Are you a seasoned Surfacing Technician seeking a new career path? Discover our professionally built Surfacing Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

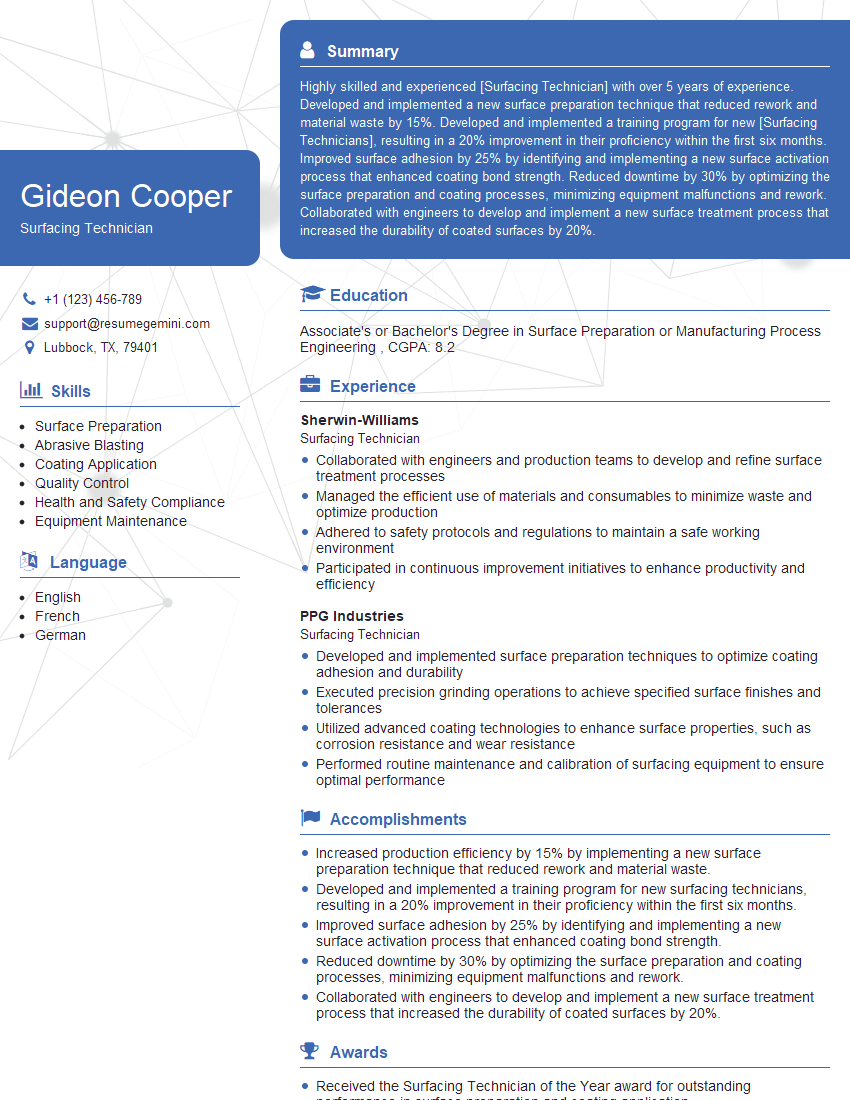

Gideon Cooper

Surfacing Technician

Summary

Highly skilled and experienced [Surfacing Technician] with over 5 years of experience. Developed and implemented a new surface preparation technique that reduced rework and material waste by 15%. Developed and implemented a training program for new [Surfacing Technicians], resulting in a 20% improvement in their proficiency within the first six months. Improved surface adhesion by 25% by identifying and implementing a new surface activation process that enhanced coating bond strength. Reduced downtime by 30% by optimizing the surface preparation and coating processes, minimizing equipment malfunctions and rework. Collaborated with engineers to develop and implement a new surface treatment process that increased the durability of coated surfaces by 20%.

