Are you a seasoned Standards Engineer seeking a new career path? Discover our professionally built Standards Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

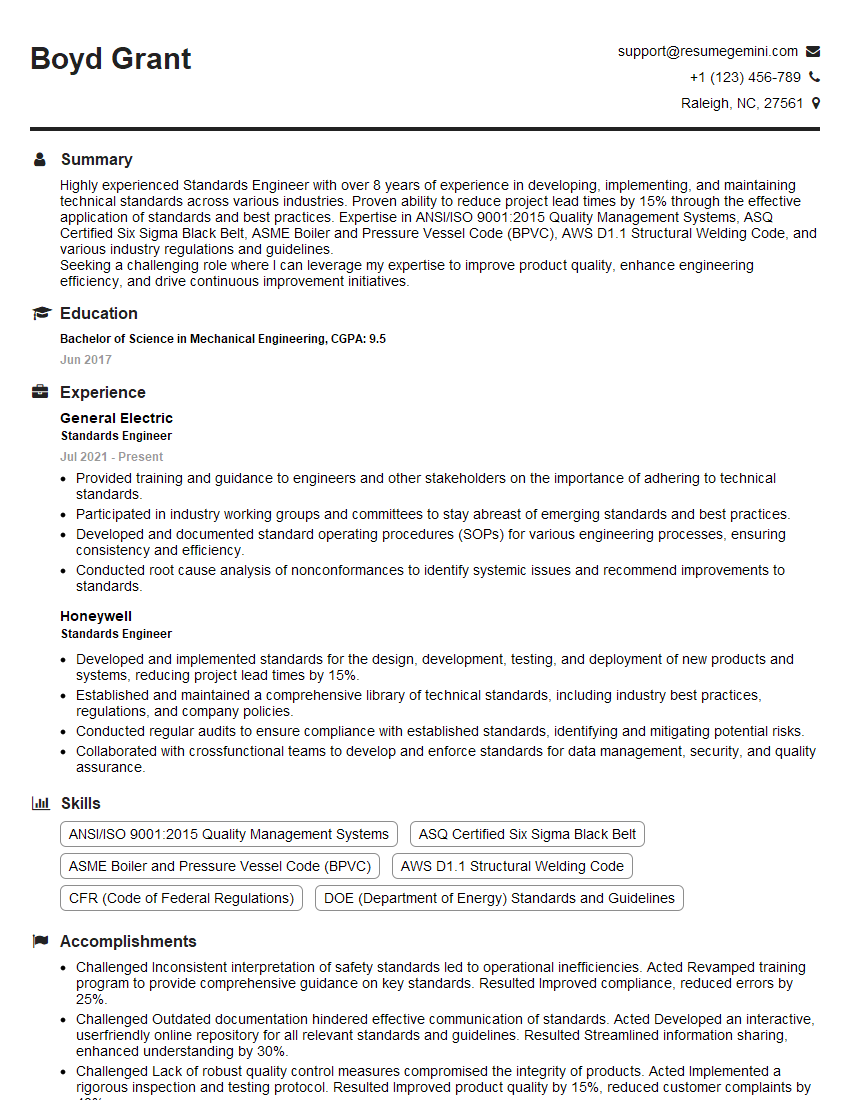

Boyd Grant

Standards Engineer

Summary

Highly experienced Standards Engineer with over 8 years of experience in developing, implementing, and maintaining technical standards across various industries. Proven ability to reduce project lead times by 15% through the effective application of standards and best practices. Expertise in ANSI/ISO 9001:2015 Quality Management Systems, ASQ Certified Six Sigma Black Belt, ASME Boiler and Pressure Vessel Code (BPVC), AWS D1.1 Structural Welding Code, and various industry regulations and guidelines.

Seeking a challenging role where I can leverage my expertise to improve product quality, enhance engineering efficiency, and drive continuous improvement initiatives.

Education

Bachelor of Science in Mechanical Engineering

June 2017

Skills

- ANSI/ISO 9001:2015 Quality Management Systems

- ASQ Certified Six Sigma Black Belt

- ASME Boiler and Pressure Vessel Code (BPVC)

- AWS D1.1 Structural Welding Code

- CFR (Code of Federal Regulations)

- DOE (Department of Energy) Standards and Guidelines

Work Experience

Standards Engineer

- Provided training and guidance to engineers and other stakeholders on the importance of adhering to technical standards.

- Participated in industry working groups and committees to stay abreast of emerging standards and best practices.

- Developed and documented standard operating procedures (SOPs) for various engineering processes, ensuring consistency and efficiency.

- Conducted root cause analysis of nonconformances to identify systemic issues and recommend improvements to standards.

