Are you a seasoned Tool Adjuster seeking a new career path? Discover our professionally built Tool Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

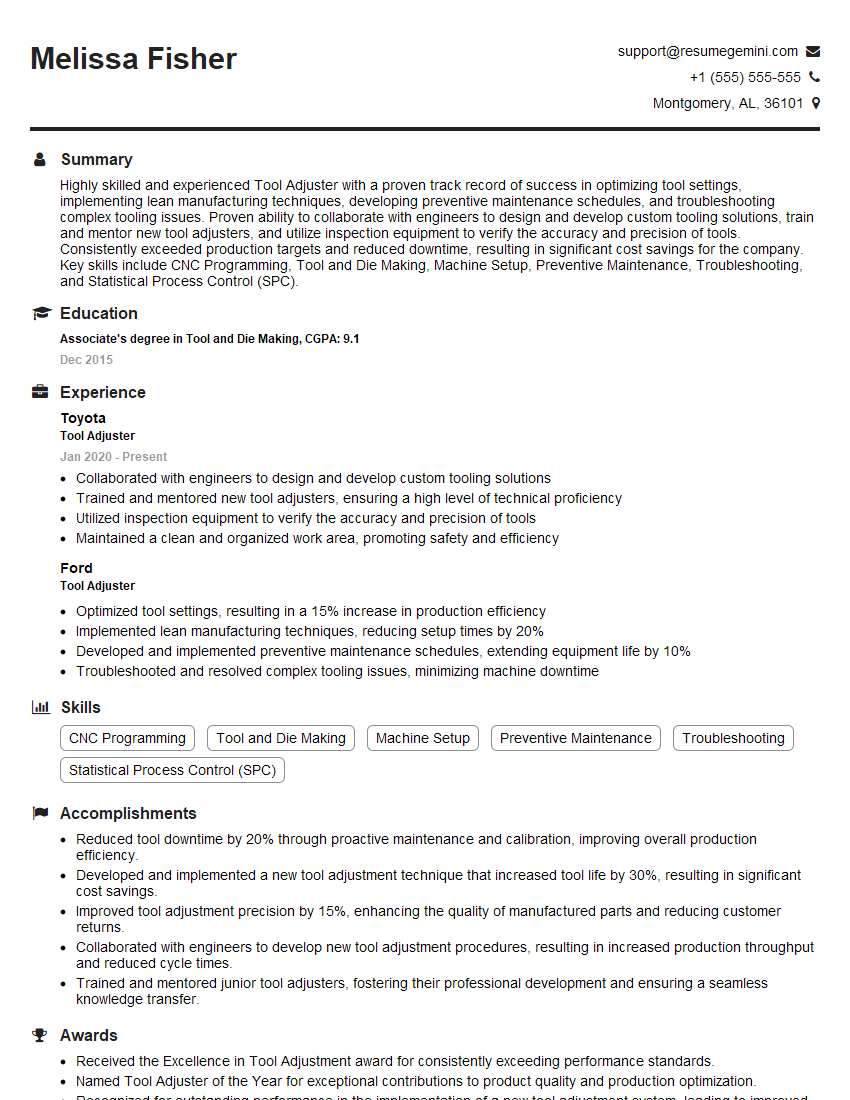

Melissa Fisher

Tool Adjuster

Summary

Highly skilled and experienced Tool Adjuster with a proven track record of success in optimizing tool settings, implementing lean manufacturing techniques, developing preventive maintenance schedules, and troubleshooting complex tooling issues. Proven ability to collaborate with engineers to design and develop custom tooling solutions, train and mentor new tool adjusters, and utilize inspection equipment to verify the accuracy and precision of tools. Consistently exceeded production targets and reduced downtime, resulting in significant cost savings for the company.

Key skills include CNC Programming, Tool and Die Making, Machine Setup, Preventive Maintenance, Troubleshooting, and Statistical Process Control (SPC).