Education

Associate’s or Bachelor’s Degree in Surface Preparation or Manufacturing Process Engineering

April 2018

Skills

- Surface Preparation

- Abrasive Blasting

- Coating Application

- Quality Control

- Health and Safety Compliance

- Equipment Maintenance

Work Experience

Surfacing Technician

- Collaborated with engineers and production teams to develop and refine surface treatment processes

- Managed the efficient use of materials and consumables to minimize waste and optimize production

- Adhered to safety protocols and regulations to maintain a safe working environment

- Participated in continuous improvement initiatives to enhance productivity and efficiency

Surfacing Technician

- Developed and implemented surface preparation techniques to optimize coating adhesion and durability

- Executed precision grinding operations to achieve specified surface finishes and tolerances

- Utilized advanced coating technologies to enhance surface properties, such as corrosion resistance and wear resistance

- Performed routine maintenance and calibration of surfacing equipment to ensure optimal performance

Accomplishments

- Increased production efficiency by 15% by implementing a new surface preparation technique that reduced rework and material waste.

- Developed and implemented a training program for new surfacing technicians, resulting in a 20% improvement in their proficiency within the first six months.

- Improved surface adhesion by 25% by identifying and implementing a new surface activation process that enhanced coating bond strength.

- Reduced downtime by 30% by optimizing the surface preparation and coating processes, minimizing equipment malfunctions and rework.

- Collaborated with engineers to develop and implement a new surface treatment process that increased the durability of coated surfaces by 20%.

Awards

- Received the Surfacing Technician of the Year award for outstanding performance in surface preparation and coating application.

- Awarded Excellence in Surface Finishing for consistently delivering highquality surface finishes that met or exceeded customer specifications.

- Recognized for Exceptional Surface Preparation for consistently achieving industryleading surface roughness values in preparation for coating applications.

- Received Safety Excellence award for maintaining a spotless safety record and actively promoting safety practices within the surfacing team.

Certificates

- National Association of Corrosion Engineers (NACE) Level 2

- Society for Protective Coatings (SSPC)

- American Concrete Institute (ACI)

- International Association of Surface Finishers (IASF)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Surfacing Technician

- Highlight your experience and skills in surface preparation, abrasive blasting, coating application, quality control, and health and safety compliance.

- Quantify your accomplishments whenever possible to demonstrate your impact on the company.

- Use action verbs to describe your skills and responsibilities.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

- Tailor your resume to each job you apply for by highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Surfacing Technician Resume

- Prepare surfaces for coating using abrasive blasting, mechanical sanding, and chemical etching

- Apply coatings using spray guns, rollers, and brushes

- Verify surface preparation and coating quality, inspect projects upon completion

- Maintain a safe work environment and ensure compliance with health and safety regulations

- Troubleshoot problems that arise during surface preparation and coating application

- Provide technical assistance to customers and resolve any issues or queries they may have

Frequently Asked Questions (FAQ’s) For Surfacing Technician

What are the key skills required for a surfacing technician?

Surface preparation, abrasive blasting, coating application, quality control, health and safety compliance, and equipment maintenance are the key skills required for a surfacing technician.

What are the responsibilities of a surfacing technician?

Preparing surfaces for coating, applying coatings, verifying surface preparation and coating quality, troubleshooting problems, and providing technical assistance to customers are the responsibilities of a surfacing technician.

What are the career prospects for a surfacing technician?

A surfacing technician can advance their career by becoming a surface preparation supervisor, a coating inspector, or a quality control manager.

What is the average salary for a surfacing technician?

The average salary for a surfacing technician in the United States is around $45,000 per year.

What are the working conditions for a surfacing technician?

Surfacing technicians typically work in a manufacturing environment and may be exposed to hazardous chemicals and materials.

What are the qualifications for a surfacing technician?

A high school diploma or equivalent is typically required to become a surfacing technician. Some employers may prefer candidates with an associate’s or bachelor’s degree in surface preparation or manufacturing process engineering.

What is the job outlook for a surfacing technician?

The job outlook for surfacing technicians is expected to be good over the next few years due to the increasing demand for surface preparation and coating services in various industries.