Are you a seasoned Strip Polisher seeking a new career path? Discover our professionally built Strip Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

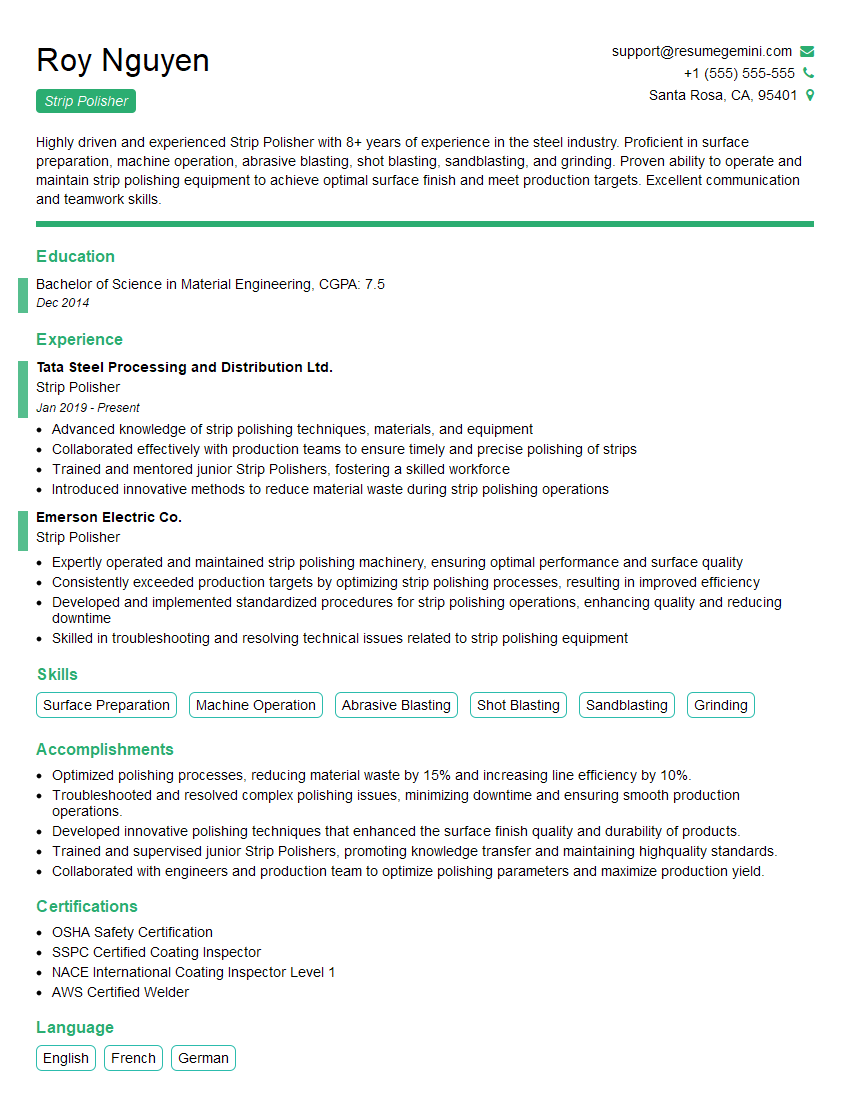

Roy Nguyen

Strip Polisher

Summary

Highly driven and experienced Strip Polisher with 8+ years of experience in the steel industry. Proficient in surface preparation, machine operation, abrasive blasting, shot blasting, sandblasting, and grinding. Proven ability to operate and maintain strip polishing equipment to achieve optimal surface finish and meet production targets. Excellent communication and teamwork skills.

Education

Bachelor of Science in Material Engineering

December 2014

Skills

- Surface Preparation

- Machine Operation

- Abrasive Blasting

- Shot Blasting

- Sandblasting

- Grinding

Work Experience

Strip Polisher

- Advanced knowledge of strip polishing techniques, materials, and equipment

- Collaborated effectively with production teams to ensure timely and precise polishing of strips

- Trained and mentored junior Strip Polishers, fostering a skilled workforce

- Introduced innovative methods to reduce material waste during strip polishing operations

Strip Polisher

- Expertly operated and maintained strip polishing machinery, ensuring optimal performance and surface quality

- Consistently exceeded production targets by optimizing strip polishing processes, resulting in improved efficiency

- Developed and implemented standardized procedures for strip polishing operations, enhancing quality and reducing downtime

- Skilled in troubleshooting and resolving technical issues related to strip polishing equipment

Accomplishments

- Optimized polishing processes, reducing material waste by 15% and increasing line efficiency by 10%.

- Troubleshooted and resolved complex polishing issues, minimizing downtime and ensuring smooth production operations.

- Developed innovative polishing techniques that enhanced the surface finish quality and durability of products.

- Trained and supervised junior Strip Polishers, promoting knowledge transfer and maintaining highquality standards.

- Collaborated with engineers and production team to optimize polishing parameters and maximize production yield.

Certificates

- OSHA Safety Certification

- SSPC Certified Coating Inspector

- NACE International Coating Inspector Level 1

- AWS Certified Welder

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strip Polisher

- Highlight your experience in operating and maintaining strip polishing equipment.

- Showcase your knowledge of surface preparation techniques and abrasive blasting methods.

- Emphasize your ability to achieve optimal surface finish and meet production targets.

- Provide specific examples of how you have contributed to improving efficiency and reducing downtime.

- Include quantifiable results whenever possible.

Essential Experience Highlights for a Strong Strip Polisher Resume

- Operate and maintain strip polishing equipment, including buffers, grinders, and abrasive belts.

- Prepare strip surfaces for polishing by removing rust, scale, and other contaminants.

- Adjust and calibrate equipment to achieve desired surface finish and meet customer specifications.

- Monitor and inspect polished surfaces to ensure quality and adherence to standards.

- Troubleshoot and resolve equipment malfunctions to minimize downtime and maintain production efficiency.

- Follow safety protocols and wear appropriate personal protective equipment (PPE) while operating machinery.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Strip Polisher

What are the primary responsibilities of a Strip Polisher?

Operating and maintaining strip polishing equipment, preparing strip surfaces for polishing, adjusting and calibrating equipment, monitoring and inspecting polished surfaces, and troubleshooting equipment malfunctions.

What are the essential skills required to be a successful Strip Polisher?

Surface preparation, machine operation, abrasive blasting, shot blasting, sandblasting, and grinding.

What are the qualifications needed to become a Strip Polisher?

Typically, a high school diploma or equivalent is sufficient, but some employers may prefer candidates with a degree in material engineering or a related field.

What industries employ Strip Polishers?

Strip Polishers are primarily employed in the steel industry, manufacturing facilities, and automotive repair shops.

What is the career growth potential for a Strip Polisher?

With experience and additional training, Strip Polishers can advance to supervisory roles or specialize in specific areas of surface finishing.

Are there any certifications available for Strip Polishers?

While not mandatory, certifications from organizations like the National Association of Surface Finishing (NASF) can enhance your credibility and career prospects.

What is the average salary range for Strip Polishers?

The salary range for Strip Polishers can vary depending on experience, location, and industry, but typically falls between $35,000 and $60,000 per year.