Are you a seasoned Tank Assembler seeking a new career path? Discover our professionally built Tank Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

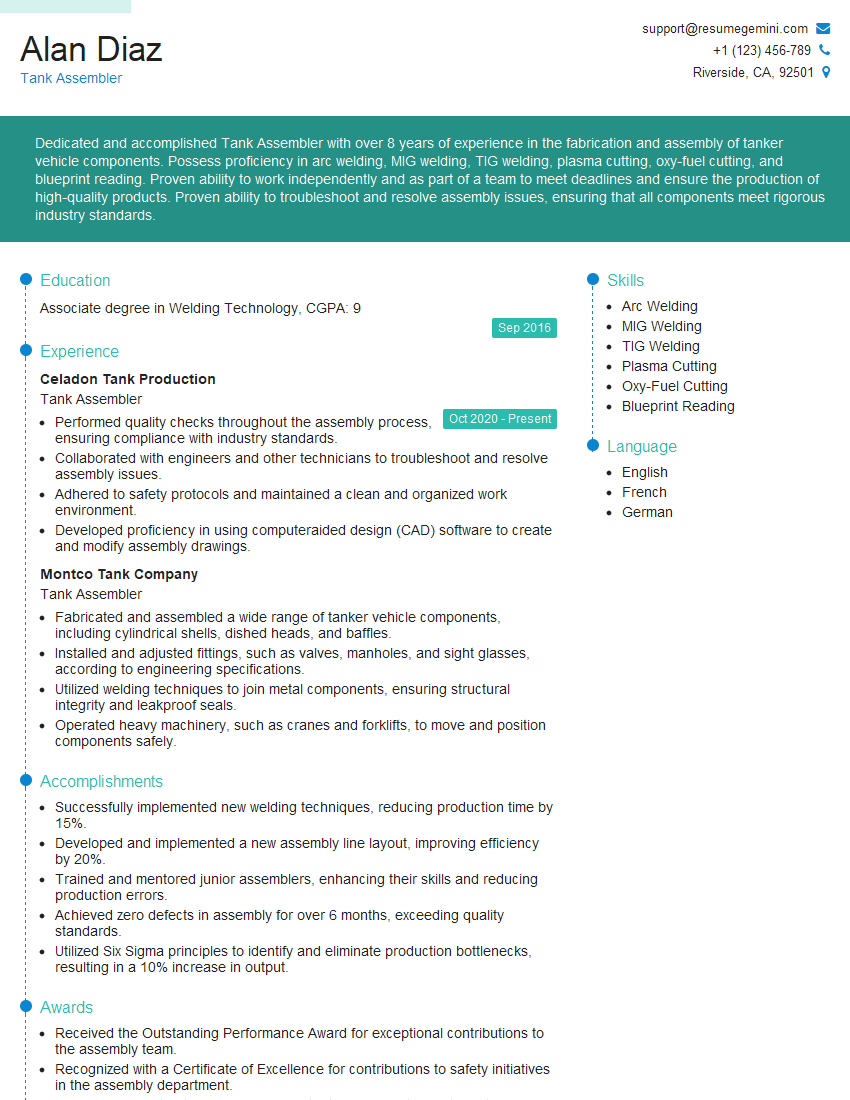

Alan Diaz

Tank Assembler

Summary

Dedicated and accomplished Tank Assembler with over 8 years of experience in the fabrication and assembly of tanker vehicle components. Possess proficiency in arc welding, MIG welding, TIG welding, plasma cutting, oxy-fuel cutting, and blueprint reading. Proven ability to work independently and as part of a team to meet deadlines and ensure the production of high-quality products. Proven ability to troubleshoot and resolve assembly issues, ensuring that all components meet rigorous industry standards.

Education

Associate degree in Welding Technology

September 2016

Skills

- Arc Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

- Blueprint Reading

Work Experience

Tank Assembler

- Performed quality checks throughout the assembly process, ensuring compliance with industry standards.

