Are you a seasoned Spot Welder seeking a new career path? Discover our professionally built Spot Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

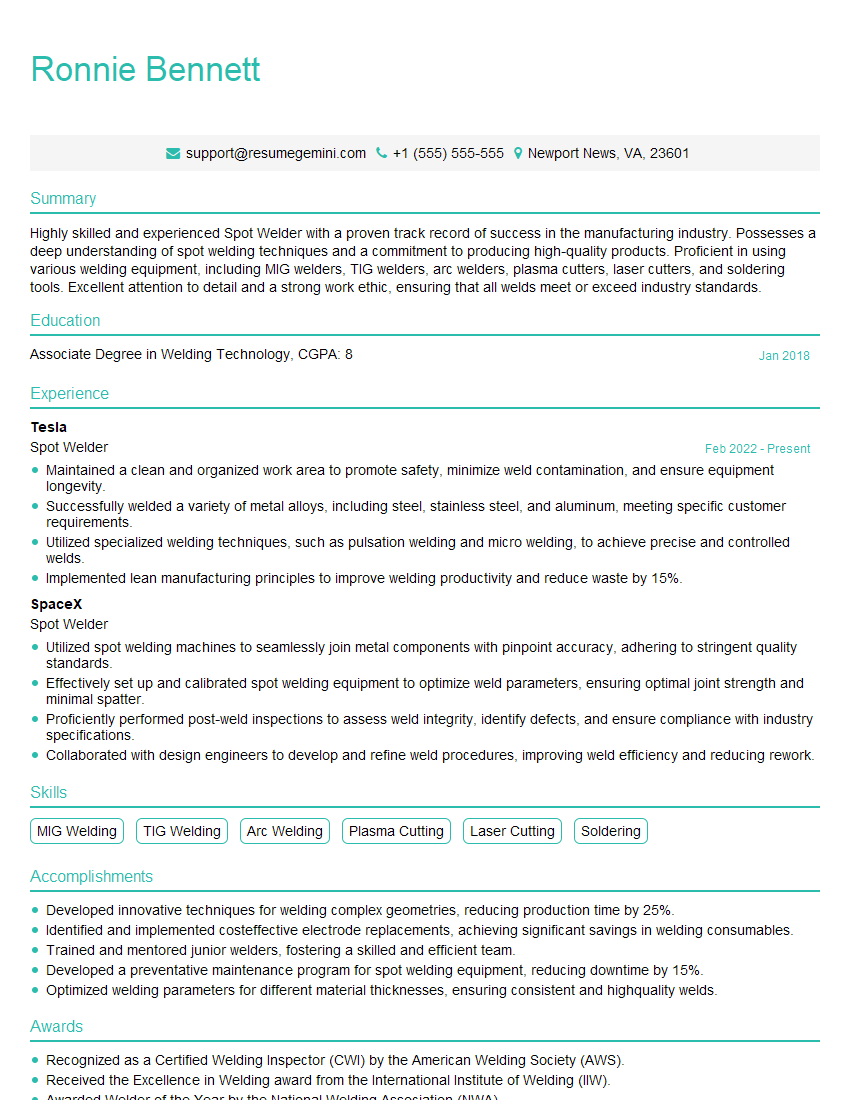

Ronnie Bennett

Spot Welder

Summary

Highly skilled and experienced Spot Welder with a proven track record of success in the manufacturing industry. Possesses a deep understanding of spot welding techniques and a commitment to producing high-quality products. Proficient in using various welding equipment, including MIG welders, TIG welders, arc welders, plasma cutters, laser cutters, and soldering tools. Excellent attention to detail and a strong work ethic, ensuring that all welds meet or exceed industry standards.

Education

Associate Degree in Welding Technology

January 2018

Skills

- MIG Welding

- TIG Welding

- Arc Welding

- Plasma Cutting

- Laser Cutting

- Soldering

Work Experience

Spot Welder

- Maintained a clean and organized work area to promote safety, minimize weld contamination, and ensure equipment longevity.

- Successfully welded a variety of metal alloys, including steel, stainless steel, and aluminum, meeting specific customer requirements.

- Utilized specialized welding techniques, such as pulsation welding and micro welding, to achieve precise and controlled welds.

- Implemented lean manufacturing principles to improve welding productivity and reduce waste by 15%.

Spot Welder

- Utilized spot welding machines to seamlessly join metal components with pinpoint accuracy, adhering to stringent quality standards.

- Effectively set up and calibrated spot welding equipment to optimize weld parameters, ensuring optimal joint strength and minimal spatter.

- Proficiently performed post-weld inspections to assess weld integrity, identify defects, and ensure compliance with industry specifications.

- Collaborated with design engineers to develop and refine weld procedures, improving weld efficiency and reducing rework.

Accomplishments

- Developed innovative techniques for welding complex geometries, reducing production time by 25%.

- Identified and implemented costeffective electrode replacements, achieving significant savings in welding consumables.

- Trained and mentored junior welders, fostering a skilled and efficient team.

- Developed a preventative maintenance program for spot welding equipment, reducing downtime by 15%.

- Optimized welding parameters for different material thicknesses, ensuring consistent and highquality welds.

Awards

- Recognized as a Certified Welding Inspector (CWI) by the American Welding Society (AWS).

- Received the Excellence in Welding award from the International Institute of Welding (IIW).

- Awarded Welder of the Year by the National Welding Association (NWA).

- Recognized for outstanding contributions to the field of welding by the American Society for Metals (ASM).

Certificates

- AWS Certified Welder

- ASME Certified Welder

- OSHA 30-Hour Safety Training

- CPR and First Aid Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Spot Welder

- Highlight your specific skills and experience in spot welding.

- Include a portfolio of your work, such as photos or videos of your welds.

- Tailor your resume to each job you apply for.

- Proofread your resume carefully for any errors.

- Get feedback on your resume from a career counselor or mentor.

Essential Experience Highlights for a Strong Spot Welder Resume

- Operate and maintain spot welding machines to join metal components.

- Set up and adjust welding parameters, such as voltage, amperage, and weld time.

- Inspect welds for quality and ensure that they meet specifications.

- Troubleshoot and repair welding equipment.

- Follow safety procedures and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Spot Welder

What is spot welding?

Spot welding is a type of resistance welding that uses two copper alloy electrodes to apply pressure and an electric current to a localized area of two overlapping metal sheets. This causes the metal sheets to fuse together at the point of contact.

What are the benefits of spot welding?

Spot welding is a fast and efficient way to join metal sheets. It is also a relatively clean process, as it does not produce any fumes or sparks.

What are the different types of spot welding machines?

There are two main types of spot welding machines: rocker arm machines and C-frame machines. Rocker arm machines are more common and are used for a wider variety of applications. C-frame machines are typically used for heavier materials.

What are the safety precautions that should be taken when spot welding?

Spot welding can be a hazardous process, so it is important to take the following safety precautions: wear appropriate safety gear, such as gloves, safety glasses, and a welding helmet; keep the work area clean and free of debris; and never operate a spot welding machine if you are not properly trained.

What are the career opportunities for spot welders?

Spot welders can work in a variety of industries, including automotive, aerospace, and manufacturing. They can also work as self-employed contractors.

What is the average salary for a spot welder?

The average salary for a spot welder in the United States is $40,000 per year.