Are you a seasoned Steel Barrel Reamer seeking a new career path? Discover our professionally built Steel Barrel Reamer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

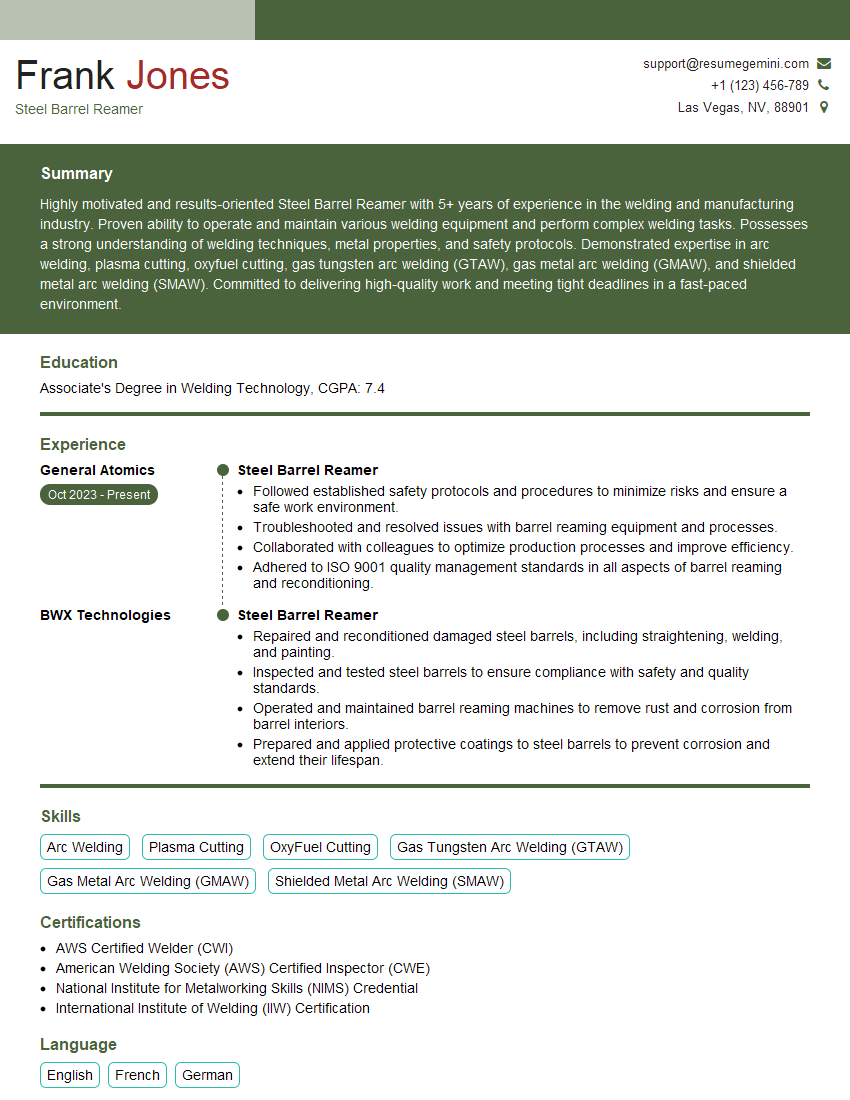

Frank Jones

Steel Barrel Reamer

Summary

Highly motivated and results-oriented Steel Barrel Reamer with 5+ years of experience in the welding and manufacturing industry. Proven ability to operate and maintain various welding equipment and perform complex welding tasks. Possesses a strong understanding of welding techniques, metal properties, and safety protocols. Demonstrated expertise in arc welding, plasma cutting, oxyfuel cutting, gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). Committed to delivering high-quality work and meeting tight deadlines in a fast-paced environment.

Education

Associate’s Degree in Welding Technology

September 2019

Skills

- Arc Welding

- Plasma Cutting

- OxyFuel Cutting

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Shielded Metal Arc Welding (SMAW)

Work Experience

Steel Barrel Reamer

- Followed established safety protocols and procedures to minimize risks and ensure a safe work environment.

- Troubleshooted and resolved issues with barrel reaming equipment and processes.

- Collaborated with colleagues to optimize production processes and improve efficiency.

- Adhered to ISO 9001 quality management standards in all aspects of barrel reaming and reconditioning.

Steel Barrel Reamer

- Repaired and reconditioned damaged steel barrels, including straightening, welding, and painting.

- Inspected and tested steel barrels to ensure compliance with safety and quality standards.

- Operated and maintained barrel reaming machines to remove rust and corrosion from barrel interiors.

- Prepared and applied protective coatings to steel barrels to prevent corrosion and extend their lifespan.

Certificates

- AWS Certified Welder (CWI)

- American Welding Society (AWS) Certified Inspector (CWE)

- National Institute for Metalworking Skills (NIMS) Credential

- International Institute of Welding (IIW) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Barrel Reamer

- Highlight your experience with different welding techniques, especially those mentioned in the job description.

- Showcase your knowledge of metal properties and welding safety protocols.

- Emphasize your ability to read and interpret blueprints and welding specifications accurately.

- Demonstrate your commitment to quality and meeting deadlines in a fast-paced environment.

Essential Experience Highlights for a Strong Steel Barrel Reamer Resume

- Operate and maintain a variety of welding equipment including arc welders, plasma cutters, and oxyfuel torches

- Read and interpret blueprints and welding specifications to ensure accurate fabrication of steel barrels

- Perform arc welding, plasma cutting, and oxyfuel cutting to fabricate steel barrels according to specifications

- Grind and finish welds to ensure a smooth and uniform surface

- Inspect welds for defects using visual and nondestructive testing methods

- Maintain a clean and organized work area, and adhere to all safety protocols

- Work independently and as part of a team to meet production goals

Frequently Asked Questions (FAQ’s) For Steel Barrel Reamer

What is the primary role of a Steel Barrel Reamer?

The primary role of a Steel Barrel Reamer is to operate and maintain welding equipment, read and interpret blueprints, perform various welding techniques, grind and finish welds, inspect welds for defects, and ensure a clean and organized work area while adhering to safety protocols.

What industries hire Steel Barrel Reamers?

Steel Barrel Reamers are employed in various industries that utilize welding and fabrication, such as manufacturing, construction, shipbuilding, automotive, and aerospace.

What are the essential skills for a successful Steel Barrel Reamer?

Essential skills for a Steel Barrel Reamer include proficiency in arc welding, plasma cutting, oxyfuel cutting, gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding. They must also possess knowledge of metal properties, welding techniques, and safety protocols.

What is the average salary range for a Steel Barrel Reamer?

The average salary range for a Steel Barrel Reamer varies depending on experience, location, and industry. According to Indeed, the average salary for a Steel Barrel Reamer in the United States is around $40,000 to $60,000 per year.

What are the career advancement opportunities for a Steel Barrel Reamer?

With experience and additional training, Steel Barrel Reamers can advance to roles such as Welding Supervisor, Quality Control Inspector, or Welding Engineer.

What certifications are beneficial for Steel Barrel Reamers?

Beneficial certifications for Steel Barrel Reamers include AWS Certified Welder, Certified Welding Inspector, and OSHA Safety Certification.

What is the job outlook for Steel Barrel Reamers?

The job outlook for Steel Barrel Reamers is expected to be stable in the coming years due to the ongoing demand for skilled welders in various industries.

What are some tips for writing a standout Steel Barrel Reamer resume?

To write a standout Steel Barrel Reamer resume, highlight your relevant welding skills and experience, quantify your accomplishments, use action verbs, proofread carefully, and tailor your resume to the specific job you’re applying for.