Are you a seasoned Steam Press Operator seeking a new career path? Discover our professionally built Steam Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

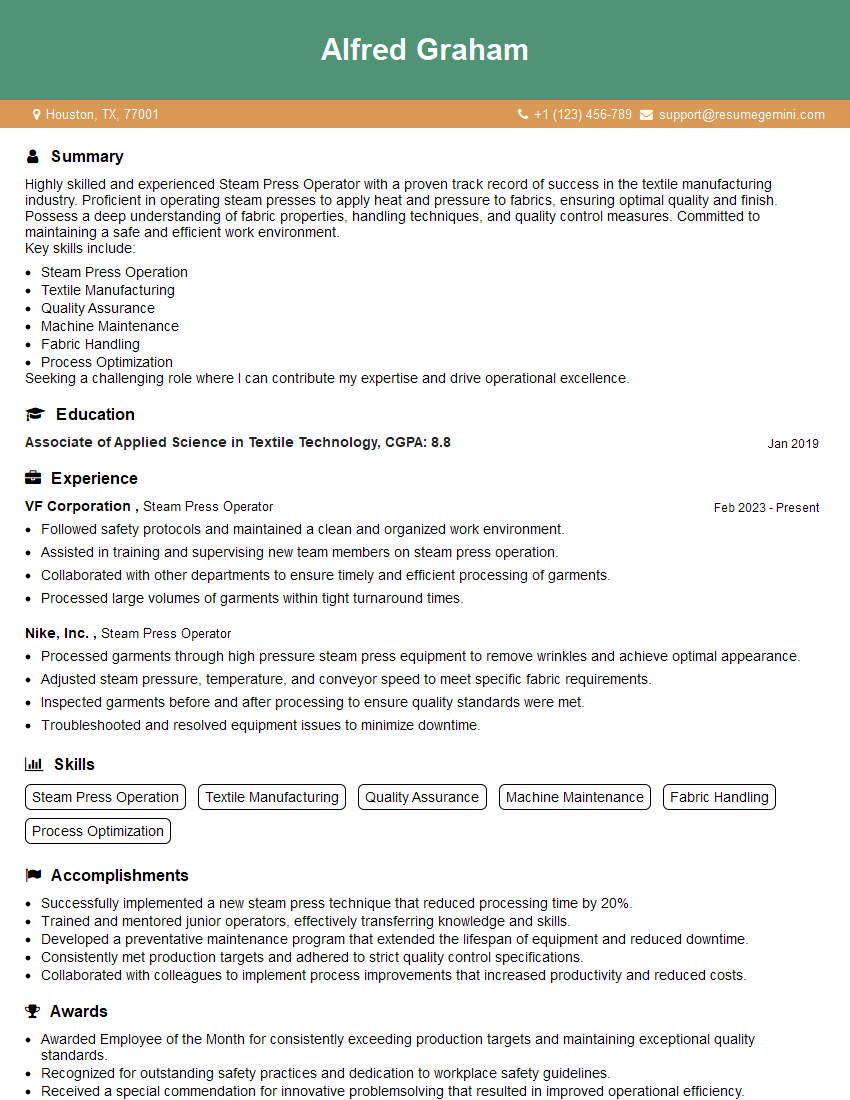

Alfred Graham

Steam Press Operator

Summary

Highly skilled and experienced Steam Press Operator with a proven track record of success in the textile manufacturing industry. Proficient in operating steam presses to apply heat and pressure to fabrics, ensuring optimal quality and finish. Possess a deep understanding of fabric properties, handling techniques, and quality control measures. Committed to maintaining a safe and efficient work environment.

Key skills include:

- Steam Press Operation

- Textile Manufacturing

- Quality Assurance

- Machine Maintenance

- Fabric Handling

- Process Optimization

Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate of Applied Science in Textile Technology

January 2019

Skills

- Steam Press Operation

- Textile Manufacturing

- Quality Assurance

- Machine Maintenance

- Fabric Handling

- Process Optimization

Work Experience

Steam Press Operator

- Followed safety protocols and maintained a clean and organized work environment.

- Assisted in training and supervising new team members on steam press operation.

- Collaborated with other departments to ensure timely and efficient processing of garments.

- Processed large volumes of garments within tight turnaround times.

Steam Press Operator

- Processed garments through high pressure steam press equipment to remove wrinkles and achieve optimal appearance.

- Adjusted steam pressure, temperature, and conveyor speed to meet specific fabric requirements.

- Inspected garments before and after processing to ensure quality standards were met.

- Troubleshooted and resolved equipment issues to minimize downtime.

Accomplishments

- Successfully implemented a new steam press technique that reduced processing time by 20%.

- Trained and mentored junior operators, effectively transferring knowledge and skills.

- Developed a preventative maintenance program that extended the lifespan of equipment and reduced downtime.

- Consistently met production targets and adhered to strict quality control specifications.

- Collaborated with colleagues to implement process improvements that increased productivity and reduced costs.

Awards

- Awarded Employee of the Month for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized for outstanding safety practices and dedication to workplace safety guidelines.

- Received a special commendation for innovative problemsolving that resulted in improved operational efficiency.

- Honored for leadership in optimizing work processes and promoting team collaboration.

Certificates

- Steam Press Operator Certification

- Textile Manufacturing Certificate

- OSHA Safety Certification

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steam Press Operator

- Highlight your experience and expertise in steam press operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your understanding of fabric properties and handling techniques.

- Emphasize your commitment to quality assurance and process optimization.

- Provide examples of your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Steam Press Operator Resume

- Operate steam presses to apply heat and pressure to fabrics, ensuring optimal quality and finish.

- Inspect fabrics before and after pressing to identify and correct any defects.

- Monitor and adjust press settings to achieve desired results, such as shrinkage, smoothness, and texture.

- Perform routine maintenance and repairs on steam presses to ensure proper functionality.

- Handle and move fabrics with care to prevent damage or contamination.

- Identify and implement process improvements to enhance efficiency and quality.

- Maintain a clean and organized work area, following established safety protocols.

Frequently Asked Questions (FAQ’s) For Steam Press Operator

What is the role of a Steam Press Operator?

A Steam Press Operator is responsible for operating steam presses to apply heat and pressure to fabrics, ensuring optimal quality and finish.

What are the key skills required for a Steam Press Operator?

Key skills for a Steam Press Operator include steam press operation, textile manufacturing, quality assurance, machine maintenance, fabric handling, and process optimization.

What are the career prospects for a Steam Press Operator?

Steam Press Operators can advance to roles such as Textile Production Supervisor, Quality Control Inspector, or Machine Maintenance Technician.

What is the average salary for a Steam Press Operator?

The average salary for a Steam Press Operator in the United States is around $35,000 per year.

What are the working conditions like for a Steam Press Operator?

Steam Press Operators typically work in manufacturing facilities, operating steam presses in a fast-paced environment. They may be exposed to heat, noise, and chemicals.

What are the educational requirements for a Steam Press Operator?

While formal education is not always required, an Associate of Applied Science in Textile Technology or a related field can be beneficial for a Steam Press Operator.

What are the personal qualities of a successful Steam Press Operator?

Successful Steam Press Operators are typically detail-oriented, have strong manual dexterity, and are able to work independently and as part of a team.