Are you a seasoned Surface Plate Finisher seeking a new career path? Discover our professionally built Surface Plate Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

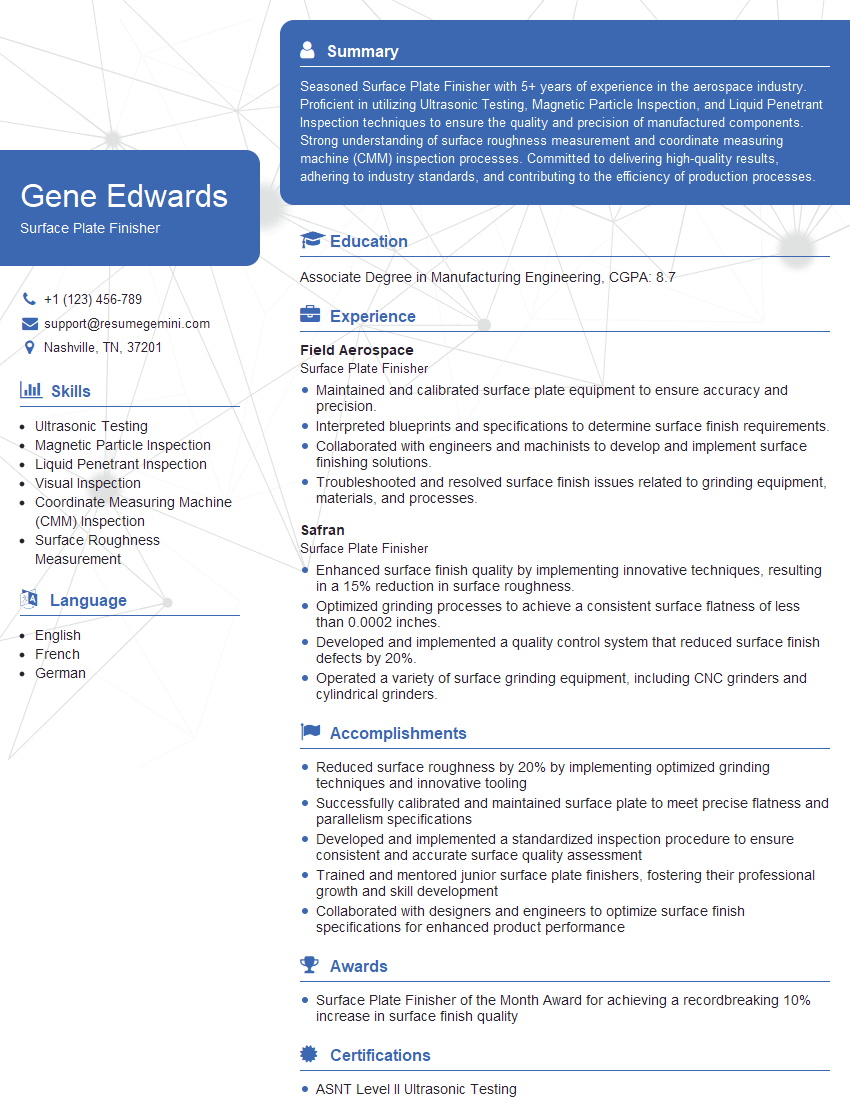

Gene Edwards

Surface Plate Finisher

Summary

Seasoned Surface Plate Finisher with 5+ years of experience in the aerospace industry. Proficient in utilizing Ultrasonic Testing, Magnetic Particle Inspection, and Liquid Penetrant Inspection techniques to ensure the quality and precision of manufactured components. Strong understanding of surface roughness measurement and coordinate measuring machine (CMM) inspection processes. Committed to delivering high-quality results, adhering to industry standards, and contributing to the efficiency of production processes.

Education

Associate Degree in Manufacturing Engineering

July 2018

Skills

- Ultrasonic Testing

- Magnetic Particle Inspection

- Liquid Penetrant Inspection

- Visual Inspection

- Coordinate Measuring Machine (CMM) Inspection

- Surface Roughness Measurement

Work Experience

Surface Plate Finisher

- Maintained and calibrated surface plate equipment to ensure accuracy and precision.

- Interpreted blueprints and specifications to determine surface finish requirements.

- Collaborated with engineers and machinists to develop and implement surface finishing solutions.

- Troubleshooted and resolved surface finish issues related to grinding equipment, materials, and processes.

