Are you a seasoned Tap and Die Maker Technician seeking a new career path? Discover our professionally built Tap and Die Maker Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

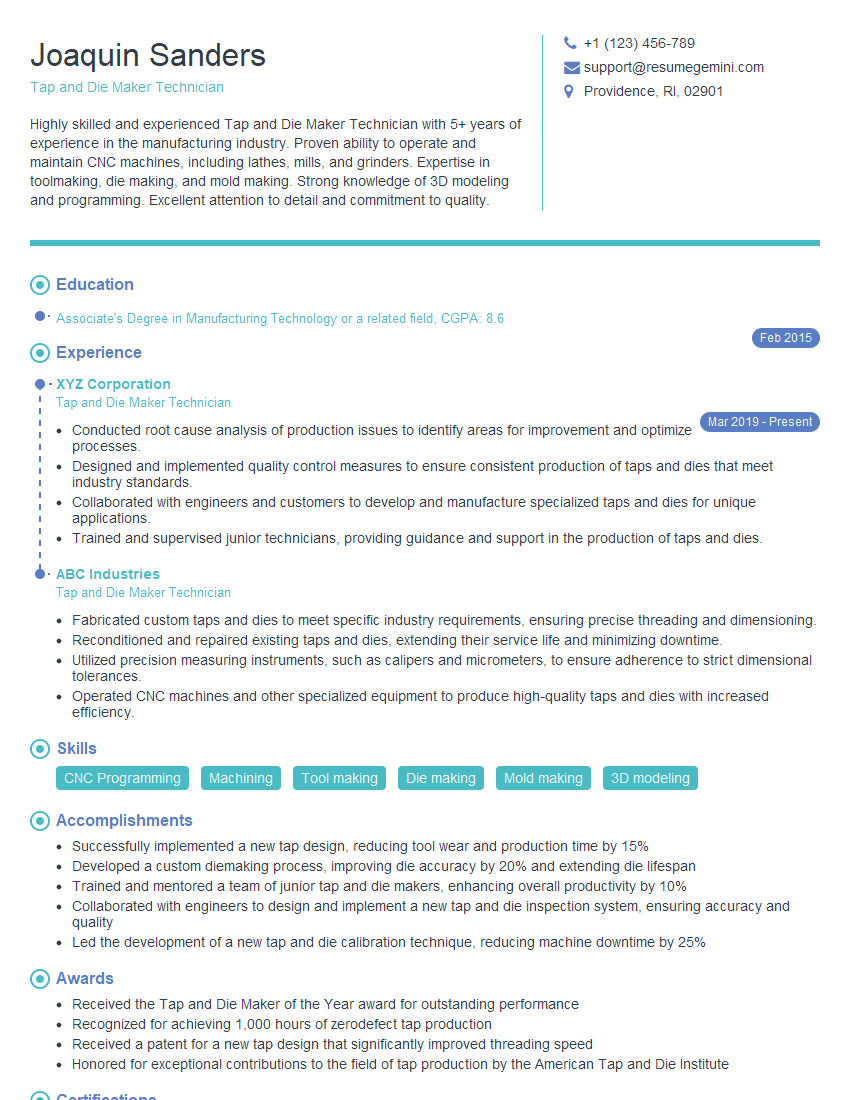

Joaquin Sanders

Tap and Die Maker Technician

Summary

Highly skilled and experienced Tap and Die Maker Technician with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain CNC machines, including lathes, mills, and grinders. Expertise in toolmaking, die making, and mold making. Strong knowledge of 3D modeling and programming. Excellent attention to detail and commitment to quality.

Education

Associate’s Degree in Manufacturing Technology or a related field

February 2015

Skills

- CNC Programming

- Machining

- Tool making

- Die making

- Mold making

- 3D modeling

Work Experience

Tap and Die Maker Technician

- Conducted root cause analysis of production issues to identify areas for improvement and optimize processes.

- Designed and implemented quality control measures to ensure consistent production of taps and dies that meet industry standards.

- Collaborated with engineers and customers to develop and manufacture specialized taps and dies for unique applications.

