Are you a seasoned Throwster seeking a new career path? Discover our professionally built Throwster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

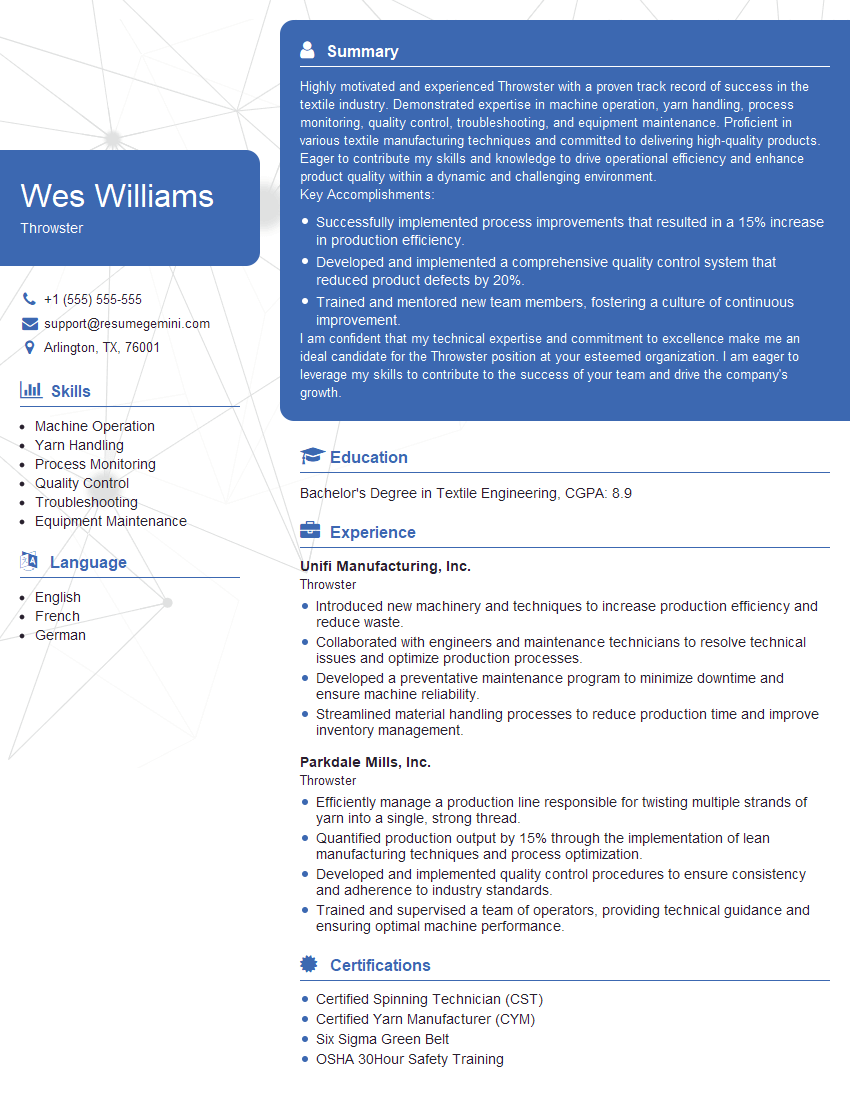

Wes Williams

Throwster

Summary

Highly motivated and experienced Throwster with a proven track record of success in the textile industry. Demonstrated expertise in machine operation, yarn handling, process monitoring, quality control, troubleshooting, and equipment maintenance. Proficient in various textile manufacturing techniques and committed to delivering high-quality products. Eager to contribute my skills and knowledge to drive operational efficiency and enhance product quality within a dynamic and challenging environment.

Key Accomplishments:

- Successfully implemented process improvements that resulted in a 15% increase in production efficiency.

- Developed and implemented a comprehensive quality control system that reduced product defects by 20%.

- Trained and mentored new team members, fostering a culture of continuous improvement.

