Are you a seasoned Threading Machine Operator seeking a new career path? Discover our professionally built Threading Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

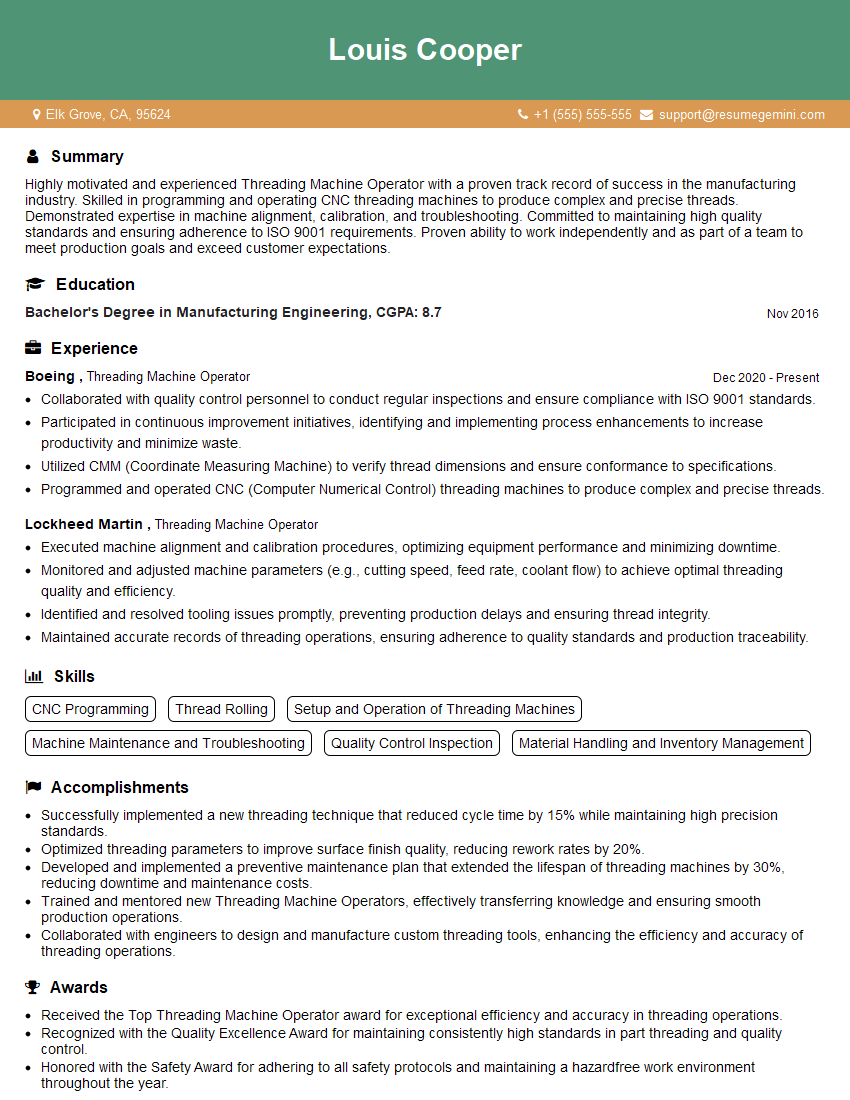

Louis Cooper

Threading Machine Operator

Summary

Highly motivated and experienced Threading Machine Operator with a proven track record of success in the manufacturing industry. Skilled in programming and operating CNC threading machines to produce complex and precise threads. Demonstrated expertise in machine alignment, calibration, and troubleshooting. Committed to maintaining high quality standards and ensuring adherence to ISO 9001 requirements. Proven ability to work independently and as part of a team to meet production goals and exceed customer expectations.

Education

Bachelor’s Degree in Manufacturing Engineering

November 2016

Skills

- CNC Programming

- Thread Rolling

- Setup and Operation of Threading Machines

- Machine Maintenance and Troubleshooting

- Quality Control Inspection

- Material Handling and Inventory Management

Work Experience

Threading Machine Operator

- Collaborated with quality control personnel to conduct regular inspections and ensure compliance with ISO 9001 standards.

