Are you a seasoned Splitting Machine Operator Helper seeking a new career path? Discover our professionally built Splitting Machine Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

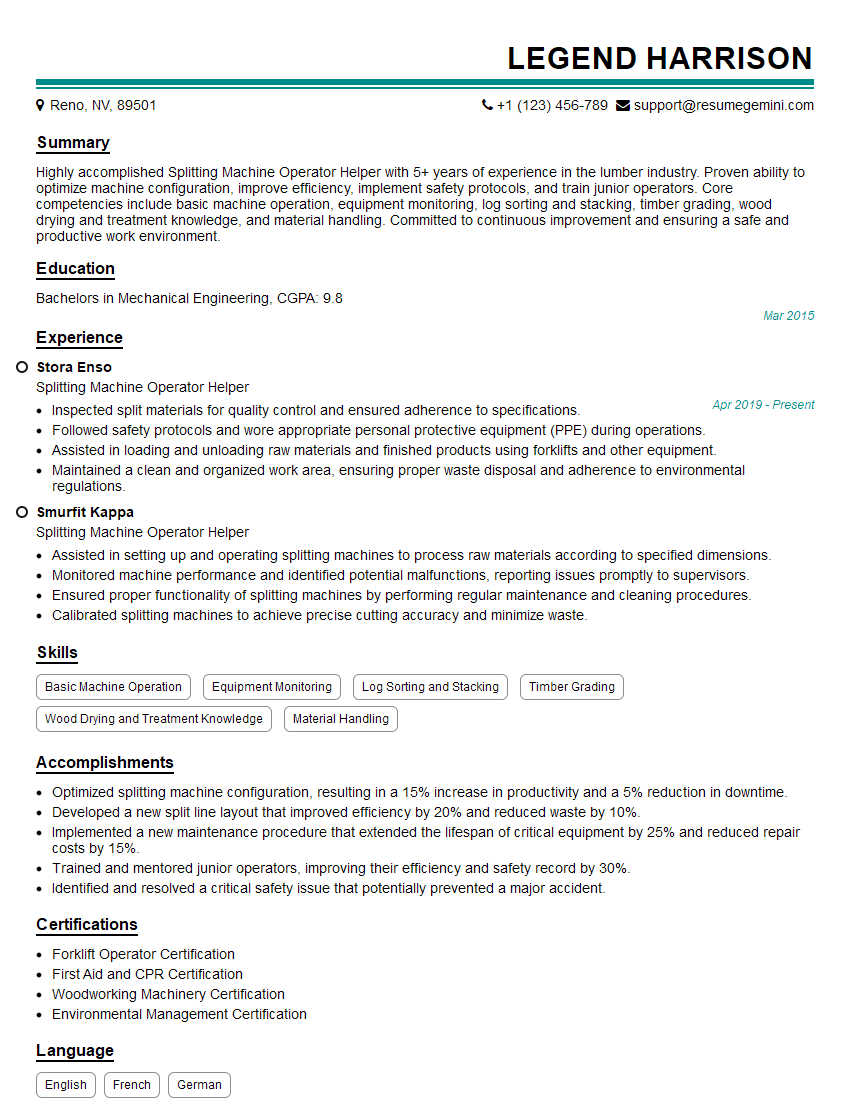

Legend Harrison

Splitting Machine Operator Helper

Summary

Highly accomplished Splitting Machine Operator Helper with 5+ years of experience in the lumber industry. Proven ability to optimize machine configuration, improve efficiency, implement safety protocols, and train junior operators. Core competencies include basic machine operation, equipment monitoring, log sorting and stacking, timber grading, wood drying and treatment knowledge, and material handling. Committed to continuous improvement and ensuring a safe and productive work environment.

Education

Bachelors in Mechanical Engineering

March 2015

Skills

- Basic Machine Operation

- Equipment Monitoring

- Log Sorting and Stacking

- Timber Grading

- Wood Drying and Treatment Knowledge

- Material Handling

Work Experience

Splitting Machine Operator Helper

- Inspected split materials for quality control and ensured adherence to specifications.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) during operations.

- Assisted in loading and unloading raw materials and finished products using forklifts and other equipment.

