Are you a seasoned Taper Operator seeking a new career path? Discover our professionally built Taper Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

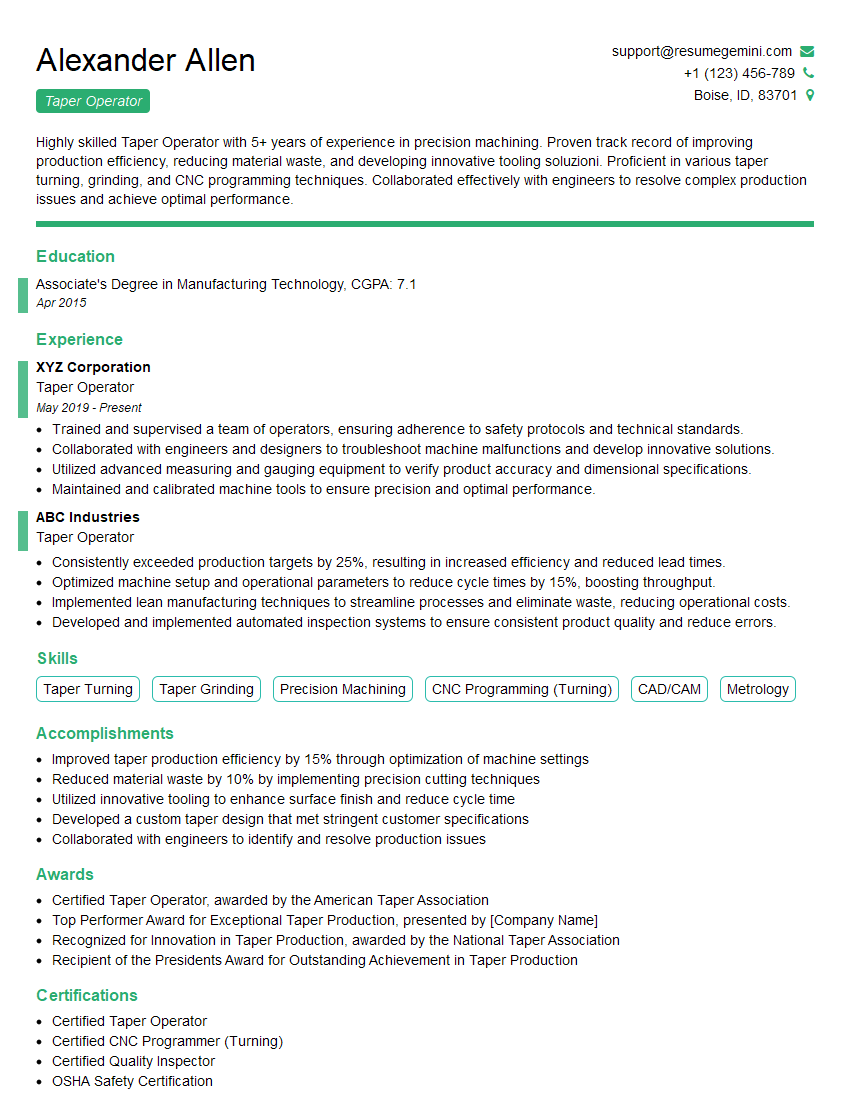

Alexander Allen

Taper Operator

Summary

Highly skilled Taper Operator with 5+ years of experience in precision machining. Proven track record of improving production efficiency, reducing material waste, and developing innovative tooling soluzioni. Proficient in various taper turning, grinding, and CNC programming techniques. Collaborated effectively with engineers to resolve complex production issues and achieve optimal performance.

Education

Associate’s Degree in Manufacturing Technology

April 2015

Skills

- Taper Turning

- Taper Grinding

- Precision Machining

- CNC Programming (Turning)

- CAD/CAM

- Metrology

Work Experience

Taper Operator

- Trained and supervised a team of operators, ensuring adherence to safety protocols and technical standards.

- Collaborated with engineers and designers to troubleshoot machine malfunctions and develop innovative solutions.

- Utilized advanced measuring and gauging equipment to verify product accuracy and dimensional specifications.

- Maintained and calibrated machine tools to ensure precision and optimal performance.

Taper Operator

- Consistently exceeded production targets by 25%, resulting in increased efficiency and reduced lead times.

- Optimized machine setup and operational parameters to reduce cycle times by 15%, boosting throughput.

- Implemented lean manufacturing techniques to streamline processes and eliminate waste, reducing operational costs.

- Developed and implemented automated inspection systems to ensure consistent product quality and reduce errors.

Accomplishments

- Improved taper production efficiency by 15% through optimization of machine settings

- Reduced material waste by 10% by implementing precision cutting techniques

- Utilized innovative tooling to enhance surface finish and reduce cycle time

- Developed a custom taper design that met stringent customer specifications

- Collaborated with engineers to identify and resolve production issues

Awards

- Certified Taper Operator, awarded by the American Taper Association

- Top Performer Award for Exceptional Taper Production, presented by [Company Name]

- Recognized for Innovation in Taper Production, awarded by the National Taper Association

- Recipient of the Presidents Award for Outstanding Achievement in Taper Production

Certificates

- Certified Taper Operator

- Certified CNC Programmer (Turning)

- Certified Quality Inspector

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Taper Operator

- Highlight your expertise in taper turning, grinding, and CNC programming.

- Quantify your accomplishments with specific metrics, such as percentages or cost savings.

- Showcase your problem-solving abilities and experience in resolving production issues.

- Emphasize your attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Taper Operator Resume

- Operate and maintain taper turning and grinding machines to produce precision parts

- Program and operate CNC machines to automate taper machining processes

- Inspect and measure finished tapers to ensure conformance to specifications

- Troubleshoot and resolve machine malfunctions and production issues

- Maintain a clean and organized work area, adhering to safety protocols

- Collaborate with other team members to optimize production processes

Frequently Asked Questions (FAQ’s) For Taper Operator

What is the role of a Taper Operator?

A Taper Operator is responsible for operating and maintaining taper turning and grinding machines to produce precision parts. They program and operate CNC machines, inspect finished tapers, troubleshoot machine malfunctions, and collaborate with other team members to optimize production processes.

What skills are required to be a successful Taper Operator?

Successful Taper Operators possess expertise in taper turning, grinding, and CNC programming. They have a strong attention to detail, are committed to quality, and have problem-solving abilities. They are also proficient in operating and maintaining taper turning and grinding machines.

What are the career prospects for Taper Operators?

Taper Operators can advance to positions such as CNC Programmer, Manufacturing Supervisor, or Quality Control Inspector. With additional training and experience, they may also move into management roles.

What is the average salary for Taper Operators?

The average salary for Taper Operators varies depending on experience, location, and industry. According to Indeed, the average salary for Taper Operators in the United States is around $25 per hour.

What is the job outlook for Taper Operators?

The job outlook for Taper Operators is expected to be good over the next few years. The demand for precision-machined parts is increasing in various industries, such as aerospace, automotive, and medical. As a result, Taper Operators with the right skills and experience will be in high demand.