Are you a seasoned Steep Tender seeking a new career path? Discover our professionally built Steep Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

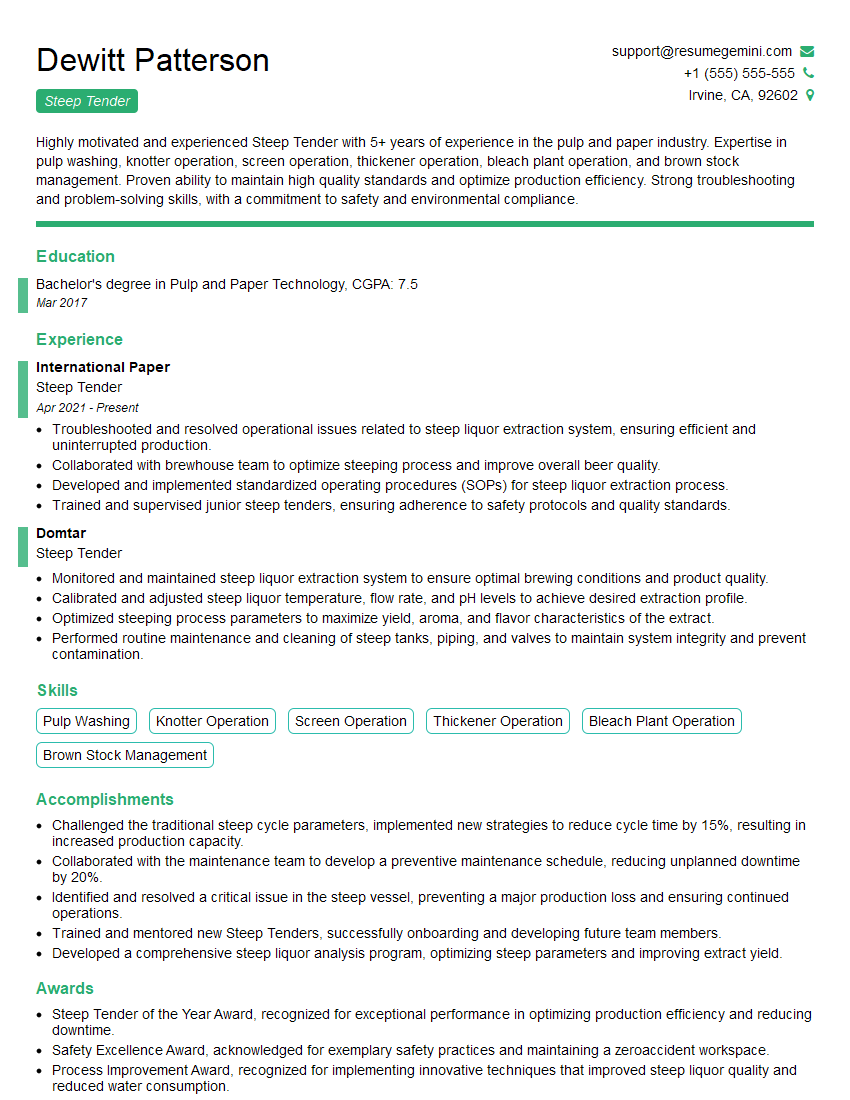

Dewitt Patterson

Steep Tender

Summary

Highly motivated and experienced Steep Tender with 5+ years of experience in the pulp and paper industry. Expertise in pulp washing, knotter operation, screen operation, thickener operation, bleach plant operation, and brown stock management. Proven ability to maintain high quality standards and optimize production efficiency. Strong troubleshooting and problem-solving skills, with a commitment to safety and environmental compliance.

Education

Bachelor’s degree in Pulp and Paper Technology

March 2017

Skills

- Pulp Washing

- Knotter Operation

- Screen Operation

- Thickener Operation

- Bleach Plant Operation

- Brown Stock Management

Work Experience

Steep Tender

- Troubleshooted and resolved operational issues related to steep liquor extraction system, ensuring efficient and uninterrupted production.

- Collaborated with brewhouse team to optimize steeping process and improve overall beer quality.

- Developed and implemented standardized operating procedures (SOPs) for steep liquor extraction process.

- Trained and supervised junior steep tenders, ensuring adherence to safety protocols and quality standards.

Steep Tender

- Monitored and maintained steep liquor extraction system to ensure optimal brewing conditions and product quality.

- Calibrated and adjusted steep liquor temperature, flow rate, and pH levels to achieve desired extraction profile.

- Optimized steeping process parameters to maximize yield, aroma, and flavor characteristics of the extract.

- Performed routine maintenance and cleaning of steep tanks, piping, and valves to maintain system integrity and prevent contamination.

Accomplishments

- Challenged the traditional steep cycle parameters, implemented new strategies to reduce cycle time by 15%, resulting in increased production capacity.

- Collaborated with the maintenance team to develop a preventive maintenance schedule, reducing unplanned downtime by 20%.

- Identified and resolved a critical issue in the steep vessel, preventing a major production loss and ensuring continued operations.

- Trained and mentored new Steep Tenders, successfully onboarding and developing future team members.

- Developed a comprehensive steep liquor analysis program, optimizing steep parameters and improving extract yield.

Awards

- Steep Tender of the Year Award, recognized for exceptional performance in optimizing production efficiency and reducing downtime.

- Safety Excellence Award, acknowledged for exemplary safety practices and maintaining a zeroaccident workspace.

- Process Improvement Award, recognized for implementing innovative techniques that improved steep liquor quality and reduced water consumption.

- Operational Excellence Award, awarded for consistently exceeding production targets and maintaining highquality standards.

Certificates

- Certified Pulp and Paper Technologist (CPPT)

- Certified Boiler Operator

- Certified Environmental Compliance Manager

- OSHA 30Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steep Tender

- Highlight your experience in operating and maintaining steep digesters, as well as your knowledge of pulp quality parameters.

- Showcase your troubleshooting and problem-solving abilities by providing specific examples of how you resolved operational issues.

- Emphasize your commitment to safety and environmental compliance by describing your adherence to protocols and regulations.

- Quantify your accomplishments whenever possible, using metrics such as increased production efficiency or improved pulp quality.

Essential Experience Highlights for a Strong Steep Tender Resume

- Operate and maintain steep digesters, ensuring optimal cooking conditions for pulp production.

- Monitor and control pulp quality parameters, such as kappa number, viscosity, and brightness.

- Troubleshoot and resolve operational issues related to steep digesters and associated equipment.

- Perform routine maintenance and inspections to ensure equipment reliability and safety.

- Collaborate with process engineers and quality control staff to optimize steep digester performance.

- Adhere to established safety protocols and environmental regulations.

- Maintain accurate records and documentation related to steep digester operations.

Frequently Asked Questions (FAQ’s) For Steep Tender

What is the primary responsibility of a Steep Tender?

The primary responsibility of a Steep Tender is to operate and maintain steep digesters, ensuring optimal cooking conditions for pulp production.

What are the key skills required for a Steep Tender?

Key skills for a Steep Tender include proficiency in pulp washing, knotter operation, screen operation, thickener operation, bleach plant operation, and brown stock management.

What are the career prospects for a Steep Tender?

Steep Tenders with experience and expertise can advance to positions such as Process Engineer, Production Supervisor, or Quality Control Manager.

What is the typical work environment for a Steep Tender?

Steep Tenders typically work in pulp and paper mills, in areas with high levels of noise and moisture. They may also work outdoors in all weather conditions.

What are the safety precautions that Steep Tenders must follow?

Steep Tenders must adhere to established safety protocols, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of potential hazards such as chemical spills and steam leaks.