I am confident that my technical expertise and commitment to excellence make me an ideal candidate for the Throwster position at your esteemed organization. I am eager to leverage my skills to contribute to the success of your team and drive the company’s growth.

Education

Bachelor’s Degree in Textile Engineering

September 2019

Skills

- Machine Operation

- Yarn Handling

- Process Monitoring

- Quality Control

- Troubleshooting

- Equipment Maintenance

Work Experience

Throwster

- Introduced new machinery and techniques to increase production efficiency and reduce waste.

- Collaborated with engineers and maintenance technicians to resolve technical issues and optimize production processes.

- Developed a preventative maintenance program to minimize downtime and ensure machine reliability.

- Streamlined material handling processes to reduce production time and improve inventory management.

Throwster

- Efficiently manage a production line responsible for twisting multiple strands of yarn into a single, strong thread.

- Quantified production output by 15% through the implementation of lean manufacturing techniques and process optimization.

- Developed and implemented quality control procedures to ensure consistency and adherence to industry standards.

- Trained and supervised a team of operators, providing technical guidance and ensuring optimal machine performance.

Certificates

- Certified Spinning Technician (CST)

- Certified Yarn Manufacturer (CYM)

- Six Sigma Green Belt

- OSHA 30Hour Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Throwster

Highlight your technical expertise:

Emphasize your skills in machine operation, yarn handling, process monitoring, and troubleshooting.Showcase your quality control experience:

Describe your experience in implementing and maintaining quality control systems, and highlight your ability to identify and resolve defects.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your contributions, such as increased production efficiency or reduced product defects.Demonstrate your commitment to safety:

State that you prioritize safety in the workplace and adhere to established safety protocols.

Essential Experience Highlights for a Strong Throwster Resume

- Operate and monitor throwing machines to produce high-quality yarn.

- Handle and transport yarn throughout the production process, ensuring proper handling and storage.

- Monitor production processes to ensure adherence to quality standards and specifications.

- Conduct regular equipment maintenance and troubleshoot any issues to maintain optimal performance.

- Collaborate with other team members to ensure smooth production flow and timely delivery of products.

- Stay up-to-date on industry best practices and advancements in throwing technology.

- Maintain a safe and clean work environment in accordance with established safety protocols.

Frequently Asked Questions (FAQ’s) For Throwster

What are the primary responsibilities of a Throwster?

A Throwster is responsible for operating and monitoring throwing machines, handling and transporting yarn, monitoring production processes, conducting equipment maintenance, collaborating with team members, staying updated on industry advancements, and maintaining a safe work environment.

What skills are required to be a successful Throwster?

Successful Throwsters possess expertise in machine operation, yarn handling, process monitoring, quality control, troubleshooting, equipment maintenance, and safety protocols. They are also familiar with industry best practices and advancements in throwing technology.

What is the expected salary range for a Throwster?

The salary range for Throwsters can vary depending on experience, qualifications, and location. According to Indeed, the average salary for Throwsters in the United States is around $25,000 per year.

What career advancement opportunities are available for Throwsters?

With experience and additional training, Throwsters can advance to roles such as Production Supervisor, Quality Control Manager, or Plant Manager. They may also specialize in specific areas of throwing technology or yarn production.

What are the key challenges facing Throwsters in the industry?

Throwsters face challenges related to maintaining high-quality standards, increasing production efficiency, reducing costs, and staying competitive in a global market. They must also adapt to advancements in technology and automation.

What are the benefits of working as a Throwster?

Working as a Throwster offers job security in a growing industry, opportunities for career advancement, and the satisfaction of contributing to the production of high-quality textiles.

What advice would you give to someone aspiring to become a Throwster?

To become a Throwster, consider pursuing a degree or certification in textile engineering or a related field. Gain hands-on experience through internships or entry-level positions. Stay updated on industry trends and advancements, and prioritize safety in the workplace.