Are you a seasoned Thermal Cutting Machine Operator seeking a new career path? Discover our professionally built Thermal Cutting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

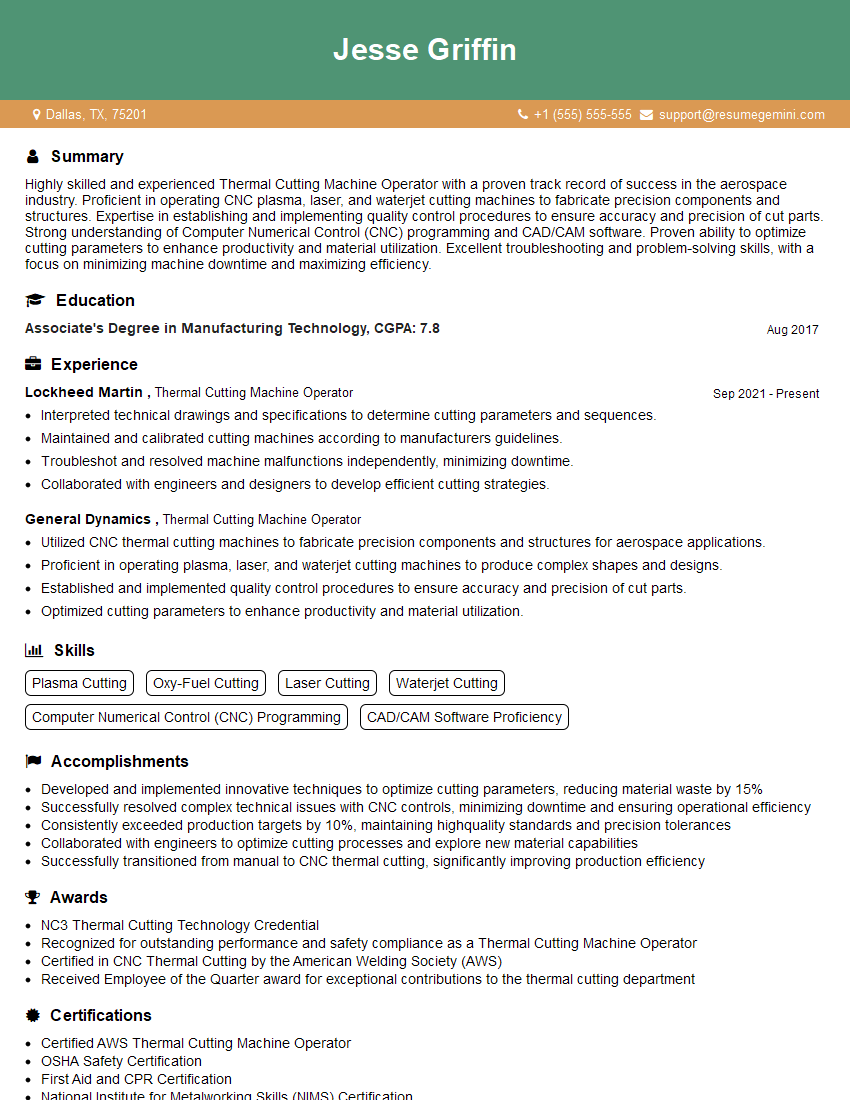

Jesse Griffin

Thermal Cutting Machine Operator

Summary

Highly skilled and experienced Thermal Cutting Machine Operator with a proven track record of success in the aerospace industry. Proficient in operating CNC plasma, laser, and waterjet cutting machines to fabricate precision components and structures. Expertise in establishing and implementing quality control procedures to ensure accuracy and precision of cut parts. Strong understanding of Computer Numerical Control (CNC) programming and CAD/CAM software. Proven ability to optimize cutting parameters to enhance productivity and material utilization. Excellent troubleshooting and problem-solving skills, with a focus on minimizing machine downtime and maximizing efficiency.

Education

Associate’s Degree in Manufacturing Technology

August 2017

Skills

- Plasma Cutting

- Oxy-Fuel Cutting

- Laser Cutting

- Waterjet Cutting

- Computer Numerical Control (CNC) Programming

- CAD/CAM Software Proficiency

Work Experience

Thermal Cutting Machine Operator

- Interpreted technical drawings and specifications to determine cutting parameters and sequences.

