Are you a seasoned Stamping Bench Die Maker seeking a new career path? Discover our professionally built Stamping Bench Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

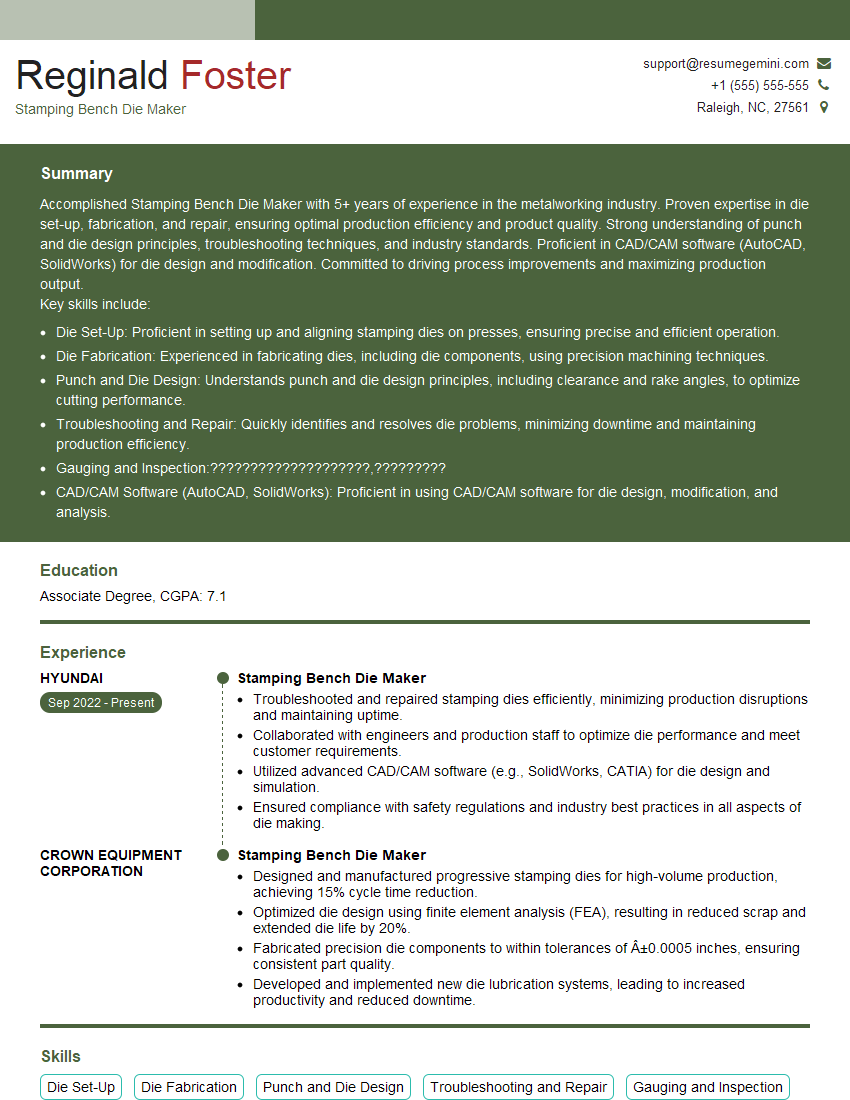

Reginald Foster

Stamping Bench Die Maker

Summary

Accomplished Stamping Bench Die Maker with 5+ years of experience in the metalworking industry. Proven expertise in die set-up, fabrication, and repair, ensuring optimal production efficiency and product quality. Strong understanding of punch and die design principles, troubleshooting techniques, and industry standards. Proficient in CAD/CAM software (AutoCAD, SolidWorks) for die design and modification. Committed to driving process improvements and maximizing production output.

Key skills include:

- Die Set-Up: Proficient in setting up and aligning stamping dies on presses, ensuring precise and efficient operation.

- Die Fabrication: Experienced in fabricating dies, including die components, using precision machining techniques.

- Punch and Die Design: Understands punch and die design principles, including clearance and rake angles, to optimize cutting performance.

- Troubleshooting and Repair: Quickly identifies and resolves die problems, minimizing downtime and maintaining production efficiency.

- Gauging and Inspection:????????????????????,?????????

- CAD/CAM Software (AutoCAD, SolidWorks): Proficient in using CAD/CAM software for die design, modification, and analysis.

