Are you a seasoned Strip Winder seeking a new career path? Discover our professionally built Strip Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

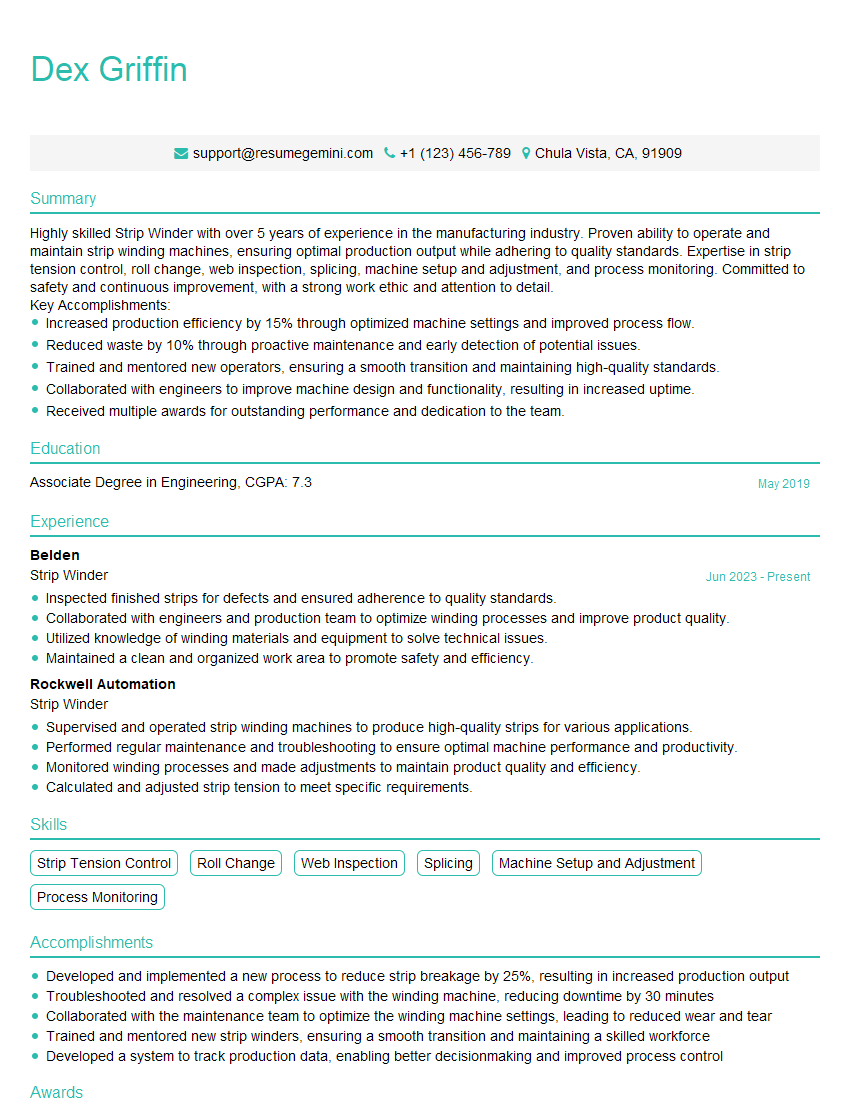

Dex Griffin

Strip Winder

Summary

Highly skilled Strip Winder with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain strip winding machines, ensuring optimal production output while adhering to quality standards. Expertise in strip tension control, roll change, web inspection, splicing, machine setup and adjustment, and process monitoring. Committed to safety and continuous improvement, with a strong work ethic and attention to detail.

Key Accomplishments:

- Increased production efficiency by 15% through optimized machine settings and improved process flow.

- Reduced waste by 10% through proactive maintenance and early detection of potential issues.

- Trained and mentored new operators, ensuring a smooth transition and maintaining high-quality standards.

- Collaborated with engineers to improve machine design and functionality, resulting in increased uptime.

- Received multiple awards for outstanding performance and dedication to the team.