- Maintained and calibrated cutting machines according to manufacturers guidelines.

- Troubleshot and resolved machine malfunctions independently, minimizing downtime.

- Collaborated with engineers and designers to develop efficient cutting strategies.

Thermal Cutting Machine Operator

- Utilized CNC thermal cutting machines to fabricate precision components and structures for aerospace applications.

- Proficient in operating plasma, laser, and waterjet cutting machines to produce complex shapes and designs.

- Established and implemented quality control procedures to ensure accuracy and precision of cut parts.

- Optimized cutting parameters to enhance productivity and material utilization.

Accomplishments

- Developed and implemented innovative techniques to optimize cutting parameters, reducing material waste by 15%

- Successfully resolved complex technical issues with CNC controls, minimizing downtime and ensuring operational efficiency

- Consistently exceeded production targets by 10%, maintaining highquality standards and precision tolerances

- Collaborated with engineers to optimize cutting processes and explore new material capabilities

- Successfully transitioned from manual to CNC thermal cutting, significantly improving production efficiency

Awards

- NC3 Thermal Cutting Technology Credential

- Recognized for outstanding performance and safety compliance as a Thermal Cutting Machine Operator

- Certified in CNC Thermal Cutting by the American Welding Society (AWS)

- Received Employee of the Quarter award for exceptional contributions to the thermal cutting department

Certificates

- Certified AWS Thermal Cutting Machine Operator

- OSHA Safety Certification

- First Aid and CPR Certification

- National Institute for Metalworking Skills (NIMS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermal Cutting Machine Operator

- Highlight your experience and skills in operating CNC thermal cutting machines, including plasma, laser, and waterjet cutting.

- Showcase your knowledge of quality control procedures and your ability to ensure accuracy and precision in cut parts.

- Emphasize your expertise in optimizing cutting parameters to enhance productivity and material utilization.

- Include any experience in interpreting technical drawings and specifications to determine cutting parameters and sequences.

Essential Experience Highlights for a Strong Thermal Cutting Machine Operator Resume

- Operate CNC thermal cutting machines to fabricate precision components and structures for aerospace applications.

- Proficient in operating plasma, laser, and waterjet cutting machines to produce complex shapes and designs.

- Establish and implement quality control procedures to ensure accuracy and precision of cut parts.

- Optimize cutting parameters to enhance productivity and material utilization.

- Interpret technical drawings and specifications to determine cutting parameters and sequences.

- Maintain and calibrate cutting machines according to manufacturers guidelines.

- Troubleshoot and resolve machine malfunctions independently, minimizing downtime.

Frequently Asked Questions (FAQ’s) For Thermal Cutting Machine Operator

What are the primary responsibilities of a Thermal Cutting Machine Operator?

The primary responsibilities of a Thermal Cutting Machine Operator include operating CNC thermal cutting machines, establishing and implementing quality control procedures, optimizing cutting parameters, interpreting technical drawings and specifications, maintaining and calibrating cutting machines, and troubleshooting and resolving machine malfunctions.

What are the essential skills required to be a successful Thermal Cutting Machine Operator?

Essential skills for a Thermal Cutting Machine Operator include proficiency in operating CNC thermal cutting machines, knowledge of quality control procedures, expertise in optimizing cutting parameters, ability to interpret technical drawings and specifications, and experience in maintaining and calibrating cutting machines.

What are the key qualities that employers look for in a Thermal Cutting Machine Operator?

Employers seek Thermal Cutting Machine Operators with strong technical skills, a commitment to quality and precision, a focus on productivity and efficiency, and a proactive approach to problem-solving.

What is the job outlook for Thermal Cutting Machine Operators?

The job outlook for Thermal Cutting Machine Operators is expected to be positive in the coming years, driven by the growing demand for precision-cut components in various industries, including aerospace, automotive, and manufacturing.

What are the career advancement opportunities for Thermal Cutting Machine Operators?

Thermal Cutting Machine Operators can advance their careers by developing specialized skills in specific cutting technologies, such as plasma, laser, or waterjet cutting. They can also move into supervisory or management roles within the manufacturing industry.