Are you a seasoned Spot Man seeking a new career path? Discover our professionally built Spot Man Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

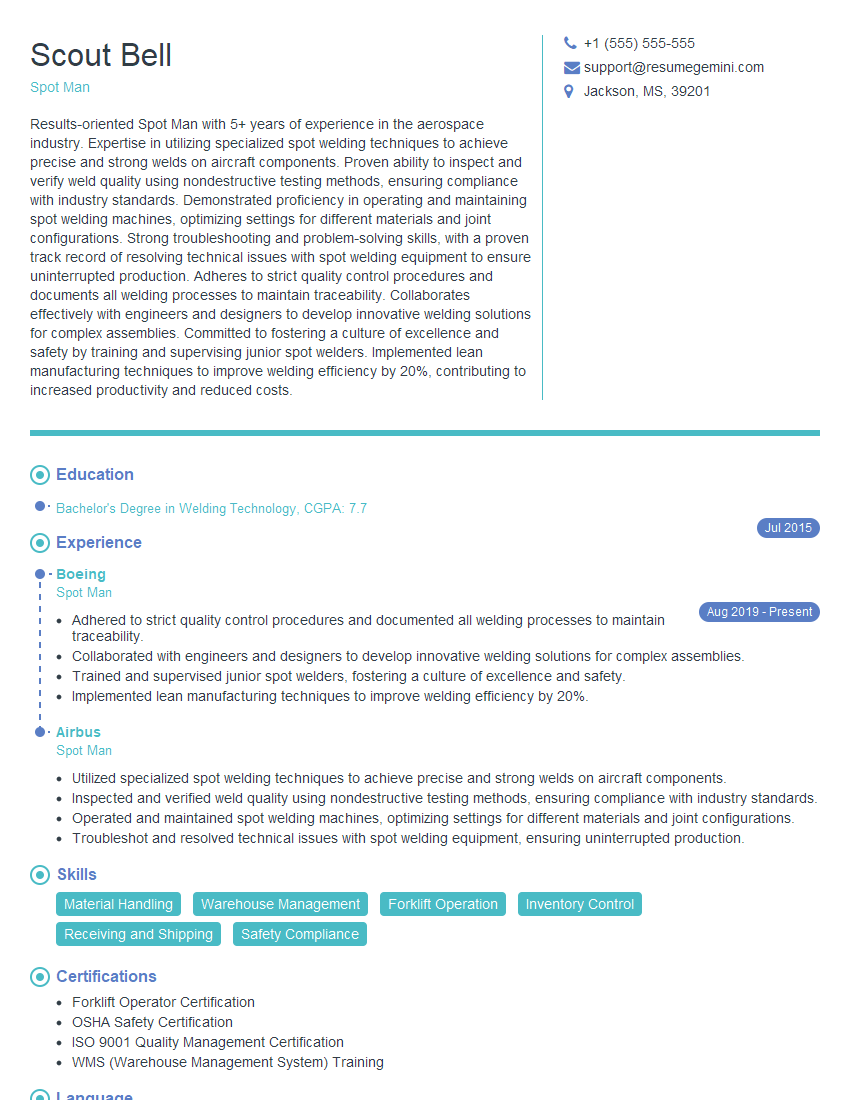

Scout Bell

Spot Man

Summary

Results-oriented Spot Man with 5+ years of experience in the aerospace industry. Expertise in utilizing specialized spot welding techniques to achieve precise and strong welds on aircraft components. Proven ability to inspect and verify weld quality using nondestructive testing methods, ensuring compliance with industry standards. Demonstrated proficiency in operating and maintaining spot welding machines, optimizing settings for different materials and joint configurations. Strong troubleshooting and problem-solving skills, with a proven track record of resolving technical issues with spot welding equipment to ensure uninterrupted production. Adheres to strict quality control procedures and documents all welding processes to maintain traceability. Collaborates effectively with engineers and designers to develop innovative welding solutions for complex assemblies. Committed to fostering a culture of excellence and safety by training and supervising junior spot welders. Implemented lean manufacturing techniques to improve welding efficiency by 20%, contributing to increased productivity and reduced costs.

Education

Bachelor’s Degree in Welding Technology

July 2015

Skills

- Material Handling

- Warehouse Management

- Forklift Operation

- Inventory Control

- Receiving and Shipping

- Safety Compliance

Work Experience

Spot Man

- Adhered to strict quality control procedures and documented all welding processes to maintain traceability.

- Collaborated with engineers and designers to develop innovative welding solutions for complex assemblies.

- Trained and supervised junior spot welders, fostering a culture of excellence and safety.

- Implemented lean manufacturing techniques to improve welding efficiency by 20%.

Spot Man

- Utilized specialized spot welding techniques to achieve precise and strong welds on aircraft components.

- Inspected and verified weld quality using nondestructive testing methods, ensuring compliance with industry standards.

- Operated and maintained spot welding machines, optimizing settings for different materials and joint configurations.

- Troubleshot and resolved technical issues with spot welding equipment, ensuring uninterrupted production.

Certificates

- Forklift Operator Certification

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- WMS (Warehouse Management System) Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Spot Man

- Highlight your expertise in specialized spot welding techniques and proficiency in operating and maintaining spot welding machines.

- Quantify your accomplishments, such as the 20% improvement in welding efficiency you achieved through implementing lean manufacturing techniques.

- Emphasize your commitment to quality by mentioning your adherence to strict quality control procedures and use of nondestructive testing methods to verify weld quality.

- Showcase your collaborative spirit and problem-solving abilities by describing your contributions to developing innovative welding solutions and troubleshooting technical issues.

Essential Experience Highlights for a Strong Spot Man Resume

- Utilize specialized spot welding techniques to achieve precise and strong welds on aircraft components.

- Inspect and verify weld quality using nondestructive testing methods, ensuring compliance with industry standards.

- Operate and maintain spot welding machines, optimizing settings for different materials and joint configurations.

- Troubleshoot and resolve technical issues with spot welding equipment, ensuring uninterrupted production.

- Adhere to strict quality control procedures and document all welding processes to maintain traceability.

- Collaborate with engineers and designers to develop innovative welding solutions for complex assemblies.

- Train and supervise junior spot welders, fostering a culture of excellence and safety.

Frequently Asked Questions (FAQ’s) For Spot Man

What is the primary role of a Spot Man?

The primary role of a Spot Man is to utilize specialized spot welding techniques to achieve precise and strong welds on aircraft components.

What key skills are required for a Spot Man?

Key skills for a Spot Man include expertise in spot welding techniques, proficiency in operating and maintaining spot welding machines, and the ability to inspect and verify weld quality using nondestructive testing methods.

What industries commonly employ Spot Men?

Spot Men are commonly employed in the aerospace, automotive, and manufacturing industries.

What are the career advancement opportunities for a Spot Man?

Career advancement opportunities for a Spot Man include promotions to Lead Spot Man, Welding Supervisor, or Quality Control Manager.

What is the average salary range for a Spot Man?

The average salary range for a Spot Man in the United States is between $40,000 and $60,000.

What are the educational requirements to become a Spot Man?

Most Spot Men have a high school diploma or equivalent and receive on-the-job training. Some employers may prefer candidates with a Bachelor’s Degree in Welding Technology or a related field.

What are the safety precautions that a Spot Man must follow?

Spot Men must follow strict safety precautions, including wearing appropriate protective gear, ensuring proper ventilation, and adhering to established welding safety protocols.