equipment to ensure optimal performance and prevent breakdowns.

- Adhere to all safety protocols and procedures to ensure a safe working environment.

Frequently Asked Questions (FAQ’s) For Smelter

What is the role of a Smelter?

A Smelter is responsible for operating and maintaining smelting furnaces, casting molten metal, and handling ladles. They also prepare molds for casting, sample molten metal, and handle and dispose of slag.

What are the qualifications for becoming a Smelter?

Most Smelters have a high school diploma or equivalent, as well as some experience working in a metalworking or manufacturing environment. Some employers may prefer candidates with a post-secondary degree in metallurgy or a related field.

What are the job prospects for Smelters?

The job outlook for Smelters is expected to be good over the next few years. The demand for smelted metals is expected to increase as the global economy continues to grow. However, competition for jobs may be strong, so it is important to have a strong resume and interview skills.

What is the average salary for a Smelter?

The average salary for a Smelter in the United States is around $55,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the benefits of working as a Smelter?

Smelters can enjoy a number of benefits, including a competitive salary, health insurance, paid time off, and a retirement plan. Smelters also have the opportunity to work in a challenging and rewarding environment.