Are you a seasoned Tin Whiz Machine Operator seeking a new career path? Discover our professionally built Tin Whiz Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

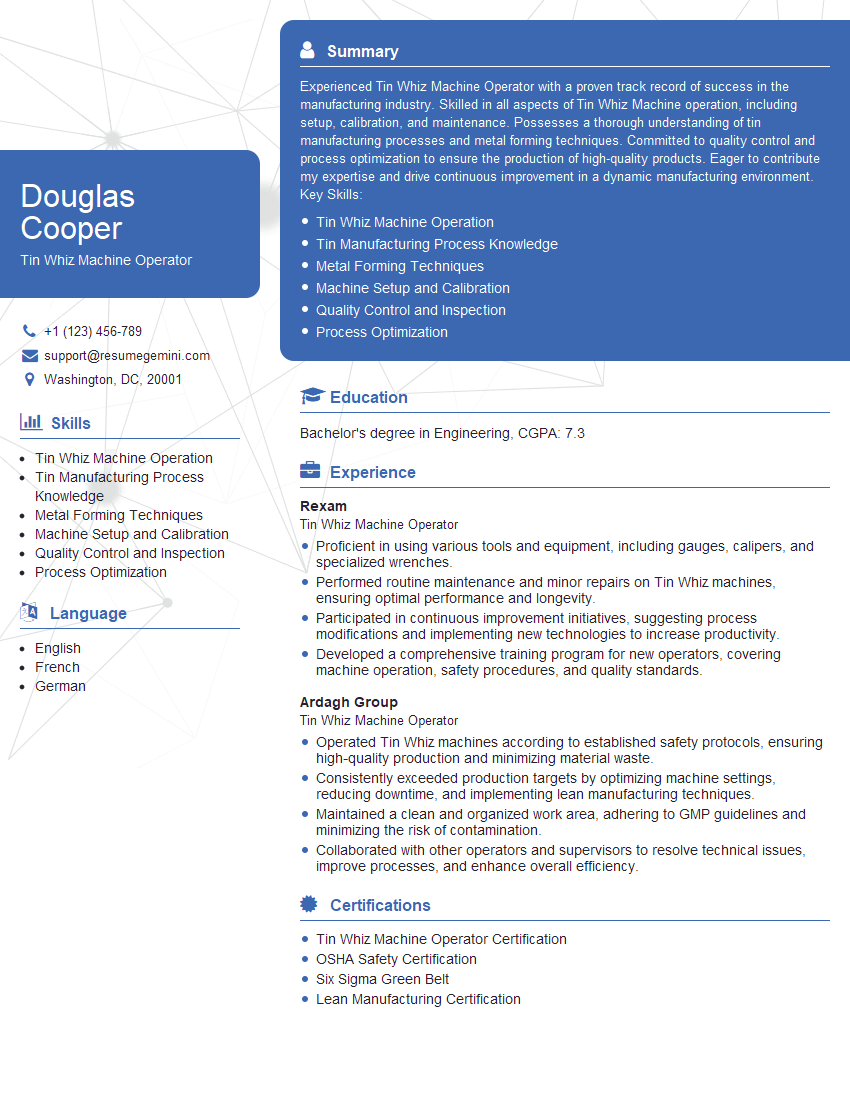

Douglas Cooper

Tin Whiz Machine Operator

Summary

Experienced Tin Whiz Machine Operator with a proven track record of success in the manufacturing industry. Skilled in all aspects of Tin Whiz Machine operation, including setup, calibration, and maintenance. Possesses a thorough understanding of tin manufacturing processes and metal forming techniques. Committed to quality control and process optimization to ensure the production of high-quality products. Eager to contribute my expertise and drive continuous improvement in a dynamic manufacturing environment.

Key Skills:

- Tin Whiz Machine Operation

- Tin Manufacturing Process Knowledge

- Metal Forming Techniques

- Machine Setup and Calibration

- Quality Control and Inspection

- Process Optimization

Education

Bachelor’s degree in Engineering

November 2016

Skills

- Tin Whiz Machine Operation

- Tin Manufacturing Process Knowledge

- Metal Forming Techniques

- Machine Setup and Calibration

- Quality Control and Inspection

- Process Optimization

Work Experience

Tin Whiz Machine Operator

- Proficient in using various tools and equipment, including gauges, calipers, and specialized wrenches.

- Performed routine maintenance and minor repairs on Tin Whiz machines, ensuring optimal performance and longevity.

- Participated in continuous improvement initiatives, suggesting process modifications and implementing new technologies to increase productivity.

- Developed a comprehensive training program for new operators, covering machine operation, safety procedures, and quality standards.

Tin Whiz Machine Operator

- Operated Tin Whiz machines according to established safety protocols, ensuring high-quality production and minimizing material waste.

- Consistently exceeded production targets by optimizing machine settings, reducing downtime, and implementing lean manufacturing techniques.

- Maintained a clean and organized work area, adhering to GMP guidelines and minimizing the risk of contamination.

- Collaborated with other operators and supervisors to resolve technical issues, improve processes, and enhance overall efficiency.

Certificates

- Tin Whiz Machine Operator Certification

- OSHA Safety Certification

- Six Sigma Green Belt

- Lean Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tin Whiz Machine Operator

- Highlight your experience and skills in Tin Whiz Machine operation, including specific examples of your accomplishments.

- Quantify your achievements whenever possible, using metrics to demonstrate the impact of your work.

- Emphasize your understanding of tin manufacturing processes and metal forming techniques.

- Showcase your commitment to quality control and process optimization, providing examples of how you have improved efficiency and reduced waste.

Essential Experience Highlights for a Strong Tin Whiz Machine Operator Resume

- Operate Tin Whiz Machine to manufacture tin containers according to specified dimensions and tolerances.

- Set up and calibrate Tin Whiz Machine to ensure optimal performance and product quality.

- Monitor production processes and conduct quality control inspections to ensure adherence to standards.

- Troubleshoot and resolve machine malfunctions and production issues promptly.

- Perform preventative maintenance and repairs on Tin Whiz Machine to minimize downtime and maintain efficiency.

- Collaborate with team members to optimize production processes and improve overall productivity.

- Comply with safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Tin Whiz Machine Operator

What is a Tin Whiz Machine?

A Tin Whiz Machine is a specialized machine used in the manufacturing of tin containers. It utilizes a series of dies and forming tools to shape and seal tin sheets into the desired shape and size.

What are the key skills required to be a Tin Whiz Machine Operator?

Key skills include proficiency in Tin Whiz Machine operation, knowledge of tin manufacturing processes, metal forming techniques, machine setup and calibration, quality control and inspection, and process optimization.

What are the job responsibilities of a Tin Whiz Machine Operator?

Responsibilities typically include operating the Tin Whiz Machine to manufacture tin containers, setting up and calibrating the machine, monitoring production processes, troubleshooting machine malfunctions, performing maintenance, and adhering to safety regulations.

What industries utilize Tin Whiz Machines?

Tin Whiz Machines are commonly used in the manufacturing of food and beverage containers, paint cans, and other types of tin containers.

What are the career advancement opportunities for a Tin Whiz Machine Operator?

With experience and additional training, Tin Whiz Machine Operators can advance to roles such as Production Supervisor, Quality Control Manager, or Manufacturing Engineer.

What is the average salary for a Tin Whiz Machine Operator?

The average salary for a Tin Whiz Machine Operator can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Tin Whiz Machine Operator in the United States is around $40,000 per year.