Are you a seasoned Straight Bevel Gear Generator Set-Up Operator seeking a new career path? Discover our professionally built Straight Bevel Gear Generator Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

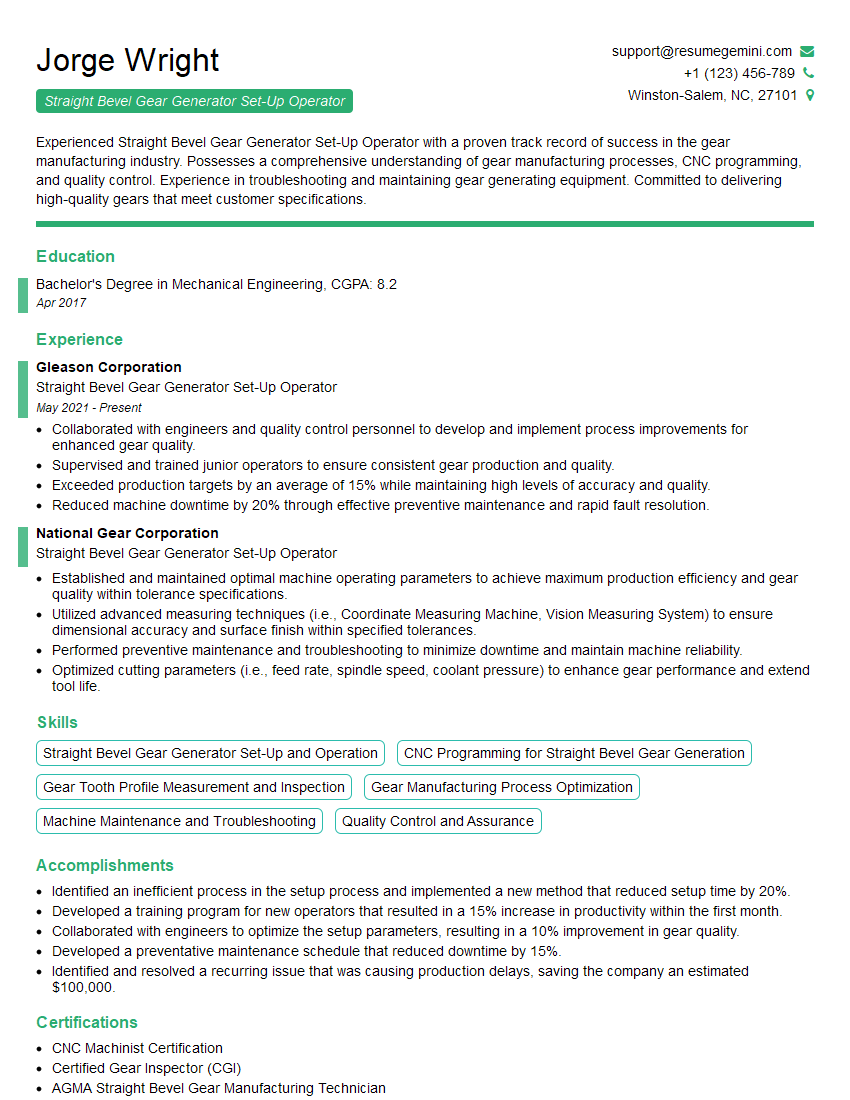

Jorge Wright

Straight Bevel Gear Generator Set-Up Operator

Summary

Experienced Straight Bevel Gear Generator Set-Up Operator with a proven track record of success in the gear manufacturing industry. Possesses a comprehensive understanding of gear manufacturing processes, CNC programming, and quality control. Experience in troubleshooting and maintaining gear generating equipment. Committed to delivering high-quality gears that meet customer specifications.

Education

Bachelor’s Degree in Mechanical Engineering

April 2017

Skills

- Straight Bevel Gear Generator Set-Up and Operation

- CNC Programming for Straight Bevel Gear Generation

- Gear Tooth Profile Measurement and Inspection

- Gear Manufacturing Process Optimization

- Machine Maintenance and Troubleshooting

- Quality Control and Assurance

Work Experience

Straight Bevel Gear Generator Set-Up Operator

- Collaborated with engineers and quality control personnel to develop and implement process improvements for enhanced gear quality.

- Supervised and trained junior operators to ensure consistent gear production and quality.