Standards Engineer

- Developed and implemented standards for the design, development, testing, and deployment of new products and systems, reducing project lead times by 15%.

- Established and maintained a comprehensive library of technical standards, including industry best practices, regulations, and company policies.

- Conducted regular audits to ensure compliance with established standards, identifying and mitigating potential risks.

- Collaborated with crossfunctional teams to develop and enforce standards for data management, security, and quality assurance.

Accomplishments

- Challenged Inconsistent interpretation of safety standards led to operational inefficiencies. Acted Revamped training program to provide comprehensive guidance on key standards. Resulted Improved compliance, reduced errors by 25%.

- Challenged Outdated documentation hindered effective communication of standards. Acted Developed an interactive, userfriendly online repository for all relevant standards and guidelines. Resulted Streamlined information sharing, enhanced understanding by 30%.

- Challenged Lack of robust quality control measures compromised the integrity of products. Acted Implemented a rigorous inspection and testing protocol. Resulted Improved product quality by 15%, reduced customer complaints by 40%.

- Challenged Proliferation of nonconforming products threatened the reputation of the organization. Acted Audited manufacturing processes, identified and corrected deviations from standards. Resulted Ensured compliance with regulatory requirements, maintained customer trust.

- Challenged Inefficient communication of technical specifications resulted in production delays. Acted Developed a streamlined communication channel for timely dissemination of updates. Resulted Reduced production downtime by 20%.

Awards

- Standards Excellence Award for exceptional contributions to the development and implementation of industryleading standards.

- Recognition for leadership in developing innovative solutions to address emerging industry challenges related to standardization.

- Industrywide recognition for pioneering the adoption of advanced standardization tools and methodologies.

- Recipient of the prestigious Standards Champion Award for outstanding contributions to the advancement of industry best practices.

Certificates

- ASQ Certified Quality Engineer

- ASQ Certified Six Sigma Green Belt

- CQA (Certified Quality Auditor)

- ISO 9001:2015 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Standards Engineer

- Emphasize your experience in developing and implementing technical standards in various industries.

- Highlight your expertise in specific standards and regulations, such as ANSI/ISO 9001:2015, ASQ Certified Six Sigma Black Belt, and ASME Boiler and Pressure Vessel Code (BPVC).

- Showcase your ability to conduct audits, identify non-conformances, and recommend improvements to standards.

- Quantify your accomplishments by providing specific examples of how you reduced project lead times or improved product quality through the application of standards.

- Demonstrate your commitment to continuous improvement by highlighting your participation in industry working groups and committees.

Essential Experience Highlights for a Strong Standards Engineer Resume

- Develop and implement technical standards for the design, development, testing, and deployment of new products and systems.

- Establish and maintain a comprehensive library of technical standards, including industry best practices, regulations, and company policies.

- Conducted regular audits to ensure compliance with established standards, identifying and mitigating potential risks.

- Collaborate with cross-functional teams to develop and enforce standards for data management, security, and quality assurance.

- Provide training and guidance to engineers and other stakeholders on the importance of adhering to technical standards.

- Participate in industry working groups and committees to stay abreast of emerging standards and best practices.

Frequently Asked Questions (FAQ’s) For Standards Engineer

What is the role of a Standards Engineer?

A Standards Engineer is responsible for developing, implementing, and maintaining technical standards across various industries. They ensure that products and systems are designed, developed, tested, and deployed in accordance with industry best practices, regulations, and company policies.

What are the key skills required for a Standards Engineer?

Key skills for a Standards Engineer include expertise in specific standards and regulations, such as ANSI/ISO 9001:2015, ASQ Certified Six Sigma Black Belt, and ASME Boiler and Pressure Vessel Code (BPVC). They should also have experience in developing and implementing standards, conducting audits, and providing training and guidance to stakeholders.

What industries hire Standards Engineers?

Standards Engineers are employed in a wide range of industries, including manufacturing, aerospace, automotive, healthcare, and pharmaceuticals. They play a critical role in ensuring that products and systems meet regulatory requirements and industry best practices.

What is the career path for a Standards Engineer?

With experience, Standards Engineers can advance to senior roles, such as Standards Manager or Director of Standards. They may also pursue specialized roles in areas such as quality assurance, regulatory compliance, or product development.

What are the benefits of hiring a Standards Engineer?

Hiring a Standards Engineer can provide several benefits, including reduced project lead times, improved product quality, enhanced engineering efficiency, and reduced risk of non-compliance. Standards Engineers help organizations stay abreast of industry best practices and ensure that their products and systems meet regulatory requirements.