Are you a seasoned Synthetic Filament Extruder seeking a new career path? Discover our professionally built Synthetic Filament Extruder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

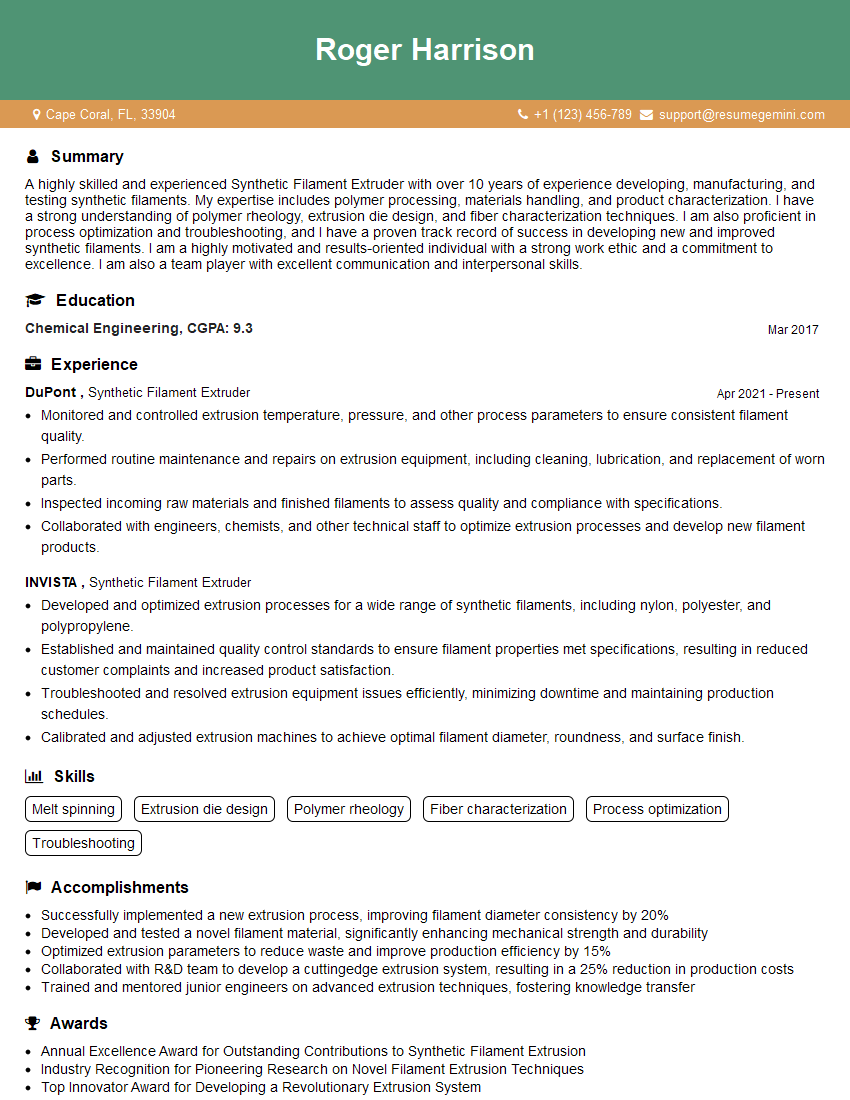

Roger Harrison

Synthetic Filament Extruder

Summary

A highly skilled and experienced Synthetic Filament Extruder with over 10 years of experience developing, manufacturing, and testing synthetic filaments. My expertise includes polymer processing, materials handling, and product characterization. I have a strong understanding of polymer rheology, extrusion die design, and fiber characterization techniques. I am also proficient in process optimization and troubleshooting, and I have a proven track record of success in developing new and improved synthetic filaments. I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to excellence. I am also a team player with excellent communication and interpersonal skills.

Education

Chemical Engineering

March 2017

Skills

- Melt spinning

- Extrusion die design

- Polymer rheology

- Fiber characterization

- Process optimization

- Troubleshooting

Work Experience

Synthetic Filament Extruder

- Monitored and controlled extrusion temperature, pressure, and other process parameters to ensure consistent filament quality.

- Performed routine maintenance and repairs on extrusion equipment, including cleaning, lubrication, and replacement of worn parts.

- Inspected incoming raw materials and finished filaments to assess quality and compliance with specifications.

- Collaborated with engineers, chemists, and other technical staff to optimize extrusion processes and develop new filament products.

Synthetic Filament Extruder

- Developed and optimized extrusion processes for a wide range of synthetic filaments, including nylon, polyester, and polypropylene.