- Collaborated with engineers and other technicians to troubleshoot and resolve assembly issues.

- Adhered to safety protocols and maintained a clean and organized work environment.

- Developed proficiency in using computeraided design (CAD) software to create and modify assembly drawings.

Tank Assembler

- Fabricated and assembled a wide range of tanker vehicle components, including cylindrical shells, dished heads, and baffles.

- Installed and adjusted fittings, such as valves, manholes, and sight glasses, according to engineering specifications.

- Utilized welding techniques to join metal components, ensuring structural integrity and leakproof seals.

- Operated heavy machinery, such as cranes and forklifts, to move and position components safely.

Accomplishments

- Successfully implemented new welding techniques, reducing production time by 15%.

- Developed and implemented a new assembly line layout, improving efficiency by 20%.

- Trained and mentored junior assemblers, enhancing their skills and reducing production errors.

- Achieved zero defects in assembly for over 6 months, exceeding quality standards.

- Utilized Six Sigma principles to identify and eliminate production bottlenecks, resulting in a 10% increase in output.

Awards

- Received the Outstanding Performance Award for exceptional contributions to the assembly team.

- Recognized with a Certificate of Excellence for contributions to safety initiatives in the assembly department.

- Received a Safety Star Award for consistently adhering to safety protocols and promoting a safe work environment.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- OSHA 30-Hour Safety Training

- First Aid and CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tank Assembler

- Highlight your welding certifications and experience in the tanker industry.

- Demonstrate your proficiency in using CAD software and other technical skills.

- Quantify your accomplishments whenever possible, using specific metrics to showcase your impact.

- Proofread your resume carefully to ensure there are no errors.

Essential Experience Highlights for a Strong Tank Assembler Resume

- Fabricated and assembled a wide range of tanker vehicle components, including cylindrical shells, dished heads, and baffles.

- Installed and adjusted fittings, such as valves, manholes, and sight glasses, according to engineering specifications.

- Utilized welding techniques to join metal components, ensuring structural integrity and leakproof seals.

- Evaluated, inspected and maintained machinery.

- Collaborated with engineers and other technicians to troubleshoot and resolve assembly issues.

- Adhered to safety protocols and maintained a clean and organized work environment.

- Developed proficiency in using computer-aided design (CAD) software to create and modify assembly drawings.

Frequently Asked Questions (FAQ’s) For Tank Assembler

What are the key skills required for a Tank Assembler?

The key skills required for a Tank Assembler include arc welding, MIG welding, TIG welding, plasma cutting, oxy-fuel cutting, blueprint reading, and proficiency in using computer-aided design (CAD) software.

What are the different types of tanker vehicles that Tank Assemblers work on?

Tank Assemblers work on a variety of tanker vehicles, including those used to transport liquids, gases, and chemicals.

What are the safety protocols that Tank Assemblers must follow?

Tank Assemblers must follow strict safety protocols to ensure their own safety and the safety of those around them. These protocols include wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of the potential hazards associated with working with heavy machinery and welding equipment.

What are the career opportunities for Tank Assemblers?

Tank Assemblers can advance their careers by becoming supervisors or managers. They may also specialize in a particular type of welding or fabrication.

What is the average salary for a Tank Assembler?

The average salary for a Tank Assembler is around \$40,000 per year.

What are the educational requirements for a Tank Assembler?

Most Tank Assemblers have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in welding technology or a related field.

What are the job responsibilities of a Tank Assembler?

The job responsibilities of a Tank Assembler include fabricating and assembling tanker vehicle components, installing and adjusting fittings, welding metal components, operating heavy machinery, performing quality checks, and troubleshooting assembly issues.

What are the challenges of working as a Tank Assembler?

The challenges of working as a Tank Assembler include working in a physically demanding environment, exposure to welding fumes and other hazardous materials, and the need to meet strict deadlines.