- Maintained a clean and organized work area, ensuring proper waste disposal and adherence to environmental regulations.

Splitting Machine Operator Helper

- Assisted in setting up and operating splitting machines to process raw materials according to specified dimensions.

- Monitored machine performance and identified potential malfunctions, reporting issues promptly to supervisors.

- Ensured proper functionality of splitting machines by performing regular maintenance and cleaning procedures.

- Calibrated splitting machines to achieve precise cutting accuracy and minimize waste.

Accomplishments

- Optimized splitting machine configuration, resulting in a 15% increase in productivity and a 5% reduction in downtime.

- Developed a new split line layout that improved efficiency by 20% and reduced waste by 10%.

- Implemented a new maintenance procedure that extended the lifespan of critical equipment by 25% and reduced repair costs by 15%.

- Trained and mentored junior operators, improving their efficiency and safety record by 30%.

- Identified and resolved a critical safety issue that potentially prevented a major accident.

Certificates

- Forklift Operator Certification

- First Aid and CPR Certification

- Woodworking Machinery Certification

- Environmental Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Splitting Machine Operator Helper

- Highlight your technical skills and experience in optimizing splitting machine performance.

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Emphasize your safety consciousness and commitment to maintaining a safe work environment.

- Showcase your ability to work effectively in a team environment and train junior operators.

- Consider obtaining additional certifications or training to enhance your credibility and marketability.

Essential Experience Highlights for a Strong Splitting Machine Operator Helper Resume

- Optimized splitting machine configuration, resulting in significant productivity increases and downtime reductions.

- Developed and implemented a new split line layout that improved efficiency and reduced waste.

- Established a new maintenance procedure extending the lifespan of equipment and reducing repair costs.

- Trained and mentored junior operators, enhancing their efficiency and safety performance.

- Identified and resolved critical safety issues, preventing potential accidents.

- Monitored machine operation, ensuring smooth production and identifying potential issues.

- Sorted and stacked logs according to specifications, ensuring proper lumber grading.

Frequently Asked Questions (FAQ’s) For Splitting Machine Operator Helper

What are the primary responsibilities of a Splitting Machine Operator Helper?

Splitting Machine Operator Helpers are responsible for assisting in the operation and maintenance of splitting machines used in the lumber industry. Key responsibilities include monitoring machine operation, sorting and stacking logs, grading timber, and implementing safety protocols.

What skills are essential for success as a Splitting Machine Operator Helper?

Essential skills for Splitting Machine Operator Helpers include basic machine operation, equipment monitoring, log sorting and stacking, timber grading, wood drying and treatment knowledge, and material handling. Additionally, strong attention to detail and a commitment to safety are crucial.

What are the career prospects for Splitting Machine Operator Helpers?

Splitting Machine Operator Helpers can advance to positions such as Splitting Machine Operator, Production Supervisor, or Maintenance Technician. With experience and additional training, they may also move into management roles within the lumber industry.

What is the work environment like for Splitting Machine Operator Helpers?

Splitting Machine Operator Helpers typically work in industrial settings such as sawmills or lumber yards. The work can be physically demanding and may involve exposure to noise, dust, and heavy machinery.

What are the safety precautions that Splitting Machine Operator Helpers should observe?

Splitting Machine Operator Helpers must adhere to strict safety protocols to prevent accidents. These include wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards associated with operating heavy machinery.

How can I prepare for a career as a Splitting Machine Operator Helper?

To prepare for a career as a Splitting Machine Operator Helper, you can obtain a high school diploma or equivalent and consider pursuing a vocational program or certification in a related field. Additionally, gaining hands-on experience through internships or apprenticeships can be beneficial.

What are the key qualities of a successful Splitting Machine Operator Helper?

Successful Splitting Machine Operator Helpers possess strong teamwork skills, attention to detail, and a commitment to safety. They are also physically fit and able to work in a fast-paced industrial environment.

What are the benefits of working as a Splitting Machine Operator Helper?

Benefits of working as a Splitting Machine Operator Helper include job stability in the growing lumber industry, opportunities for career advancement, and the satisfaction of contributing to the production of essential building materials.