Are you a seasoned Stopper Maker seeking a new career path? Discover our professionally built Stopper Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

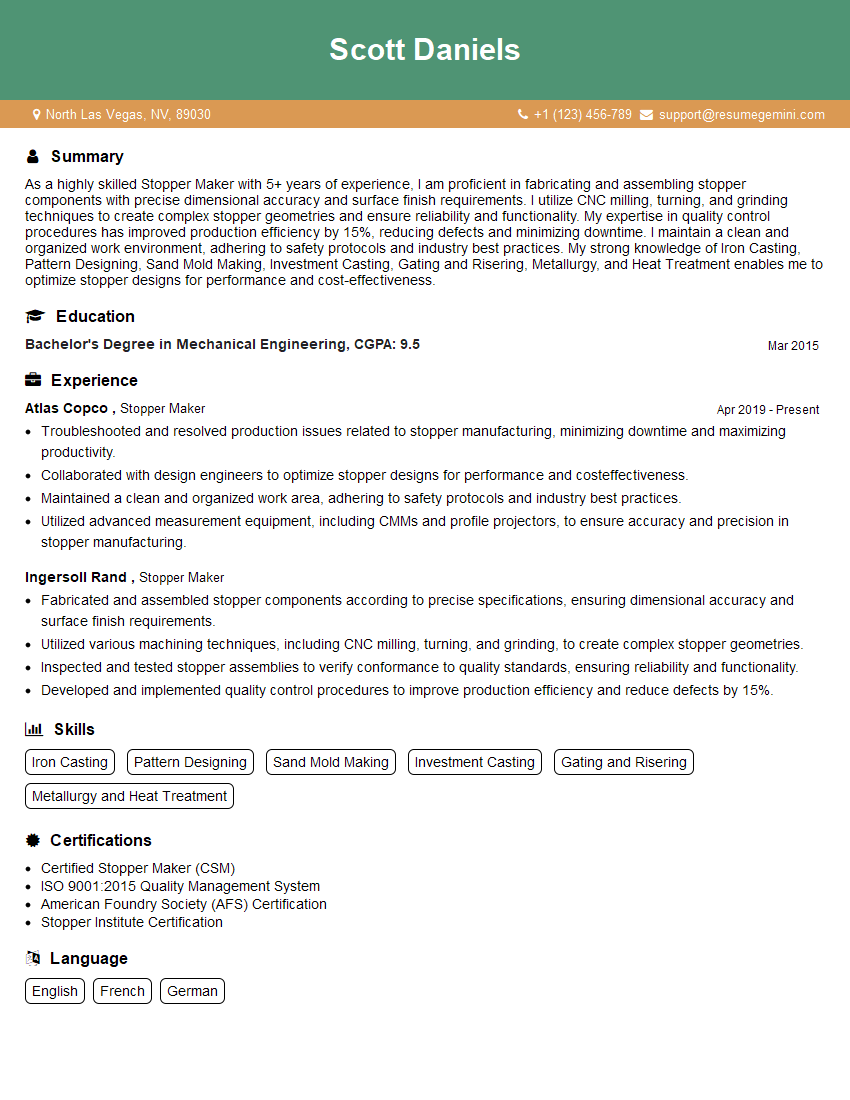

Scott Daniels

Stopper Maker

Summary

As a highly skilled Stopper Maker with 5+ years of experience, I am proficient in fabricating and assembling stopper components with precise dimensional accuracy and surface finish requirements. I utilize CNC milling, turning, and grinding techniques to create complex stopper geometries and ensure reliability and functionality. My expertise in quality control procedures has improved production efficiency by 15%, reducing defects and minimizing downtime. I maintain a clean and organized work environment, adhering to safety protocols and industry best practices. My strong knowledge of Iron Casting, Pattern Designing, Sand Mold Making, Investment Casting, Gating and Risering, Metallurgy, and Heat Treatment enables me to optimize stopper designs for performance and cost-effectiveness.

Education

Bachelor’s Degree in Mechanical Engineering

March 2015

Skills

- Iron Casting

- Pattern Designing

- Sand Mold Making

- Investment Casting

- Gating and Risering

- Metallurgy and Heat Treatment

Work Experience

Stopper Maker

- Troubleshooted and resolved production issues related to stopper manufacturing, minimizing downtime and maximizing productivity.