- Trained and supervised junior technicians, providing guidance and support in the production of taps and dies.

Tap and Die Maker Technician

- Fabricated custom taps and dies to meet specific industry requirements, ensuring precise threading and dimensioning.

- Reconditioned and repaired existing taps and dies, extending their service life and minimizing downtime.

- Utilized precision measuring instruments, such as calipers and micrometers, to ensure adherence to strict dimensional tolerances.

- Operated CNC machines and other specialized equipment to produce high-quality taps and dies with increased efficiency.

Accomplishments

- Successfully implemented a new tap design, reducing tool wear and production time by 15%

- Developed a custom diemaking process, improving die accuracy by 20% and extending die lifespan

- Trained and mentored a team of junior tap and die makers, enhancing overall productivity by 10%

- Collaborated with engineers to design and implement a new tap and die inspection system, ensuring accuracy and quality

- Led the development of a new tap and die calibration technique, reducing machine downtime by 25%

Awards

- Received the Tap and Die Maker of the Year award for outstanding performance

- Recognized for achieving 1,000 hours of zerodefect tap production

- Received a patent for a new tap design that significantly improved threading speed

- Honored for exceptional contributions to the field of tap production by the American Tap and Die Institute

Certificates

- Certified Tool and Die Maker (CTDM)

- Certified Mold Maker (CMM)

- CNC Programming Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tap and Die Maker Technician

- Highlight your experience and skills in operating and maintaining CNC machines.

- Showcase your expertise in toolmaking, die making, and mold making.

- Demonstrate your knowledge of 3D modeling and programming.

- Emphasize your attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Tap and Die Maker Technician Resume

- Operate and maintain CNC machines, including lathes, mills, and grinders, to produce precision parts and components.

- Set up and adjust tooling, fixtures, and workpieces to ensure accuracy and efficiency.

- Inspect and measure finished parts to ensure they meet specifications and quality standards.

- Troubleshoot and resolve machine malfunctions and production issues to minimize downtime.

- Maintain a clean and organized work area, adhering to safety regulations and best practices.

- Collaborate with engineers and other team members to develop and improve manufacturing processes.

- Stay updated on the latest industry trends and technologies related to tap and die making.

Frequently Asked Questions (FAQ’s) For Tap and Die Maker Technician

What is a Tap and Die Maker Technician?

A Tap and Die Maker Technician is a skilled professional who operates and maintains CNC machines to produce precision parts and components. They have expertise in toolmaking, die making, and mold making, and are responsible for setting up and adjusting tooling, fixtures, and workpieces to ensure accuracy and efficiency.

What are the qualifications for a Tap and Die Maker Technician?

Most Tap and Die Maker Technicians have an Associate’s Degree in Manufacturing Technology or a related field, along with several years of experience in the manufacturing industry. They should be proficient in operating and maintaining CNC machines, have expertise in toolmaking, die making, and mold making, and be familiar with 3D modeling and programming.

What are the key responsibilities of a Tap and Die Maker Technician?

The key responsibilities of a Tap and Die Maker Technician include operating and maintaining CNC machines, setting up and adjusting tooling, fixtures, and workpieces, inspecting and measuring finished parts, troubleshooting and resolving machine malfunctions and production issues, maintaining a clean and organized work area, and collaborating with engineers and other team members to develop and improve manufacturing processes.

What are the career prospects for a Tap and Die Maker Technician?

Tap and Die Maker Technicians are in high demand in the manufacturing industry, and their skills are essential for the production of precision parts and components. With experience and training, they can advance to supervisory or management positions, or specialize in a particular area of manufacturing, such as toolmaking, die making, or mold making.

What are the earning prospects for a Tap and Die Maker Technician?

The earning prospects for a Tap and Die Maker Technician vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC Machinists was $48,070 in May 2021, with the top 10% earning more than $78,030.

What are the challenges faced by Tap and Die Maker Technicians?

Tap and Die Maker Technicians face several challenges in their work, including the need to keep up with the latest industry trends and technologies, the need to work with precision and accuracy, and the potential for exposure to hazardous materials and machinery.