Are you a seasoned Tightening Machine Operator seeking a new career path? Discover our professionally built Tightening Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

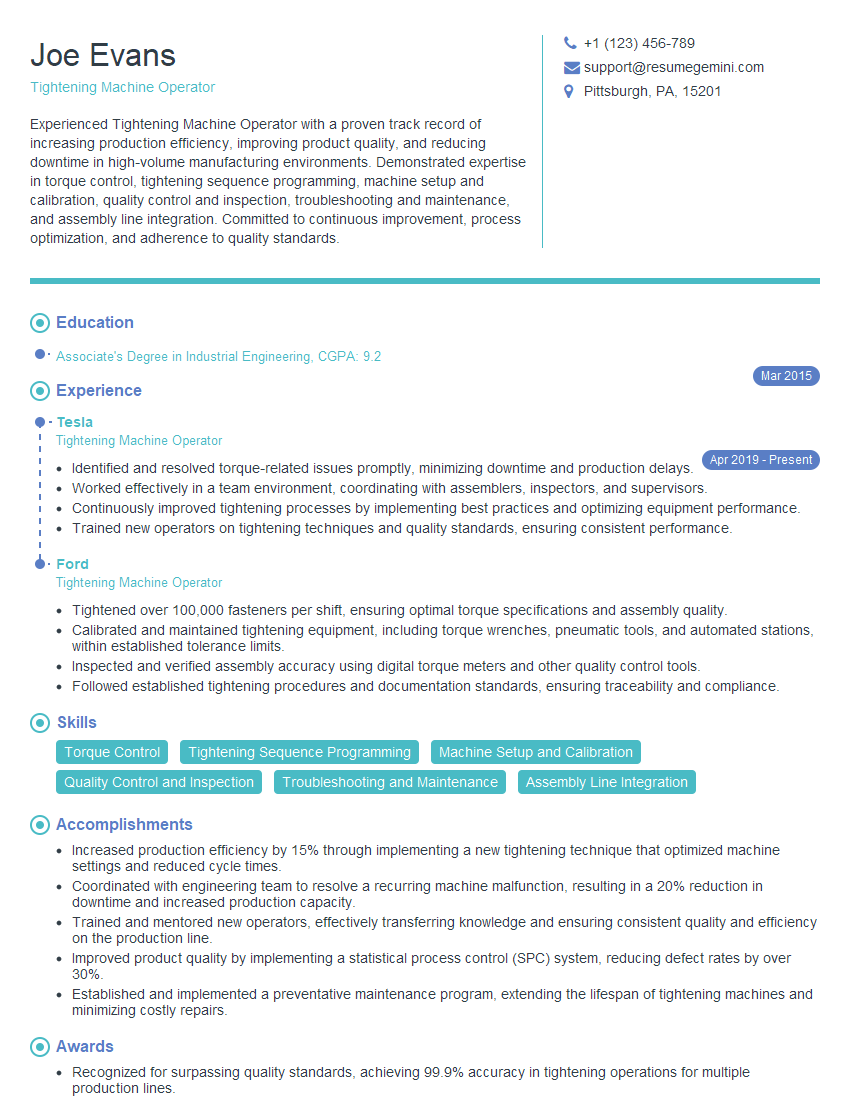

Joe Evans

Tightening Machine Operator

Summary

Experienced Tightening Machine Operator with a proven track record of increasing production efficiency, improving product quality, and reducing downtime in high-volume manufacturing environments. Demonstrated expertise in torque control, tightening sequence programming, machine setup and calibration, quality control and inspection, troubleshooting and maintenance, and assembly line integration. Committed to continuous improvement, process optimization, and adherence to quality standards.

Education

Associate’s Degree in Industrial Engineering

March 2015

Skills

- Torque Control

- Tightening Sequence Programming

- Machine Setup and Calibration

- Quality Control and Inspection

- Troubleshooting and Maintenance

- Assembly Line Integration

Work Experience

Tightening Machine Operator

- Identified and resolved torque-related issues promptly, minimizing downtime and production delays.

