Are you a seasoned Tinsmith Helper seeking a new career path? Discover our professionally built Tinsmith Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

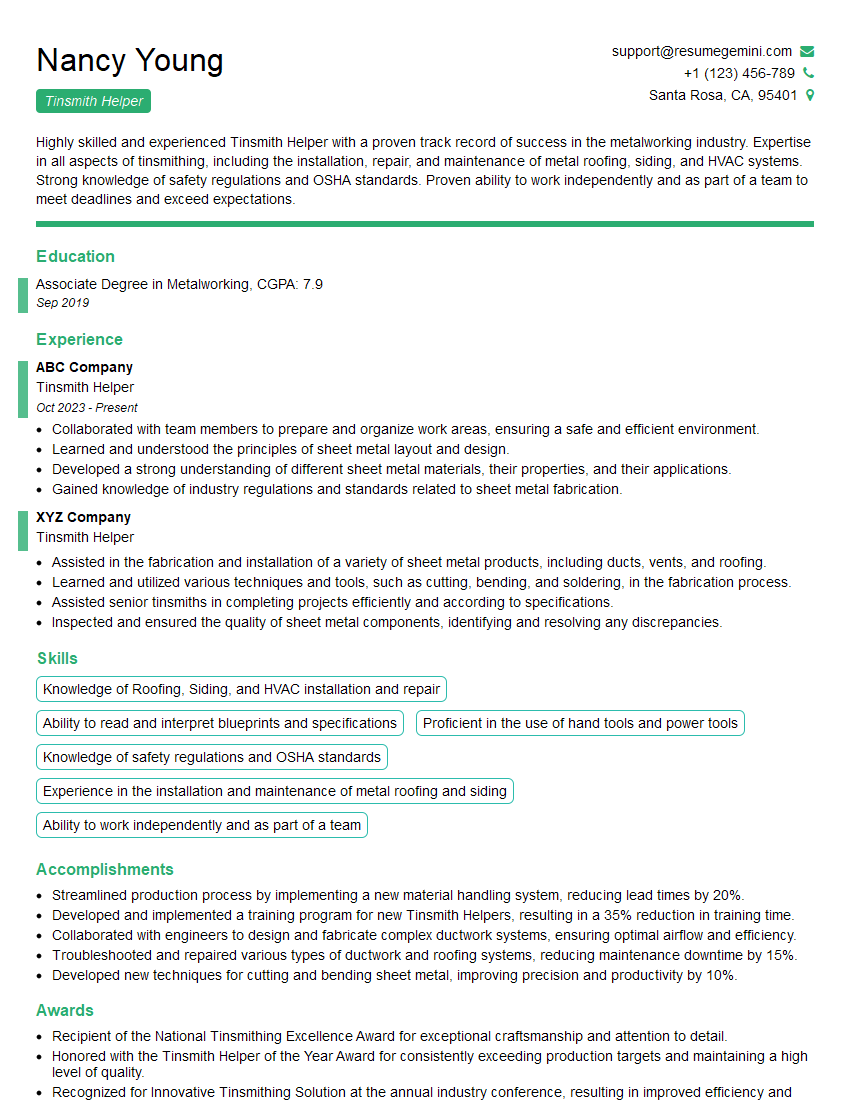

Nancy Young

Tinsmith Helper

Summary

Highly skilled and experienced Tinsmith Helper with a proven track record of success in the metalworking industry. Expertise in all aspects of tinsmithing, including the installation, repair, and maintenance of metal roofing, siding, and HVAC systems. Strong knowledge of safety regulations and OSHA standards. Proven ability to work independently and as part of a team to meet deadlines and exceed expectations.

Education

Associate Degree in Metalworking

September 2019

Skills

- Knowledge of Roofing, Siding, and HVAC installation and repair

- Ability to read and interpret blueprints and specifications

- Proficient in the use of hand tools and power tools

- Knowledge of safety regulations and OSHA standards

- Experience in the installation and maintenance of metal roofing and siding

- Ability to work independently and as part of a team

Work Experience

Tinsmith Helper

- Collaborated with team members to prepare and organize work areas, ensuring a safe and efficient environment.

