Are you a seasoned Tin Pourer seeking a new career path? Discover our professionally built Tin Pourer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

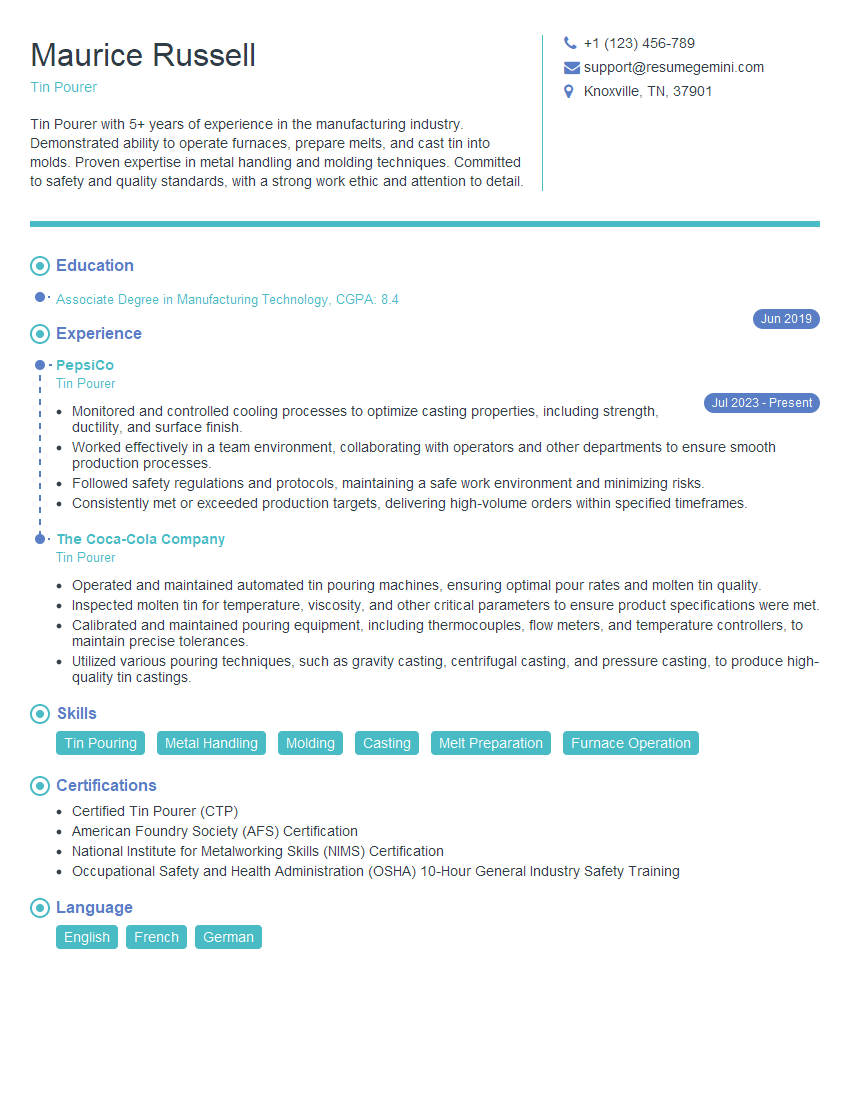

Maurice Russell

Tin Pourer

Summary

Tin Pourer with 5+ years of experience in the manufacturing industry. Demonstrated ability to operate furnaces, prepare melts, and cast tin into molds. Proven expertise in metal handling and molding techniques. Committed to safety and quality standards, with a strong work ethic and attention to detail.

Education

Associate Degree in Manufacturing Technology

June 2019

Skills

- Tin Pouring

- Metal Handling

- Molding

- Casting

- Melt Preparation

- Furnace Operation

Work Experience

Tin Pourer

- Monitored and controlled cooling processes to optimize casting properties, including strength, ductility, and surface finish.

- Worked effectively in a team environment, collaborating with operators and other departments to ensure smooth production processes.

- Followed safety regulations and protocols, maintaining a safe work environment and minimizing risks.

- Consistently met or exceeded production targets, delivering high-volume orders within specified timeframes.

Tin Pourer

- Operated and maintained automated tin pouring machines, ensuring optimal pour rates and molten tin quality.

- Inspected molten tin for temperature, viscosity, and other critical parameters to ensure product specifications were met.

- Calibrated and maintained pouring equipment, including thermocouples, flow meters, and temperature controllers, to maintain precise tolerances.

- Utilized various pouring techniques, such as gravity casting, centrifugal casting, and pressure casting, to produce high-quality tin castings.

Certificates

- Certified Tin Pourer (CTP)

- American Foundry Society (AFS) Certification

- National Institute for Metalworking Skills (NIMS) Certification

- Occupational Safety and Health Administration (OSHA) 10-Hour General Industry Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tin Pourer

- Highlight your experience in operating furnaces and preparing melts.

- Emphasize your knowledge of metal handling and molding techniques.

- Include any experience in quality control or inspection.

- Demonstrate your commitment to safety and compliance.

- Quantify your accomplishments with specific metrics whenever possible.

Essential Experience Highlights for a Strong Tin Pourer Resume

- Operate furnaces to melt tin and other metals

- Prepare melts by adding flux and other chemicals to achieve desired metal properties

- Pour molten metal into molds to create castings

- Maintain molds and crucibles to ensure proper casting quality

- Inspect castings for defects and ensure they meet specifications

- Keep work area clean and organized

- Follow safety protocols and wear appropriate personal protective equipment

Frequently Asked Questions (FAQ’s) For Tin Pourer

What is the primary role of a Tin Pourer?

A Tin Pourer’s primary responsibility is to operate furnaces to melt tin, prepare melts by adding flux and other chemicals, and pour molten metal into molds to create castings.

What are the key skills required for a Tin Pourer?

Key skills for a Tin Pourer include furnace operation, melt preparation, metal handling, molding, casting, and quality inspection.

What industries employ Tin Pourers?

Tin Pourers are employed in various industries, including manufacturing, automotive, and construction.

What is the typical work environment for a Tin Pourer?

Tin Pourers typically work in foundries or manufacturing facilities, where they operate furnaces and casting equipment.

Is a Tin Pourer a dangerous job?

Tin Pouring can involve hazardous materials and high temperatures, so safety protocols and proper protective equipment are essential to minimize risks.

What are the career advancement opportunities for a Tin Pourer?

With experience and additional training, Tin Pourers can advance to supervisory roles or specialize in areas such as melt preparation or casting technology.

What is the average salary for a Tin Pourer?

The average salary for a Tin Pourer can vary depending on experience, location, and industry. According to Glassdoor, the average salary for a Tin Pourer in the United States is around $30,000 per year.