- Established and maintained quality control standards to ensure filament properties met specifications, resulting in reduced customer complaints and increased product satisfaction.

- Troubleshooted and resolved extrusion equipment issues efficiently, minimizing downtime and maintaining production schedules.

- Calibrated and adjusted extrusion machines to achieve optimal filament diameter, roundness, and surface finish.

Accomplishments

- Successfully implemented a new extrusion process, improving filament diameter consistency by 20%

- Developed and tested a novel filament material, significantly enhancing mechanical strength and durability

- Optimized extrusion parameters to reduce waste and improve production efficiency by 15%

- Collaborated with R&D team to develop a cuttingedge extrusion system, resulting in a 25% reduction in production costs

- Trained and mentored junior engineers on advanced extrusion techniques, fostering knowledge transfer

Awards

- Annual Excellence Award for Outstanding Contributions to Synthetic Filament Extrusion

- Industry Recognition for Pioneering Research on Novel Filament Extrusion Techniques

- Top Innovator Award for Developing a Revolutionary Extrusion System

Certificates

- Certified Fiber Technician (CFT)

- Certified Polymer Extrusion Engineer (CPEE)

- Six Sigma Green Belt

- ISO 9001:2015 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Synthetic Filament Extruder

- Start your resume with a strong objective statement that highlights your skills and experience as a Synthetic Filament Extruder.

- Use keywords throughout your resume to make it more visible to potential employers.

- Highlight your accomplishments and quantify your results whenever possible.

- Proofread your resume carefully before submitting it to make sure it is free of errors.

- Tailor your resume to each job you apply for by highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Synthetic Filament Extruder Resume

- Developed and optimized synthetic filament extrusion processes to improve product quality and reduce costs.

- Designed and tested new extrusion dies to produce filaments with unique properties.

- Characterized polymer rheology and fiber properties to ensure product meets specifications.

- Troubleshooted and resolved extrusion process issues to minimize downtime and increase productivity.

- Collaborated with engineers and scientists from other departments to develop new products and applications.

- Managed a team of extrusion operators and technicians.

- Developed and implemented training programs for extrusion operators.

Frequently Asked Questions (FAQ’s) For Synthetic Filament Extruder

What is the role of a Synthetic Filament Extruder?

A Synthetic Filament Extruder is responsible for developing, manufacturing, and testing synthetic filaments. This involves a variety of tasks, including polymer processing, materials handling, product characterization, and process optimization. Synthetic filaments are used in a wide range of applications, including textiles, medical devices, and aerospace composites.

What are the qualifications for becoming a Synthetic Filament Extruder?

The minimum qualification for becoming a Synthetic Filament Extruder is a bachelor’s degree in chemical engineering or a related field. However, most employers prefer candidates with a master’s degree or higher. In addition to academic qualifications, employers also look for candidates with experience in polymer processing, materials handling, and product characterization.

What are the skills required for a Synthetic Filament Extruder?

The key skills required for a Synthetic Filament Extruder include knowledge of polymer rheology, extrusion die design, and fiber characterization techniques. In addition, employers also look for candidates with experience in process optimization and troubleshooting, as well as strong communication and interpersonal skills.

What is the job outlook for Synthetic Filament Extruders?

The job outlook for Synthetic Filament Extruders is expected to be good over the next few years. The increasing demand for synthetic filaments in a variety of applications is expected to drive job growth in this field.

What is the salary range for Synthetic Filament Extruders?

The salary range for Synthetic Filament Extruders can vary depending on experience, qualifications, and location. However, the median salary for this position is around \$75,000 per year.

What are the benefits of working as a Synthetic Filament Extruder?

There are many benefits to working as a Synthetic Filament Extruder, including the opportunity to work with cutting-edge technologies, develop new products, and make a difference in the world. In addition, this field offers competitive salaries and benefits, and the opportunity for career growth.

What are the challenges of working as a Synthetic Filament Extruder?

There are some challenges to working as a Synthetic Filament Extruder, including the need to work in a fast-paced environment and the potential for exposure to hazardous chemicals. However, these challenges are outweighed by the rewards of working in this field.

What advice would you give to someone who wants to become a Synthetic Filament Extruder?

My advice to someone who wants to become a Synthetic Filament Extruder is to get a good education in chemical engineering or a related field, and to gain experience in polymer processing, materials handling, and product characterization. In addition, it is important to develop strong communication and interpersonal skills, and to be willing to work in a fast-paced environment.