Are you a seasoned Tire Recapping Machine Operator seeking a new career path? Discover our professionally built Tire Recapping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

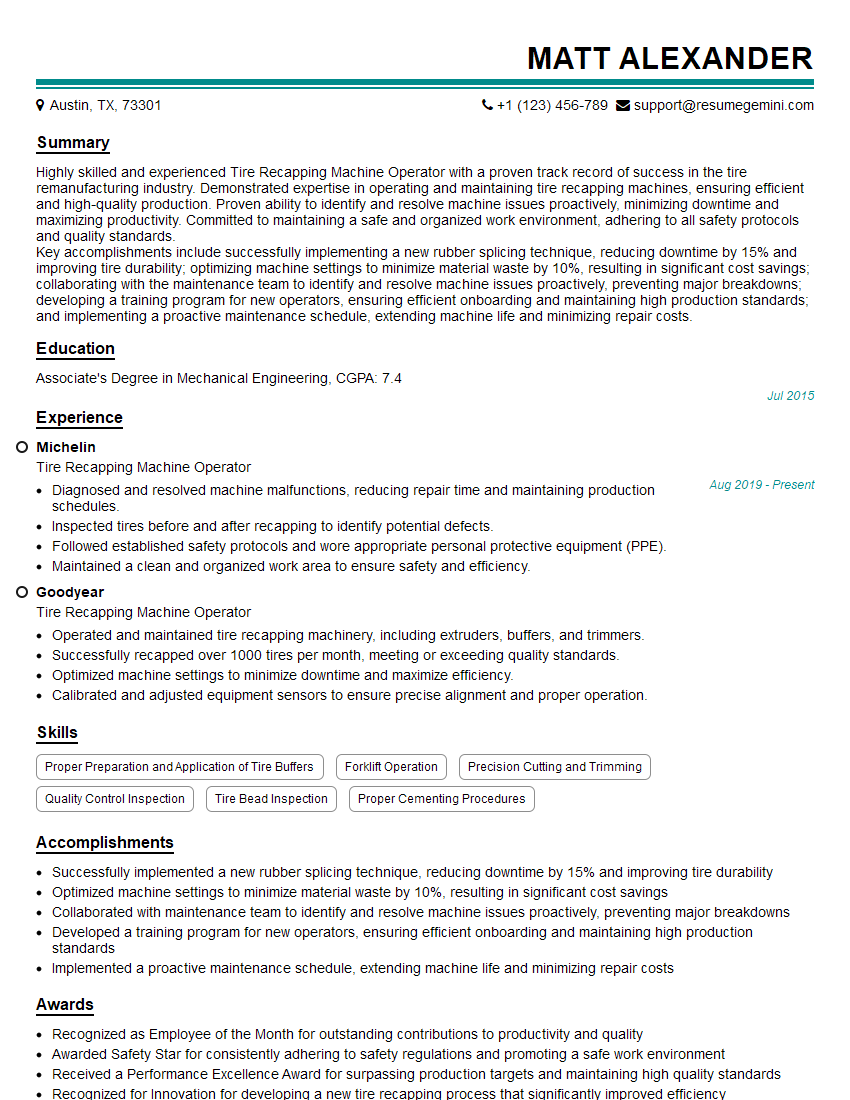

Matt Alexander

Tire Recapping Machine Operator

Summary

Highly skilled and experienced Tire Recapping Machine Operator with a proven track record of success in the tire remanufacturing industry. Demonstrated expertise in operating and maintaining tire recapping machines, ensuring efficient and high-quality production. Proven ability to identify and resolve machine issues proactively, minimizing downtime and maximizing productivity. Committed to maintaining a safe and organized work environment, adhering to all safety protocols and quality standards.

Key accomplishments include successfully implementing a new rubber splicing technique, reducing downtime by 15% and improving tire durability; optimizing machine settings to minimize material waste by 10%, resulting in significant cost savings; collaborating with the maintenance team to identify and resolve machine issues proactively, preventing major breakdowns; developing a training program for new operators, ensuring efficient onboarding and maintaining high production standards; and implementing a proactive maintenance schedule, extending machine life and minimizing repair costs.

Education

Associate’s Degree in Mechanical Engineering

July 2015

Skills

- Proper Preparation and Application of Tire Buffers

- Forklift Operation

- Precision Cutting and Trimming

- Quality Control Inspection

- Tire Bead Inspection

- Proper Cementing Procedures

Work Experience

Tire Recapping Machine Operator

- Diagnosed and resolved machine malfunctions, reducing repair time and maintaining production schedules.