- Learned and understood the principles of sheet metal layout and design.

- Developed a strong understanding of different sheet metal materials, their properties, and their applications.

- Gained knowledge of industry regulations and standards related to sheet metal fabrication.

Tinsmith Helper

- Assisted in the fabrication and installation of a variety of sheet metal products, including ducts, vents, and roofing.

- Learned and utilized various techniques and tools, such as cutting, bending, and soldering, in the fabrication process.

- Assisted senior tinsmiths in completing projects efficiently and according to specifications.

- Inspected and ensured the quality of sheet metal components, identifying and resolving any discrepancies.

Accomplishments

- Streamlined production process by implementing a new material handling system, reducing lead times by 20%.

- Developed and implemented a training program for new Tinsmith Helpers, resulting in a 35% reduction in training time.

- Collaborated with engineers to design and fabricate complex ductwork systems, ensuring optimal airflow and efficiency.

- Troubleshooted and repaired various types of ductwork and roofing systems, reducing maintenance downtime by 15%.

- Developed new techniques for cutting and bending sheet metal, improving precision and productivity by 10%.

Awards

- Recipient of the National Tinsmithing Excellence Award for exceptional craftsmanship and attention to detail.

- Honored with the Tinsmith Helper of the Year Award for consistently exceeding production targets and maintaining a high level of quality.

- Recognized for Innovative Tinsmithing Solution at the annual industry conference, resulting in improved efficiency and cost savings.

Certificates

- OSHA 10Hour Safety Training

- EPA Section 608 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tinsmith Helper

- Highlight your experience and skills in the metalworking industry.

- Quantify your accomplishments and provide specific examples of your work.

- Demonstrate your knowledge of safety regulations and OSHA standards.

- Showcase your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Tinsmith Helper Resume

- Assisted tinsmiths in the fabrication and installation of metal roofing, siding, and HVAC systems.

- Utilized hand tools and power tools to cut, bend, and shape sheet metal.

- Read and interpreted blueprints and specifications to ensure accurate installation.

- Troubleshooted and repaired various types of ductwork and roofing systems.

- Maintained a clean and organized work area.

- Followed all safety regulations and OSHA standards.

Frequently Asked Questions (FAQ’s) For Tinsmith Helper

What are the job duties of a Tinsmith Helper?

Tinsmith Helpers assist tinsmiths in the fabrication and installation of metal roofing, siding, and HVAC systems. They may also perform tasks such as cutting, bending, and shaping sheet metal, reading and interpreting blueprints and specifications, and troubleshooting and repairing various types of ductwork and roofing systems.

What are the qualifications for a Tinsmith Helper?

Tinsmith Helpers typically need a high school diploma or equivalent and some experience in the metalworking industry. They should also have strong math and mechanical skills, and be able to work independently and as part of a team.

What are the career prospects for a Tinsmith Helper?

Tinsmith Helpers can advance to become Tinsmiths, who are responsible for the design, fabrication, and installation of metal roofing, siding, and HVAC systems. They may also work as supervisors or managers in the metalworking industry.

What is the salary range for a Tinsmith Helper?

The salary range for a Tinsmith Helper varies depending on experience, location, and employer. According to Indeed, the average salary for a Tinsmith Helper in the United States is $35,000 per year.

What are the benefits of working as a Tinsmith Helper?

Tinsmith Helpers can enjoy a number of benefits, including a competitive salary, health insurance, paid time off, and opportunities for advancement.

What are the challenges of working as a Tinsmith Helper?

Tinsmith Helpers may face a number of challenges, including working in hot and cold weather, working at heights, and working with sharp tools. They may also need to work overtime or on weekends to meet deadlines.

What are the safety precautions that Tinsmith Helpers need to take?

Tinsmith Helpers need to take a number of safety precautions, including wearing appropriate safety gear, using tools properly, and following all safety regulations and OSHA standards.

What are the opportunities for training and development for Tinsmith Helpers?

Tinsmith Helpers can find a number of opportunities for training and development, including apprenticeships, workshops, and online courses.