Education

Associate Degree

August 2018

Skills

- Die Set-Up

- Die Fabrication

- Punch and Die Design

- Troubleshooting and Repair

- Gauging and Inspection

- CAD/CAM Software (AutoCAD, SolidWorks)

Work Experience

Stamping Bench Die Maker

- Troubleshooted and repaired stamping dies efficiently, minimizing production disruptions and maintaining uptime.

- Collaborated with engineers and production staff to optimize die performance and meet customer requirements.

- Utilized advanced CAD/CAM software (e.g., SolidWorks, CATIA) for die design and simulation.

- Ensured compliance with safety regulations and industry best practices in all aspects of die making.

Stamping Bench Die Maker

- Designed and manufactured progressive stamping dies for high-volume production, achieving 15% cycle time reduction.

- Optimized die design using finite element analysis (FEA), resulting in reduced scrap and extended die life by 20%.

- Fabricated precision die components to within tolerances of ±0.0005 inches, ensuring consistent part quality.

- Developed and implemented new die lubrication systems, leading to increased productivity and reduced downtime.

Accomplishments

- Successfully implemented a lean manufacturing process that improved overall efficiency by 20%

- Designed and fabricated a complex stamping die with tolerances within ±0.0005 inches

- Troubleshooted and resolved a production issue related to die wear, reducing downtime by 10%

- Collaborated with engineers to design and validate a new stamping press, ensuring optimal performance

- Utilized finite element analysis software to optimize die design, resulting in increased tool life

Awards

- Recognized for designing an innovative stamping die that reduced manufacturing time by 15%

- Awarded for developing a new die maintenance program that extended die life by 30%

- Received recognition for implementing a quality control system that reduced scrap rates by 25%

- Honored for developing a training program that improved employee skills and reduced rework

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Tool and Die Maker Journeyman Certificate

- American Society of Tool and Manufacturing Engineers (ASTME) Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stamping Bench Die Maker

- Highlight your experience and skills in die set-up, fabrication, and repair, as these are essential responsibilities of a Stamping Bench Die Maker.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and product quality.

- Showcase your proficiency in CAD/CAM software and how you have used it to improve die designs and streamline production processes.

- Include relevant certifications or training programs that demonstrate your commitment to professional development and industry knowledge.

Essential Experience Highlights for a Strong Stamping Bench Die Maker Resume

- Set up and align stamping dies on presses, ensuring precise and accurate operation.

- Fabricate die components using precision machining techniques, including milling, turning, and grinding.

- Design and modify punches and dies using CAD/CAM software, optimizing cutting performance and production efficiency.

- Troubleshoot and repair die problems, minimizing downtime and maintaining production output.

- Perform gauging and inspection throughout the die making process, ensuring accuracy and quality.

- Collaborate with engineers and production teams to improve die designs and optimize production processes.

- Stay abreast of industry best practices and technological advancements in die making and metalworking.

Frequently Asked Questions (FAQ’s) For Stamping Bench Die Maker

What is the primary role of a Stamping Bench Die Maker?

A Stamping Bench Die Maker is responsible for setting up, fabricating, and repairing dies used in stamping presses. They ensure that dies are properly aligned and functioning optimally to produce high-quality stamped parts.

What skills are required to be a successful Stamping Bench Die Maker?

Successful Stamping Bench Die Makers must have a strong understanding of die design and fabrication techniques, as well as proficiency in using precision machining equipment and CAD/CAM software. They should also possess excellent troubleshooting skills and a commitment to quality and efficiency.

What are the career prospects for Stamping Bench Die Makers?

Stamping Bench Die Makers are in high demand in various industries, including automotive, aerospace, and manufacturing. With experience and expertise, they can advance to roles such as Die Designer, Tooling Engineer, or Production Supervisor.

What is the average salary for a Stamping Bench Die Maker?

The average salary for a Stamping Bench Die Maker can vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers, which includes Stamping Bench Die Makers, was $56,980 in May 2021.

What are the educational requirements to become a Stamping Bench Die Maker?

While a high school diploma or equivalent is typically the minimum requirement, many Stamping Bench Die Makers pursue an Associate Degree in Tool and Die Making or a related field to enhance their skills and knowledge.

What advice would you give to someone interested in becoming a Stamping Bench Die Maker?

For those interested in becoming Stamping Bench Die Makers, it is recommended to gain practical experience through internships or apprenticeships. Additionally, pursuing a formal education in tool and die making or a related field can provide a solid foundation and enhance career opportunities.