- Collaborated with design engineers to optimize stopper designs for performance and costeffectiveness.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Utilized advanced measurement equipment, including CMMs and profile projectors, to ensure accuracy and precision in stopper manufacturing.

Stopper Maker

- Fabricated and assembled stopper components according to precise specifications, ensuring dimensional accuracy and surface finish requirements.

- Utilized various machining techniques, including CNC milling, turning, and grinding, to create complex stopper geometries.

- Inspected and tested stopper assemblies to verify conformance to quality standards, ensuring reliability and functionality.

- Developed and implemented quality control procedures to improve production efficiency and reduce defects by 15%.

Certificates

- Certified Stopper Maker (CSM)

- ISO 9001:2015 Quality Management System

- American Foundry Society (AFS) Certification

- Stopper Institute Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stopper Maker

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your experience with specialized equipment and software.

- Showcase your understanding of stopper manufacturing processes and quality control techniques.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Stopper Maker Resume

- Fabricate and assemble stopper components to precise specifications, ensuring dimensional accuracy and surface finish requirements.

- Utilize CNC milling, turning, and grinding techniques to create complex stopper geometries.

- Inspect and test stopper assemblies to verify conformance to quality standards, ensuring reliability and functionality.

- Develop and implement quality control procedures to improve production efficiency and reduce defects.

- Troubleshoot and resolve production issues related to stopper manufacturing, minimizing downtime and maximizing productivity.

- Collaborate with design engineers to optimize stopper designs for performance and cost-effectiveness.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Stopper Maker

What are the key skills required for a successful Stopper Maker?

Key skills for a successful Stopper Maker include proficiency in Iron Casting, Pattern Designing, Sand Mold Making, Investment Casting, Gating and Risering, Metallurgy, and Heat Treatment. They should also have experience in fabricating and assembling stopper components to precise specifications, utilizing CNC milling, turning, and grinding techniques to create complex stopper geometries. Additionally, they should be able to inspect and test stopper assemblies, develop and implement quality control procedures, and troubleshoot and resolve production issues.

What are the career prospects for Stopper Makers?

Stopper Makers can advance their careers by developing expertise in specialized areas, such as advanced machining techniques, quality control management, or design engineering. They may also move into supervisory or management roles, overseeing production teams or departments. With experience and additional training, Stopper Makers can also transition into related fields, such as manufacturing engineering or product development.

What are the challenges faced by Stopper Makers in the industry?

Stopper Makers face several challenges in the industry, including the need to meet increasingly stringent quality standards, improve production efficiency, and reduce costs. They must also stay up-to-date with advancements in technology and manufacturing techniques to remain competitive. Additionally, Stopper Makers may face challenges related to material shortages, supply chain disruptions, and environmental regulations.

How can Stopper Makers stay competitive in the job market?

Stopper Makers can stay competitive in the job market by continuously developing their skills and knowledge, embracing new technologies, and seeking opportunities for professional growth. They can also network with industry professionals, attend conferences, and participate in training programs to enhance their expertise. Additionally, Stopper Makers should be adaptable and willing to learn new processes and techniques to meet the evolving demands of the industry.

What are the key qualities that employers look for when hiring Stopper Makers?

Employers hiring Stopper Makers typically seek candidates with a strong understanding of stopper manufacturing processes, quality control techniques, and safety protocols. They value candidates with experience in operating and maintaining specialized equipment, such as CNC machines and CMMs. Additionally, employers look for candidates with good problem-solving skills, attention to detail, and a commitment to quality workmanship.

What are the typical working conditions for Stopper Makers?

Stopper Makers typically work in manufacturing facilities, operating and maintaining machinery in a production environment. They may work in a team environment, collaborating with other team members to achieve production goals. Stopper Makers must be able to work independently and follow instructions carefully. They may also be required to work overtime or on weekends to meet production demands.

What are the safety precautions that Stopper Makers should follow?

Stopper Makers should follow all safety protocols and guidelines established by their employers and industry regulations. This includes wearing appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. They should also be aware of potential hazards in the work environment, such as moving machinery, sharp tools, and hazardous chemicals. Stopper Makers should receive proper training on safety procedures and regularly attend safety meetings to stay up-to-date on best practices.