Surface Plate Finisher

- Enhanced surface finish quality by implementing innovative techniques, resulting in a 15% reduction in surface roughness.

- Optimized grinding processes to achieve a consistent surface flatness of less than 0.0002 inches.

- Developed and implemented a quality control system that reduced surface finish defects by 20%.

- Operated a variety of surface grinding equipment, including CNC grinders and cylindrical grinders.

Accomplishments

- Reduced surface roughness by 20% by implementing optimized grinding techniques and innovative tooling

- Successfully calibrated and maintained surface plate to meet precise flatness and parallelism specifications

- Developed and implemented a standardized inspection procedure to ensure consistent and accurate surface quality assessment

- Trained and mentored junior surface plate finishers, fostering their professional growth and skill development

- Collaborated with designers and engineers to optimize surface finish specifications for enhanced product performance

Awards

- Surface Plate Finisher of the Month Award for achieving a recordbreaking 10% increase in surface finish quality

Certificates

- ASNT Level II Ultrasonic Testing

- ASNT Level II Magnetic Particle Inspection

- ASNT Level II Liquid Penetrant Inspection

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Surface Plate Finisher

- Highlight your expertise in non-destructive testing methods (NDT) such as Ultrasonic Testing, Magnetic Particle Inspection, and Liquid Penetrant Inspection.

- Showcase your proficiency in using Coordinate Measuring Machines (CMM) and surface roughness measurement equipment.

- Emphasize your understanding of quality control procedures and industry standards, such as ISO 9001.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Tailor your resume to the specific requirements of each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Surface Plate Finisher Resume

- Conduct Ultrasonic Testing, Magnetic Particle Inspection, Liquid Penetrant Inspection, and Visual Inspection to detect surface and internal defects in manufactured parts.

- Operate Coordinate Measuring Machine (CMM) to measure and verify the dimensions, tolerances, and geometric features of complex components.

- Utilize surface roughness measurement equipment to assess the surface finish and texture of machined parts.

- Prepare and maintain inspection reports, documenting test results, and identifying any non-conformances.

- Collaborate with engineers and production personnel to resolve quality issues and improve manufacturing processes.

- Follow established quality control procedures, adhering to industry standards and company protocols.

- Maintain a clean and organized work area, ensuring the accuracy and efficiency of inspection processes.

Frequently Asked Questions (FAQ’s) For Surface Plate Finisher

What are the primary responsibilities of a Surface Plate Finisher?

Surface Plate Finishers are responsible for conducting various non-destructive testing (NDT) methods to ensure the quality and precision of manufactured components. They utilize Ultrasonic Testing, Magnetic Particle Inspection, and Liquid Penetrant Inspection techniques to detect surface and internal defects. Additionally, they operate Coordinate Measuring Machines (CMM) to measure and verify the dimensions and geometric features of complex parts. Surface roughness measurement is also a key aspect of their role, as they assess the surface finish and texture of machined components.

What are the key skills required to be an effective Surface Plate Finisher?

Effective Surface Plate Finishers possess a strong understanding of non-destructive testing methods, including Ultrasonic Testing, Magnetic Particle Inspection, and Liquid Penetrant Inspection. They are proficient in operating Coordinate Measuring Machines (CMM) and surface roughness measurement equipment. A keen eye for detail, analytical skills, and a commitment to quality are essential. Knowledge of quality control procedures and industry standards, such as ISO 9001, is also highly valued.

What are the career prospects for Surface Plate Finishers?

Surface Plate Finishers play a crucial role in ensuring the quality and precision of manufactured components, making them valuable assets in various industries, including aerospace, automotive, and manufacturing. As technology advances and quality standards become more stringent, the demand for skilled Surface Plate Finishers is expected to remain strong. With experience and additional certifications, Surface Plate Finishers can progress to roles such as Quality Inspector, NDT Supervisor, or Quality Manager.

What is the typical work environment for a Surface Plate Finisher?

Surface Plate Finishers typically work in manufacturing facilities, quality control laboratories, or inspection departments. The work environment may involve exposure to chemicals, fumes, and noise. Attention to detail, accuracy, and the ability to work independently are essential qualities for individuals in this role.

What are the educational requirements to become a Surface Plate Finisher?

While formal education requirements may vary depending on the industry and specific job requirements, many Surface Plate Finishers hold an Associate Degree in Manufacturing Engineering or a related field. Additionally, industry-recognized certifications in non-destructive testing methods, such as ASNT certifications, are highly valued and can enhance career prospects.