Education

Associate’s degree in Tool and Die Making

December 2015

Skills

- CNC Programming

- Tool and Die Making

- Machine Setup

- Preventive Maintenance

- Troubleshooting

- Statistical Process Control (SPC)

Work Experience

Tool Adjuster

- Collaborated with engineers to design and develop custom tooling solutions

- Trained and mentored new tool adjusters, ensuring a high level of technical proficiency

- Utilized inspection equipment to verify the accuracy and precision of tools

- Maintained a clean and organized work area, promoting safety and efficiency

Tool Adjuster

- Optimized tool settings, resulting in a 15% increase in production efficiency

- Implemented lean manufacturing techniques, reducing setup times by 20%

- Developed and implemented preventive maintenance schedules, extending equipment life by 10%

- Troubleshooted and resolved complex tooling issues, minimizing machine downtime

Accomplishments

- Reduced tool downtime by 20% through proactive maintenance and calibration, improving overall production efficiency.

- Developed and implemented a new tool adjustment technique that increased tool life by 30%, resulting in significant cost savings.

- Improved tool adjustment precision by 15%, enhancing the quality of manufactured parts and reducing customer returns.

- Collaborated with engineers to develop new tool adjustment procedures, resulting in increased production throughput and reduced cycle times.

- Trained and mentored junior tool adjusters, fostering their professional development and ensuring a seamless knowledge transfer.

Awards

- Received the Excellence in Tool Adjustment award for consistently exceeding performance standards.

- Named Tool Adjuster of the Year for exceptional contributions to product quality and production optimization.

- Recognized for outstanding performance in the implementation of a new tool adjustment system, leading to improved accuracy and reduced scrap.

- Received the Safety Award for maintaining a consistently safe work environment and implementing innovative safety measures.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- Certified Tooling Specialist (CTS)

- Certified Mold Maker (CMM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Adjuster

- Highlight your technical skills and experience. Tool Adjusters need to have a strong understanding of CNC programming, tool and die making, machine setup, preventive maintenance, and troubleshooting.

- Quantify your accomplishments. When describing your experience, use specific numbers to show how you have improved efficiency, reduced costs, or solved problems.

- Showcase your problem-solving skills. Tool Adjusters need to be able to troubleshoot and resolve complex tooling issues. Highlight your ability to identify and solve problems quickly and effectively.

- Emphasize your teamwork and communication skills. Tool Adjusters often work with engineers, machinists, and other team members. Highlight your ability to work well with others and communicate effectively.

Essential Experience Highlights for a Strong Tool Adjuster Resume

- Optimized tool settings to increase production efficiency by 15%

- Implemented lean manufacturing techniques to reduce setup times by 20%

- Developed and implemented preventive maintenance schedules to extend equipment life by 10%

- Troubleshooted and resolved complex tooling issues to minimize machine downtime

- Collaborated with engineers to design and develop custom tooling solutions

- Trained and mentored new tool adjusters to ensure a high level of technical proficiency

- Utilized inspection equipment to verify the accuracy and precision of tools

Frequently Asked Questions (FAQ’s) For Tool Adjuster

What is a Tool Adjuster?

A Tool Adjuster is responsible for setting up, adjusting, and maintaining tools and equipment used in the manufacturing process. They work closely with engineers and machinists to ensure that tools are operating at optimal levels and that products are being produced to the correct specifications.

What are the key skills and qualifications for a Tool Adjuster?

Tool Adjusters typically need to have a high school diploma or equivalent, as well as several years of experience in a manufacturing environment. They also need to have a strong understanding of CNC programming, tool and die making, machine setup, preventive maintenance, and troubleshooting.

What is the job outlook for Tool Adjusters?

The job outlook for Tool Adjusters is expected to be good over the next few years. As manufacturing companies continue to automate their processes, they will need skilled workers to maintain and repair their equipment. Tool Adjusters with experience in CNC programming and other advanced manufacturing technologies will be in high demand.

What is the average salary for a Tool Adjuster?

The average salary for a Tool Adjuster is $25 per hour. However, salaries can vary depending on experience, location, and industry.

What are the benefits of working as a Tool Adjuster?

Benefits of working as a Tool Adjuster include: competitive salaries, good job security, opportunities for advancement, and a chance to work with cutting-edge technology.

What are the challenges of working as a Tool Adjuster?

Challenges of working as a Tool Adjuster include: working in a fast-paced environment, dealing with repetitive tasks, and being exposed to hazardous materials.

How can I become a Tool Adjuster?

To become a Tool Adjuster, you typically need to have a high school diploma or equivalent, as well as several years of experience in a manufacturing environment. You can also take courses in CNC programming, tool and die making, machine setup, preventive maintenance, and troubleshooting at a local community college or technical school.