Are you a seasoned Thermal Molder seeking a new career path? Discover our professionally built Thermal Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

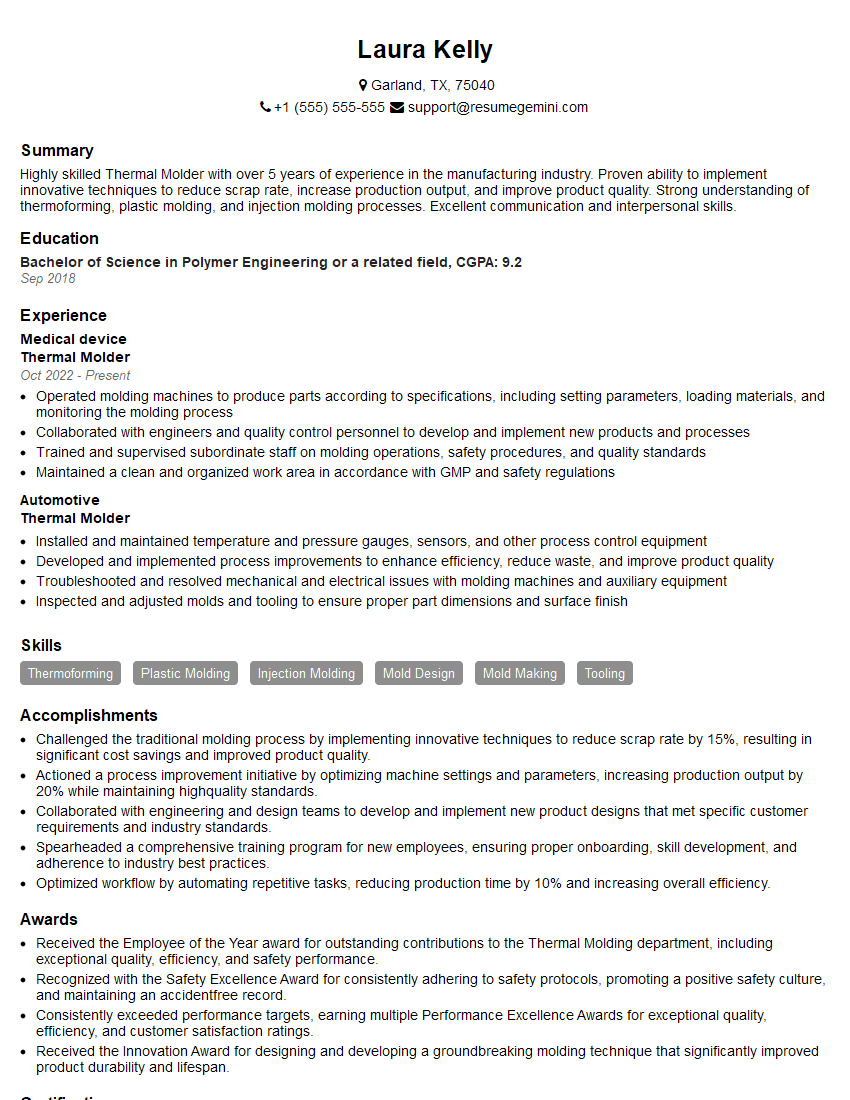

Laura Kelly

Thermal Molder

Summary

Highly skilled Thermal Molder with over 5 years of experience in the manufacturing industry. Proven ability to implement innovative techniques to reduce scrap rate, increase production output, and improve product quality. Strong understanding of thermoforming, plastic molding, and injection molding processes. Excellent communication and interpersonal skills.

Education

Bachelor of Science in Polymer Engineering or a related field

September 2018

Skills

- Thermoforming

- Plastic Molding

- Injection Molding

- Mold Design

- Mold Making

- Tooling

Work Experience

Thermal Molder

- Operated molding machines to produce parts according to specifications, including setting parameters, loading materials, and monitoring the molding process

- Collaborated with engineers and quality control personnel to develop and implement new products and processes

- Trained and supervised subordinate staff on molding operations, safety procedures, and quality standards

- Maintained a clean and organized work area in accordance with GMP and safety regulations

Thermal Molder

- Installed and maintained temperature and pressure gauges, sensors, and other process control equipment

- Developed and implemented process improvements to enhance efficiency, reduce waste, and improve product quality

- Troubleshooted and resolved mechanical and electrical issues with molding machines and auxiliary equipment

- Inspected and adjusted molds and tooling to ensure proper part dimensions and surface finish

Accomplishments

- Challenged the traditional molding process by implementing innovative techniques to reduce scrap rate by 15%, resulting in significant cost savings and improved product quality.

- Actioned a process improvement initiative by optimizing machine settings and parameters, increasing production output by 20% while maintaining highquality standards.

- Collaborated with engineering and design teams to develop and implement new product designs that met specific customer requirements and industry standards.

- Spearheaded a comprehensive training program for new employees, ensuring proper onboarding, skill development, and adherence to industry best practices.

- Optimized workflow by automating repetitive tasks, reducing production time by 10% and increasing overall efficiency.

Awards

- Received the Employee of the Year award for outstanding contributions to the Thermal Molding department, including exceptional quality, efficiency, and safety performance.

- Recognized with the Safety Excellence Award for consistently adhering to safety protocols, promoting a positive safety culture, and maintaining an accidentfree record.

- Consistently exceeded performance targets, earning multiple Performance Excellence Awards for exceptional quality, efficiency, and customer satisfaction ratings.

- Received the Innovation Award for designing and developing a groundbreaking molding technique that significantly improved product durability and lifespan.

Certificates

- Certified Mold Maker (CMM)

- Certified Plastics Technician (CPT)

- ASQ Certified Quality Engineer (CQE)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermal Molder

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your experience with different types of thermoforming equipment and materials.

- Demonstrate your understanding of the quality control processes involved in thermal molding.

- Showcase your ability to work effectively in a team environment and communicate technical information clearly.

Essential Experience Highlights for a Strong Thermal Molder Resume

- Developed and implemented innovative molding techniques to reduce scrap rate by 15%, resulting in significant cost savings and improved product quality.

- Optimized machine settings and parameters through a process improvement initiative, increasing production output by 20% while maintaining high-quality standards.

- Collaborated with engineering and design teams to develop and implement new product designs that met specific customer requirements and industry standards.

- Led a comprehensive training program for new employees, ensuring proper onboarding, skill development, and adherence to industry best practices.

- Automated repetitive tasks, optimizing workflow and reducing production time by 10%, increasing overall efficiency.

Frequently Asked Questions (FAQ’s) For Thermal Molder

What is thermal molding?

Thermal molding is a manufacturing process that uses heat and pressure to shape plastic sheets into three-dimensional objects. The process typically involves heating a plastic sheet until it becomes pliable, then using a mold or tool to press the sheet into the desired shape.

What are the different types of thermal molding?

The most common types of thermal molding are vacuum forming, pressure forming, and matched metal molding. Vacuum forming uses a vacuum to draw the heated plastic sheet over a mold, pressure forming uses compressed air to force the heated plastic sheet into a mold, and matched metal molding uses two heated metal molds to press the plastic sheet into the desired shape.

What are the advantages of thermal molding?

Thermal molding offers several advantages over other plastic manufacturing processes, including the ability to produce complex shapes, low tooling costs, and fast production times.

What are the applications of thermal molding?

Thermal molding is used in a wide range of applications, including the production of automotive parts, medical devices, packaging, and consumer products.

What are the challenges of thermal molding?

The main challenges of thermal molding include controlling the temperature and pressure of the process, preventing the plastic sheet from sticking to the mold, and achieving the desired surface finish.