- Participated in continuous improvement initiatives, identifying and implementing process enhancements to increase productivity and minimize waste.

- Utilized CMM (Coordinate Measuring Machine) to verify thread dimensions and ensure conformance to specifications.

- Programmed and operated CNC (Computer Numerical Control) threading machines to produce complex and precise threads.

Threading Machine Operator

- Executed machine alignment and calibration procedures, optimizing equipment performance and minimizing downtime.

- Monitored and adjusted machine parameters (e.g., cutting speed, feed rate, coolant flow) to achieve optimal threading quality and efficiency.

- Identified and resolved tooling issues promptly, preventing production delays and ensuring thread integrity.

- Maintained accurate records of threading operations, ensuring adherence to quality standards and production traceability.

Accomplishments

- Successfully implemented a new threading technique that reduced cycle time by 15% while maintaining high precision standards.

- Optimized threading parameters to improve surface finish quality, reducing rework rates by 20%.

- Developed and implemented a preventive maintenance plan that extended the lifespan of threading machines by 30%, reducing downtime and maintenance costs.

- Trained and mentored new Threading Machine Operators, effectively transferring knowledge and ensuring smooth production operations.

- Collaborated with engineers to design and manufacture custom threading tools, enhancing the efficiency and accuracy of threading operations.

Awards

- Received the Top Threading Machine Operator award for exceptional efficiency and accuracy in threading operations.

- Recognized with the Quality Excellence Award for maintaining consistently high standards in part threading and quality control.

- Honored with the Safety Award for adhering to all safety protocols and maintaining a hazardfree work environment throughout the year.

Certificates

- CNC Machinist Certification

- Thread Rolling Machine Operator Certification

- Quality Control Inspector Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Threading Machine Operator

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated a threading machine,” say “I operated a threading machine and increased production by 15%”.

- Highlight your skills and experience in operating CNC threading machines. This is a specialized skill that is in high demand in the manufacturing industry.

- Showcase your knowledge of quality control standards and procedures. This is essential for ensuring that the threads you produce meet customer specifications.

- Emphasize your ability to work independently and as part of a team. This is important for any manufacturing role.

- Proofread your resume carefully before submitting it. A well-written resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Threading Machine Operator Resume

- Program and operate CNC threading machines to produce threads that meet specified dimensions and tolerances.

- Set up and calibrate threading machines, ensuring optimal performance and minimizing downtime.

- Monitor machine parameters and make adjustments as needed to achieve optimal threading quality and efficiency.

- Identify and resolve tooling issues promptly, preventing production delays and ensuring thread integrity.

- Maintain accurate records of threading operations, ensuring adherence to quality standards and production traceability.

- Collaborate with quality control personnel to conduct regular inspections and ensure compliance with ISO 9001 standards.

Frequently Asked Questions (FAQ’s) For Threading Machine Operator

What is a Threading Machine Operator?

A Threading Machine Operator is responsible for operating and maintaining threading machines. These machines are used to create threads on metal parts. Threading Machine Operators must be able to read blueprints and follow instructions, as well as have a good understanding of machining processes.

What are the duties of a Threading Machine Operator?

The duties of a Threading Machine Operator include: setting up and operating threading machines, monitoring machine parameters, identifying and resolving tooling issues, maintaining accurate records of threading operations, and collaborating with quality control personnel to ensure compliance with ISO 9001 standards.

What are the qualifications for a Threading Machine Operator?

The qualifications for a Threading Machine Operator typically include a high school diploma or equivalent, as well as experience in operating CNC threading machines. Some employers may also require candidates to have a college degree in manufacturing engineering or a related field.

What is the work environment of a Threading Machine Operator?

Threading Machine Operators typically work in manufacturing environments. They may be exposed to noise, dust, and other hazards. They must also be able to work independently and as part of a team.

What is the salary of a Threading Machine Operator?

The salary of a Threading Machine Operator varies depending on experience, location, and employer. According to Indeed, the average salary for a Threading Machine Operator in the United States is $20.00 per hour.

What is the job outlook for Threading Machine Operators?

The job outlook for Threading Machine Operators is expected to be good over the next few years. As manufacturing continues to grow, there will be a need for skilled Threading Machine Operators.