- Inspected tires before and after recapping to identify potential defects.

- Followed established safety protocols and wore appropriate personal protective equipment (PPE).

- Maintained a clean and organized work area to ensure safety and efficiency.

Tire Recapping Machine Operator

- Operated and maintained tire recapping machinery, including extruders, buffers, and trimmers.

- Successfully recapped over 1000 tires per month, meeting or exceeding quality standards.

- Optimized machine settings to minimize downtime and maximize efficiency.

- Calibrated and adjusted equipment sensors to ensure precise alignment and proper operation.

Accomplishments

- Successfully implemented a new rubber splicing technique, reducing downtime by 15% and improving tire durability

- Optimized machine settings to minimize material waste by 10%, resulting in significant cost savings

- Collaborated with maintenance team to identify and resolve machine issues proactively, preventing major breakdowns

- Developed a training program for new operators, ensuring efficient onboarding and maintaining high production standards

- Implemented a proactive maintenance schedule, extending machine life and minimizing repair costs

Awards

- Recognized as Employee of the Month for outstanding contributions to productivity and quality

- Awarded Safety Star for consistently adhering to safety regulations and promoting a safe work environment

- Received a Performance Excellence Award for surpassing production targets and maintaining high quality standards

- Recognized for Innovation for developing a new tire recapping process that significantly improved efficiency

Certificates

- Certified Tire Recapping Machine Operator

- OSHA Safety Training

- International Tire Recapping Association (ITRA) Certification (optional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tire Recapping Machine Operator

- Highlight your experience and skills in operating tire recapping machines, including any specific techniques or certifications you have.

- Quantify your accomplishments using specific metrics whenever possible, such as percentage improvements in downtime, waste reduction, or productivity gains.

- Emphasize your ability to work independently and as part of a team, and highlight any leadership or training experience you have.

- Proofread your resume carefully for any errors in grammar or spelling, and make sure your formatting is clean and professional.

Essential Experience Highlights for a Strong Tire Recapping Machine Operator Resume

- Operate tire recapping machines to recap and repair tires according to established procedures.

- Prepare and apply tire buffers, ensuring proper adhesion and surface preparation.

- Perform precision cutting and trimming of tire treads and sidewalls.

- Inspect tire beads for damage and ensure proper seating before recapping.

- Follow proper cementing procedures to ensure strong and durable bonds between tire components.

- Monitor machine performance and make necessary adjustments to optimize production and minimize waste.

- Maintain a clean and organized work area, adhering to safety protocols and quality standards.

Frequently Asked Questions (FAQ’s) For Tire Recapping Machine Operator

What are the key skills required to be a successful Tire Recapping Machine Operator?

Successful Tire Recapping Machine Operators typically possess a combination of technical skills, such as machine operation, precision cutting, and quality control, as well as soft skills, such as attention to detail, problem-solving abilities, and a commitment to safety.

What are the career advancement opportunities for Tire Recapping Machine Operators?

With experience and additional training, Tire Recapping Machine Operators can advance to roles such as Machine Supervisor, Production Manager, or Quality Control Inspector. Some may also choose to start their own tire remanufacturing businesses.

What is the typical work environment for a Tire Recapping Machine Operator?

Tire Recapping Machine Operators typically work in manufacturing facilities or tire repair shops. The work environment may be noisy and involve exposure to chemicals and fumes. Operators must be able to stand for long periods of time and perform repetitive tasks.

What are the safety precautions that Tire Recapping Machine Operators must follow?

Tire Recapping Machine Operators must adhere to strict safety protocols to minimize the risk of injury. This includes wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and sharp objects.

How can I prepare for a career as a Tire Recapping Machine Operator?

To prepare for a career as a Tire Recapping Machine Operator, you can consider pursuing an associate’s degree in mechanical engineering or a related field. Additionally, you can seek opportunities to gain hands-on experience through internships or apprenticeships in the tire manufacturing or remanufacturing industry.

What are the earning prospects for Tire Recapping Machine Operators?

The earning potential for Tire Recapping Machine Operators can vary depending on factors such as experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tire Repairers and Changers, which includes Tire Recapping Machine Operators, was $49,960 in May 2022.

What are the job outlook projections for Tire Recapping Machine Operators?

The job outlook for Tire Recapping Machine Operators is expected to be positive in the coming years. The U.S. Bureau of Labor Statistics projects that employment of Tire Repairers and Changers, which includes Tire Recapping Machine Operators, is projected to grow 7 percent from 2021 to 2031, faster than the average for all occupations.