- Exceeded production targets by an average of 15% while maintaining high levels of accuracy and quality.

- Reduced machine downtime by 20% through effective preventive maintenance and rapid fault resolution.

Straight Bevel Gear Generator Set-Up Operator

- Established and maintained optimal machine operating parameters to achieve maximum production efficiency and gear quality within tolerance specifications.

- Utilized advanced measuring techniques (i.e., Coordinate Measuring Machine, Vision Measuring System) to ensure dimensional accuracy and surface finish within specified tolerances.

- Performed preventive maintenance and troubleshooting to minimize downtime and maintain machine reliability.

- Optimized cutting parameters (i.e., feed rate, spindle speed, coolant pressure) to enhance gear performance and extend tool life.

Accomplishments

- Identified an inefficient process in the setup process and implemented a new method that reduced setup time by 20%.

- Developed a training program for new operators that resulted in a 15% increase in productivity within the first month.

- Collaborated with engineers to optimize the setup parameters, resulting in a 10% improvement in gear quality.

- Developed a preventative maintenance schedule that reduced downtime by 15%.

- Identified and resolved a recurring issue that was causing production delays, saving the company an estimated $100,000.

Certificates

- CNC Machinist Certification

- Certified Gear Inspector (CGI)

- AGMA Straight Bevel Gear Manufacturing Technician

- ISO 9001:2015 Quality Management System Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Straight Bevel Gear Generator Set-Up Operator

- Highlight your experience in operating and programming straight bevel gear generator machines.

- Quantify your accomplishments by providing specific examples of how you have improved gear quality or efficiency.

- Demonstrate your knowledge of gear manufacturing processes and quality control standards.

- Emphasize your ability to troubleshoot and maintain gear generating equipment.

Essential Experience Highlights for a Strong Straight Bevel Gear Generator Set-Up Operator Resume

- Set up and operate straight bevel gear generator machines to produce gears according to customer specifications.

- Program and operate CNC machines to generate gear tooth profiles.

- Measure and inspect gear tooth profiles using precision measuring equipment.

- Optimize gear manufacturing processes to improve efficiency and quality.

- Troubleshoot and maintain gear generating equipment to ensure optimal performance.

- Conduct quality control inspections on gears to ensure they meet established standards.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Straight Bevel Gear Generator Set-Up Operator

What are the duties and responsibilities of a Straight Bevel Gear Generator Set-Up Operator?

Straight Bevel Gear Generator Set-Up Operators are responsible for setting up and operating straight bevel gear generator machines to produce gears according to customer specifications. They also program and operate CNC machines to generate gear tooth profiles, measure and inspect gear tooth profiles using precision measuring equipment, optimize gear manufacturing processes to improve efficiency and quality, troubleshoot and maintain gear generating equipment to ensure optimal performance, conduct quality control inspections on gears to ensure they meet established standards, and adhere to safety protocols and maintain a clean and organized work area.

What are the qualifications for becoming a Straight Bevel Gear Generator Set-Up Operator?

Most Straight Bevel Gear Generator Set-Up Operators have a high school diploma or equivalent and have completed an apprenticeship or training program in gear manufacturing. Some employers may require a bachelor’s degree in mechanical engineering or a related field.

What are the career prospects for a Straight Bevel Gear Generator Set-Up Operator?

Straight Bevel Gear Generator Set-Up Operators can advance to positions such as supervisor, quality control manager, or manufacturing engineer.

What is the average salary for a Straight Bevel Gear Generator Set-Up Operator?

The average salary for a Straight Bevel Gear Generator Set-Up Operator is $60,000 per year.

What are the working conditions for a Straight Bevel Gear Generator Set-Up Operator?

Straight Bevel Gear Generator Set-Up Operators typically work in a manufacturing environment and may be exposed to loud noises and hazardous materials. They may also be required to work overtime or on weekends.

What are the benefits of working as a Straight Bevel Gear Generator Set-Up Operator?

Straight Bevel Gear Generator Set-Up Operators enjoy a variety of benefits, including health insurance, paid time off, and retirement benefits.

What are the challenges of working as a Straight Bevel Gear Generator Set-Up Operator?

Straight Bevel Gear Generator Set-Up Operators may face challenges such as working with heavy machinery, meeting production deadlines, and working in a noisy environment.