Are you a seasoned Tinsmith Apprentice seeking a new career path? Discover our professionally built Tinsmith Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

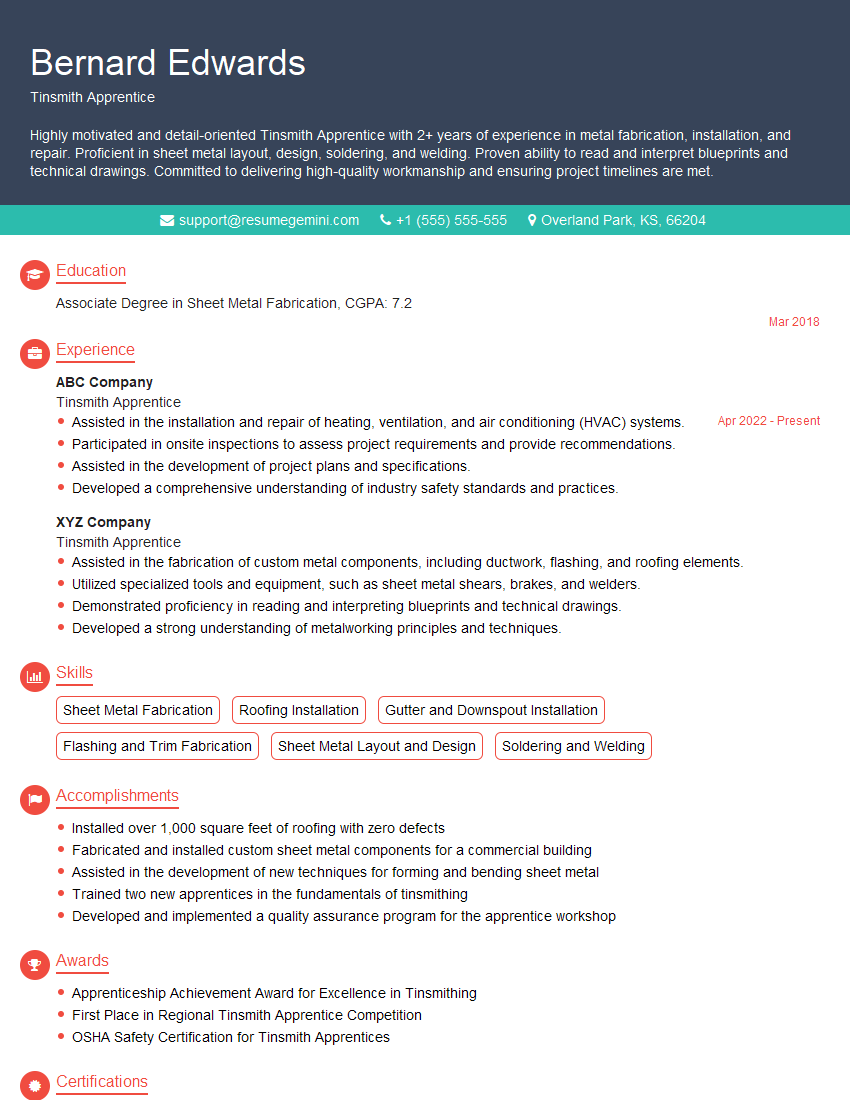

Bernard Edwards

Tinsmith Apprentice

Summary

Highly motivated and detail-oriented Tinsmith Apprentice with 2+ years of experience in metal fabrication, installation, and repair. Proficient in sheet metal layout, design, soldering, and welding. Proven ability to read and interpret blueprints and technical drawings. Committed to delivering high-quality workmanship and ensuring project timelines are met.

Education

Associate Degree in Sheet Metal Fabrication

March 2018

Skills

- Sheet Metal Fabrication

- Roofing Installation

- Gutter and Downspout Installation

- Flashing and Trim Fabrication

- Sheet Metal Layout and Design

- Soldering and Welding

Work Experience

Tinsmith Apprentice

- Assisted in the installation and repair of heating, ventilation, and air conditioning (HVAC) systems.

