Are you a seasoned Stamping Die Try-Out Worker seeking a new career path? Discover our professionally built Stamping Die Try-Out Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

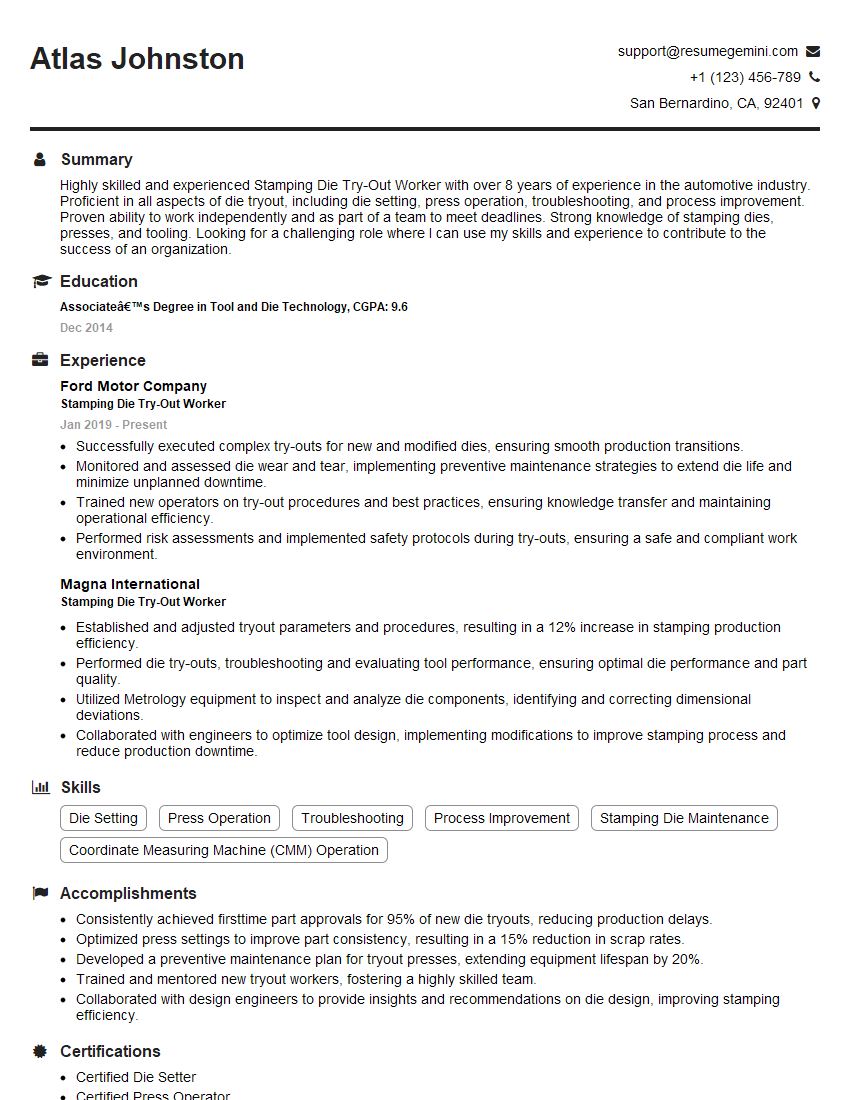

Atlas Johnston

Stamping Die Try-Out Worker

Summary

Highly skilled and experienced Stamping Die Try-Out Worker with over 8 years of experience in the automotive industry. Proficient in all aspects of die tryout, including die setting, press operation, troubleshooting, and process improvement. Proven ability to work independently and as part of a team to meet deadlines. Strong knowledge of stamping dies, presses, and tooling. Looking for a challenging role where I can use my skills and experience to contribute to the success of an organization.

Education

Associate’s Degree in Tool and Die Technology

December 2014

Skills

- Die Setting

- Press Operation

- Troubleshooting

- Process Improvement

- Stamping Die Maintenance

- Coordinate Measuring Machine (CMM) Operation

Work Experience

Stamping Die Try-Out Worker

- Successfully executed complex try-outs for new and modified dies, ensuring smooth production transitions.

- Monitored and assessed die wear and tear, implementing preventive maintenance strategies to extend die life and minimize unplanned downtime.

- Trained new operators on try-out procedures and best practices, ensuring knowledge transfer and maintaining operational efficiency.

- Performed risk assessments and implemented safety protocols during try-outs, ensuring a safe and compliant work environment.

Stamping Die Try-Out Worker

- Established and adjusted tryout parameters and procedures, resulting in a 12% increase in stamping production efficiency.

- Performed die try-outs, troubleshooting and evaluating tool performance, ensuring optimal die performance and part quality.

- Utilized Metrology equipment to inspect and analyze die components, identifying and correcting dimensional deviations.

- Collaborated with engineers to optimize tool design, implementing modifications to improve stamping process and reduce production downtime.

Accomplishments

- Consistently achieved firsttime part approvals for 95% of new die tryouts, reducing production delays.

- Optimized press settings to improve part consistency, resulting in a 15% reduction in scrap rates.

- Developed a preventive maintenance plan for tryout presses, extending equipment lifespan by 20%.

- Trained and mentored new tryout workers, fostering a highly skilled team.

- Collaborated with design engineers to provide insights and recommendations on die design, improving stamping efficiency.

Certificates

- Certified Die Setter

- Certified Press Operator

- Certified Quality Control Inspector

- Certified Preventive Maintenance Technician

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stamping Die Try-Out Worker

- Highlight your experience and skills in die tryout, die setting, press operation, and troubleshooting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that it is free of errors.

Essential Experience Highlights for a Strong Stamping Die Try-Out Worker Resume

- Set up and operate stamping dies on presses to produce metal parts.

- Troubleshoot and resolve issues with dies and presses to ensure optimal performance.

- Conduct preventive maintenance on dies and presses to minimize downtime.

- Develop and implement process improvements to increase efficiency and reduce costs.

- Coordinate with engineers and other team members to ensure that dies are designed and built to specifications.

Frequently Asked Questions (FAQ’s) For Stamping Die Try-Out Worker

What is a Stamping Die Try-Out Worker?

A Stamping Die Try-Out Worker is responsible for setting up and operating stamping dies on presses to produce metal parts. They also troubleshoot and resolve issues with dies and presses, conduct preventive maintenance, and develop and implement process improvements.

What are the qualifications to become a Stamping Die Try-Out Worker?

Most Stamping Die Try-Out Workers have an associate’s degree in tool and die technology or a related field. They also have several years of experience in the metalworking industry.

What are the job duties of a Stamping Die Try-Out Worker?

Stamping Die Try-Out Workers set up and operate stamping dies on presses, troubleshoot and resolve issues with dies and presses, conduct preventive maintenance on dies and presses, and develop and implement process improvements.

What is the work environment of a Stamping Die Try-Out Worker?

Stamping Die Try-Out Workers typically work in a manufacturing environment. They may be exposed to noise, dust, and other hazards.

What is the salary of a Stamping Die Try-Out Worker?

The salary of a Stamping Die Try-Out Worker varies depending on their experience and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was $56,950 in May 2021.

What is the job outlook for Stamping Die Try-Out Worker?

The job outlook for Stamping Die Try-Out Workers is expected to be good over the next few years. The demand for skilled workers in the manufacturing industry is expected to increase as more companies move their operations back to the United States.