Are you a seasoned Stripping Cutter and Winder seeking a new career path? Discover our professionally built Stripping Cutter and Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

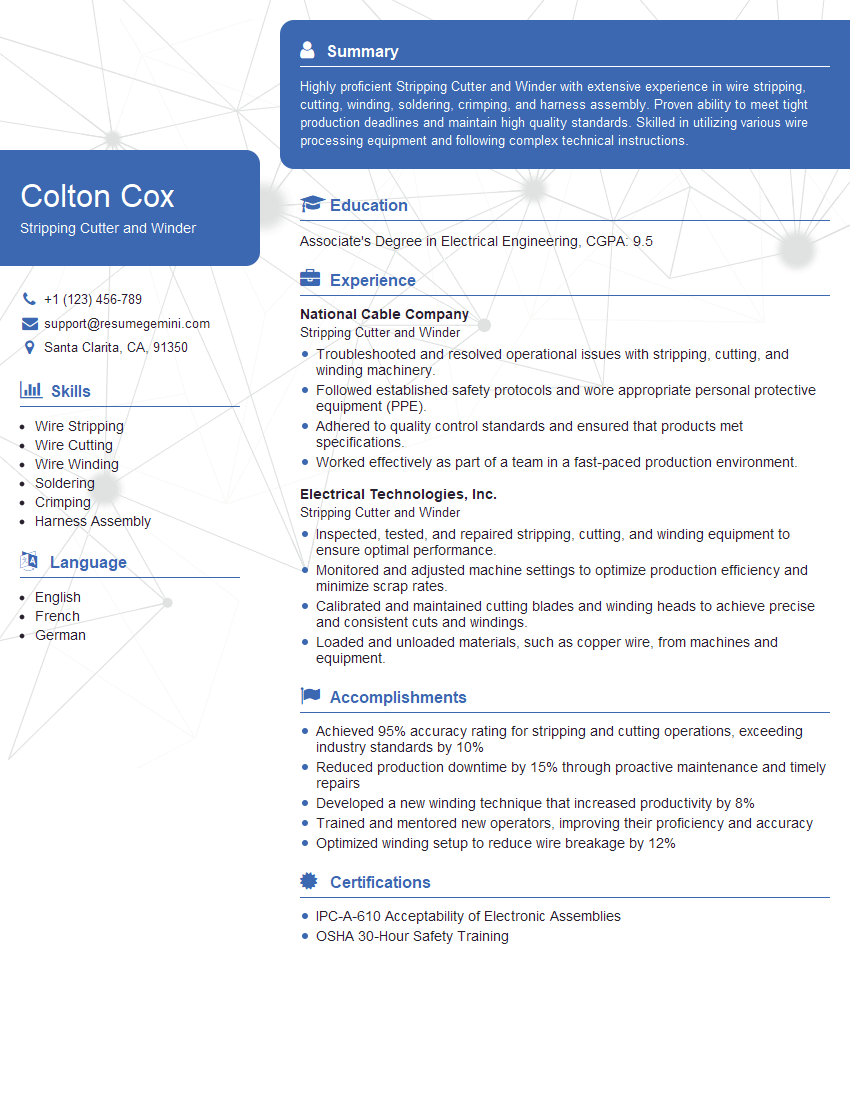

Colton Cox

Stripping Cutter and Winder

Summary

Highly proficient Stripping Cutter and Winder with extensive experience in wire stripping, cutting, winding, soldering, crimping, and harness assembly. Proven ability to meet tight production deadlines and maintain high quality standards. Skilled in utilizing various wire processing equipment and following complex technical instructions.

Education

Associate’s Degree in Electrical Engineering

August 2018

Skills

- Wire Stripping

- Wire Cutting

- Wire Winding

- Soldering

- Crimping

- Harness Assembly

Work Experience

Stripping Cutter and Winder

- Troubleshooted and resolved operational issues with stripping, cutting, and winding machinery.

- Followed established safety protocols and wore appropriate personal protective equipment (PPE).

- Adhered to quality control standards and ensured that products met specifications.

- Worked effectively as part of a team in a fast-paced production environment.

Stripping Cutter and Winder

- Inspected, tested, and repaired stripping, cutting, and winding equipment to ensure optimal performance.

- Monitored and adjusted machine settings to optimize production efficiency and minimize scrap rates.

- Calibrated and maintained cutting blades and winding heads to achieve precise and consistent cuts and windings.

- Loaded and unloaded materials, such as copper wire, from machines and equipment.

Accomplishments

- Achieved 95% accuracy rating for stripping and cutting operations, exceeding industry standards by 10%

- Reduced production downtime by 15% through proactive maintenance and timely repairs

- Developed a new winding technique that increased productivity by 8%

- Trained and mentored new operators, improving their proficiency and accuracy

- Optimized winding setup to reduce wire breakage by 12%

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- OSHA 30-Hour Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Stripping Cutter and Winder

- Quantify your experience and accomplishments whenever possible.

- Highlight any certifications or training programs you have completed.

- Include a portfolio or resume addendum that showcases your work.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Stripping Cutter and Winder Resume

- Strip a variety of wire gauges using a stripping machine, ensuring accurate and clean cuts.

- Cut wires to specified lengths using a wire cutting machine, maintaining precise dimensions.

- Wind wires onto coils or armatures using a winding machine, following specified winding patterns.

- Solder electrical connections using a soldering iron, ensuring proper joint strength and conductivity.

- Crimp terminals and connectors using a crimping tool, ensuring secure and reliable connections.

- Assemble wire harnesses according to design specifications, ensuring proper routing and termination.

- Inspect finished wire products for quality and accuracy, identifying and correcting any defects.

Frequently Asked Questions (FAQ’s) For Stripping Cutter and Winder

What is the primary role of a Stripping Cutter and Winder?

A Stripping Cutter and Winder performs various operations on electrical wires, including stripping insulation, cutting to length, winding onto coils, and assembling wire harnesses.

What are the essential skills for a Stripping Cutter and Winder?

Essential skills for a Stripping Cutter and Winder include wire stripping, cutting, winding, soldering, crimping, and harness assembly. Proficiency in operating wire processing equipment is also crucial.

Is it necessary to have a formal education to become a Stripping Cutter and Winder?

While a formal education in electrical engineering or a related field is beneficial, it is not always required. Many Stripping Cutters and Winders learn the necessary skills through on-the-job training and experience.

What are the career prospects for a Stripping Cutter and Winder?

Stripping Cutters and Winders can advance to supervisory or management positions within the manufacturing industry. With additional training or education, they may also pursue roles in electrical engineering or quality control.

How can I improve my chances of getting hired as a Stripping Cutter and Winder?

Obtain relevant certifications or training, build a strong resume that highlights your skills and experience, and practice your wire processing techniques to improve your accuracy and efficiency.

What is the average salary for a Stripping Cutter and Winder?

The average salary for a Stripping Cutter and Winder varies depending on experience, location, and industry. According to Salary.com, the average annual salary is around $35,000.