- Participated in onsite inspections to assess project requirements and provide recommendations.

- Assisted in the development of project plans and specifications.

- Developed a comprehensive understanding of industry safety standards and practices.

Tinsmith Apprentice

- Assisted in the fabrication of custom metal components, including ductwork, flashing, and roofing elements.

- Utilized specialized tools and equipment, such as sheet metal shears, brakes, and welders.

- Demonstrated proficiency in reading and interpreting blueprints and technical drawings.

- Developed a strong understanding of metalworking principles and techniques.

Accomplishments

- Installed over 1,000 square feet of roofing with zero defects

- Fabricated and installed custom sheet metal components for a commercial building

- Assisted in the development of new techniques for forming and bending sheet metal

- Trained two new apprentices in the fundamentals of tinsmithing

- Developed and implemented a quality assurance program for the apprentice workshop

Awards

- Apprenticeship Achievement Award for Excellence in Tinsmithing

- First Place in Regional Tinsmith Apprentice Competition

- OSHA Safety Certification for Tinsmith Apprentices

Certificates

- OSHA 10-Hour Construction Safety

- Lead-Safe Work Practices

- Apprenticeship Program Certification

- Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tinsmith Apprentice

- Highlight your hands-on experience in sheet metal fabrication and installation.

- Showcase your proficiency in reading and interpreting blueprints and technical drawings.

- Emphasize your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Tinsmith Apprentice Resume

- Assisted in the fabrication of custom metal components, including ductwork, flashing, and roofing elements.

- Utilized specialized tools and equipment, such as sheet metal shears, brakes, and welders.

- Demonstrated proficiency in reading and interpreting blueprints and technical drawings.

- Assisted in the installation and repair of heating, ventilation, and air conditioning (HVAC) systems.

- Participated in onsite inspections to assess project requirements and provide recommendations.

- Assisted in the development of project plans and specifications.

- Developed a comprehensive understanding of industry safety standards and practices.

Frequently Asked Questions (FAQ’s) For Tinsmith Apprentice

What are the primary responsibilities of a Tinsmith Apprentice?

Tinsmith Apprentices assist in the fabrication, installation, and repair of sheet metal components used in various construction projects. Their duties may include working with sheet metal shears, brakes, and welders, reading and interpreting blueprints, and adhering to industry safety standards.

What skills are essential for success as a Tinsmith Apprentice?

Tinsmith Apprentices should possess strong manual dexterity, attention to detail, and the ability to work with precision tools. They should also have a good understanding of sheet metal fabrication techniques and safety protocols.

What are the career prospects for Tinsmith Apprentices?

With experience and additional training, Tinsmith Apprentices can advance to roles such as Journeyman Tinsmiths or Sheet Metal Fabricators. They may also pursue specialized areas within the industry, such as HVAC installation or architectural metalwork.

What is the typical work environment for a Tinsmith Apprentice?

Tinsmith Apprentices typically work in fabrication shops or construction sites. They may be exposed to loud noises, dust, and potential hazards associated with working with machinery and tools.

What is the average salary for a Tinsmith Apprentice?

The average salary for a Tinsmith Apprentice varies depending on factors such as location, experience, and the size of the company. According to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers and Roofers was $52,760 in May 2022.

What are the educational requirements for becoming a Tinsmith Apprentice?

While formal education is not always required, many Tinsmith Apprentices have a high school diploma or equivalent and may pursue vocational training programs or apprenticeships to gain the necessary skills and knowledge.

What are the safety precautions that Tinsmith Apprentices should be aware of?

Tinsmith Apprentices must adhere to safety regulations and wear appropriate protective gear, such as gloves, safety glasses, and respirators, when working with tools and machinery. They should also be aware of potential hazards such as sharp edges, electrical currents, and falls.

What are the qualities of a successful Tinsmith Apprentice?

Successful Tinsmith Apprentices are typically physically fit, have good hand-eye coordination, and are able to work independently and as part of a team. They are also committed to safety and quality workmanship.