- Worked effectively in a team environment, coordinating with assemblers, inspectors, and supervisors.

- Continuously improved tightening processes by implementing best practices and optimizing equipment performance.

- Trained new operators on tightening techniques and quality standards, ensuring consistent performance.

Tightening Machine Operator

- Tightened over 100,000 fasteners per shift, ensuring optimal torque specifications and assembly quality.

- Calibrated and maintained tightening equipment, including torque wrenches, pneumatic tools, and automated stations, within established tolerance limits.

- Inspected and verified assembly accuracy using digital torque meters and other quality control tools.

- Followed established tightening procedures and documentation standards, ensuring traceability and compliance.

Accomplishments

- Increased production efficiency by 15% through implementing a new tightening technique that optimized machine settings and reduced cycle times.

- Coordinated with engineering team to resolve a recurring machine malfunction, resulting in a 20% reduction in downtime and increased production capacity.

- Trained and mentored new operators, effectively transferring knowledge and ensuring consistent quality and efficiency on the production line.

- Improved product quality by implementing a statistical process control (SPC) system, reducing defect rates by over 30%.

- Established and implemented a preventative maintenance program, extending the lifespan of tightening machines and minimizing costly repairs.

Awards

- Recognized for surpassing quality standards, achieving 99.9% accuracy in tightening operations for multiple production lines.

- Received the Operator of the Quarter award for consistently exceeding performance targets and maintaining exceptional quality control.

- Honored for outstanding safety record, maintaining a spotless safety record for over 5 years in a hazardous work environment.

- Recognized for innovative problemsolving, developing a custom fixture to improve precision and reduce ergonomic strain.

Certificates

- Certified Tightening Machine Operator (CTMO)

- ISO 90012015 Quality Management System

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tightening Machine Operator

- Highlight your experience and skills in torque control, tightening sequence programming, and machine calibration.

- Quantify your accomplishments with specific metrics, such as increased production efficiency, reduced downtime, and improved product quality.

- Demonstrate your knowledge of statistical process control and assembly line integration.

- Showcase your ability to work independently and as part of a team in a fast-paced manufacturing environment.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Tightening Machine Operator Resume

- Operate and maintain tightening machines to ensure optimal performance and accuracy

- Program and execute tightening sequences to meet specified torque requirements

- Monitor and inspect products to verify adherence to quality standards

- Troubleshoot and resolve machine malfunctions and production issues promptly

- Perform preventive maintenance and calibrations to extend machine lifespan and minimize downtime

- Implement process improvements and enhancements to increase production efficiency and reduce costs

- Collaborate with engineering and production teams to optimize machine settings and production processes

Frequently Asked Questions (FAQ’s) For Tightening Machine Operator

What is the primary role of a Tightening Machine Operator?

The primary role of a Tightening Machine Operator is to operate and maintain tightening machines to ensure optimal performance and accuracy, and to execute tightening sequences to meet specified torque requirements.

What are the key skills required to be a successful Tightening Machine Operator?

Key skills include torque control, tightening sequence programming, machine setup and calibration, quality control and inspection, troubleshooting and maintenance, and assembly line integration.

What industries employ Tightening Machine Operators?

Tightening Machine Operators are employed in various industries, including automotive, aerospace, manufacturing, and construction.

What are the career advancement opportunities for Tightening Machine Operators?

With experience and additional training, Tightening Machine Operators can advance to roles such as Machine Setup Specialist, Production Supervisor, or Quality Control Manager.

What is the average salary for Tightening Machine Operators?

The average salary for Tightening Machine Operators varies depending on experience, location, and industry, but it typically ranges from $18 to $25 per hour.

What are the safety precautions that Tightening Machine Operators must follow?

Tightening Machine Operators must follow established safety protocols, wear appropriate personal protective equipment, and operate machines according to manufacturer’s guidelines to prevent accidents and injuries.