Are you a seasoned Tin Cutter seeking a new career path? Discover our professionally built Tin Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

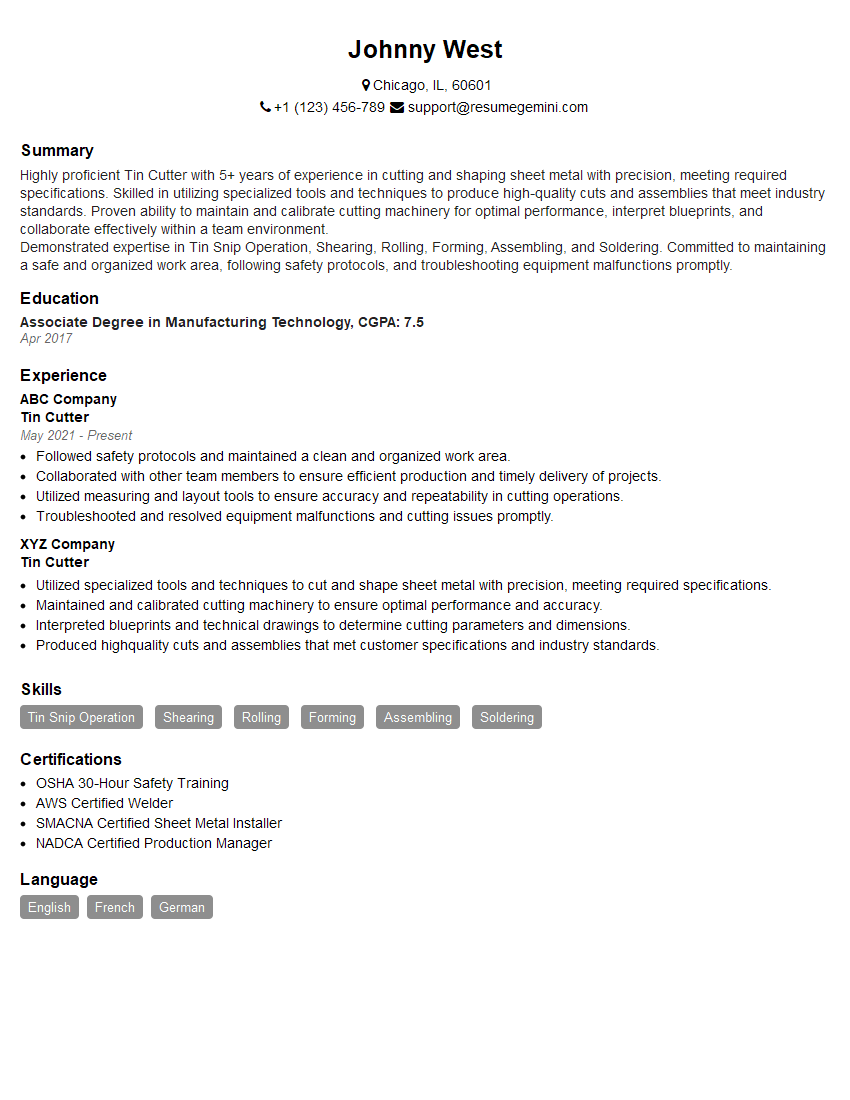

Johnny West

Tin Cutter

Summary

Highly proficient Tin Cutter with 5+ years of experience in cutting and shaping sheet metal with precision, meeting required specifications. Skilled in utilizing specialized tools and techniques to produce high-quality cuts and assemblies that meet industry standards. Proven ability to maintain and calibrate cutting machinery for optimal performance, interpret blueprints, and collaborate effectively within a team environment.

Demonstrated expertise in Tin Snip Operation, Shearing, Rolling, Forming, Assembling, and Soldering. Committed to maintaining a safe and organized work area, following safety protocols, and troubleshooting equipment malfunctions promptly.

Education

Associate Degree in Manufacturing Technology

April 2017

Skills

- Tin Snip Operation

- Shearing

- Rolling

- Forming

- Assembling

- Soldering

Work Experience

Tin Cutter

- Followed safety protocols and maintained a clean and organized work area.

- Collaborated with other team members to ensure efficient production and timely delivery of projects.

- Utilized measuring and layout tools to ensure accuracy and repeatability in cutting operations.

- Troubleshooted and resolved equipment malfunctions and cutting issues promptly.

Tin Cutter

- Utilized specialized tools and techniques to cut and shape sheet metal with precision, meeting required specifications.

- Maintained and calibrated cutting machinery to ensure optimal performance and accuracy.

- Interpreted blueprints and technical drawings to determine cutting parameters and dimensions.

- Produced highquality cuts and assemblies that met customer specifications and industry standards.

Certificates

- OSHA 30-Hour Safety Training

- AWS Certified Welder

- SMACNA Certified Sheet Metal Installer

- NADCA Certified Production Manager

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tin Cutter

Highlight relevant skills and experience:

Emphasize your proficiency in Tin Snip Operation, Shearing, Rolling, Forming, Assembling, and Soldering.Showcase your technical abilities:

Quantify your accomplishments and demonstrate your understanding of cutting parameters, dimensions, and industry standards.Demonstrate a commitment to quality and safety:

Describe your attention to detail, adherence to safety protocols, and ability to maintain a clean and organized work area.Use action verbs:

Start your bullet points with strong action verbs that convey your responsibilities and achievements.Proofread carefully:

Ensure your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Tin Cutter Resume

- Utilized specialized tools and techniques to cut and shape sheet metal with precision, meeting required specifications.

- Maintained and calibrated cutting machinery to ensure optimal performance and accuracy.

- Interpreted blueprints and technical drawings to determine cutting parameters and dimensions.

- Produced high-quality cuts and assemblies that met customer specifications and industry standards.

- Followed safety protocols and maintained a clean and organized work area.

- Collaborated with other team members to ensure efficient production and timely delivery of projects.

- Utilized measuring and layout tools to ensure accuracy and repeatability in cutting operations.

- Troubleshooted and resolved equipment malfunctions and cutting issues promptly.

Frequently Asked Questions (FAQ’s) For Tin Cutter

What are the primary responsibilities of a Tin Cutter?

Tin Cutters are responsible for cutting and shaping sheet metal using specialized tools and techniques, interpreting blueprints, maintaining cutting machinery, and ensuring the quality and accuracy of their work.

What qualifications are required to become a Tin Cutter?

Typically, an Associate Degree in Manufacturing Technology or a related field is required, along with hands-on experience in cutting and shaping sheet metal.

What are the key skills for a Tin Cutter?

Essential skills include Tin Snip Operation, Shearing, Rolling, Forming, Assembling, and Soldering, as well as proficiency in using measuring and layout tools.

What industries employ Tin Cutters?

Tin Cutters find employment in various industries, including manufacturing, construction, automotive, and HVAC.

What is the job outlook for Tin Cutters?

The job outlook for Tin Cutters is expected to be stable in the coming years due to the ongoing demand for skilled tradespeople in the manufacturing and construction industries.

What are the earning prospects for Tin Cutters?

Earning prospects for Tin Cutters vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers, which includes Tin Cutters, was around $50,000 in May 2021.

What are the benefits of working as a Tin Cutter?

Benefits may include competitive salaries, opportunities for career advancement, job security, and the satisfaction of working in a skilled trade.