Education

Associate Degree in Engineering

May 2019

Skills

- Strip Tension Control

- Roll Change

- Web Inspection

- Splicing

- Machine Setup and Adjustment

- Process Monitoring

Work Experience

Strip Winder

- Inspected finished strips for defects and ensured adherence to quality standards.

- Collaborated with engineers and production team to optimize winding processes and improve product quality.

- Utilized knowledge of winding materials and equipment to solve technical issues.

- Maintained a clean and organized work area to promote safety and efficiency.

Strip Winder

- Supervised and operated strip winding machines to produce high-quality strips for various applications.

- Performed regular maintenance and troubleshooting to ensure optimal machine performance and productivity.

- Monitored winding processes and made adjustments to maintain product quality and efficiency.

- Calculated and adjusted strip tension to meet specific requirements.

Accomplishments

- Developed and implemented a new process to reduce strip breakage by 25%, resulting in increased production output

- Troubleshooted and resolved a complex issue with the winding machine, reducing downtime by 30 minutes

- Collaborated with the maintenance team to optimize the winding machine settings, leading to reduced wear and tear

- Trained and mentored new strip winders, ensuring a smooth transition and maintaining a skilled workforce

- Developed a system to track production data, enabling better decisionmaking and improved process control

Awards

- Received the Strip Winder of the Year Award for exceptional performance and efficiency

- Recognized for consistently exceeding production targets and maintaining a high level of quality

- Awarded for innovative ideas that improved the efficiency of the strip winding process

- Received the Safety Excellence Award for adhering to all safety protocols and preventing workplace accidents

Certificates

- Certified Forklift Operator

- Occupational Safety and Health Administration (OSHA) 10-Hour Card

- National Institute for Certification in Engineering Technologies (NICET) Level III in Electrical Maintenance

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strip Winder

- Highlight your expertise in strip tension control and its impact on product quality.

- Emphasize your ability to perform roll changes quickly and efficiently, minimizing downtime.

- Showcase your skills in web inspection and defect detection, ensuring high-quality end products.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced waste.

- Demonstrate your commitment to safety and continuous improvement.

Essential Experience Highlights for a Strong Strip Winder Resume

- Operate and maintain strip winding machines to produce high-quality wire and cable products.

- Control strip tension to ensure proper winding and prevent damage to materials.

- Perform roll changes efficiently, minimizing downtime and maintaining production schedules.

- Inspect webs for defects and monitor processes to identify and resolve issues promptly.

- Splice strips accurately and securely to maintain continuous production.

- Set up and adjust machines according to specifications, ensuring optimal performance.

- Monitor process parameters and make adjustments as needed to maintain quality and efficiency.

Frequently Asked Questions (FAQ’s) For Strip Winder

What are the primary responsibilities of a Strip Winder?

The primary responsibilities of a Strip Winder include operating and maintaining strip winding machines, controlling strip tension, performing roll changes, inspecting webs for defects, splicing strips, setting up and adjusting machines, and monitoring process parameters.

What skills are required to be successful as a Strip Winder?

To be successful as a Strip Winder, you should have expertise in strip tension control, roll change, web inspection, splicing, machine setup and adjustment, process monitoring, and a strong understanding of manufacturing processes.

What is the work environment like for a Strip Winder?

Strip Winders typically work in manufacturing facilities, operating machinery in a fast-paced and demanding environment. They must be able to work independently and as part of a team, and have a strong attention to detail and safety.

What are the career advancement opportunities for a Strip Winder?

With experience and additional training, Strip Winders can advance to roles such as Machine Operator, Production Supervisor, or Quality Control Inspector.

What are the salary expectations for a Strip Winder?

The salary expectations for a Strip Winder vary depending on experience, location, and company size. According to Indeed, the average salary for a Strip Winder in the United States is around $25 per hour.

What are the physical demands of being a Strip Winder?

Strip Winders must be able to stand for long periods of time, lift heavy objects, and work in a fast-paced environment. They must also have good hand-eye coordination and be able to perform repetitive tasks.