Are you a seasoned Tool and Cutter Grinder seeking a new career path? Discover our professionally built Tool and Cutter Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

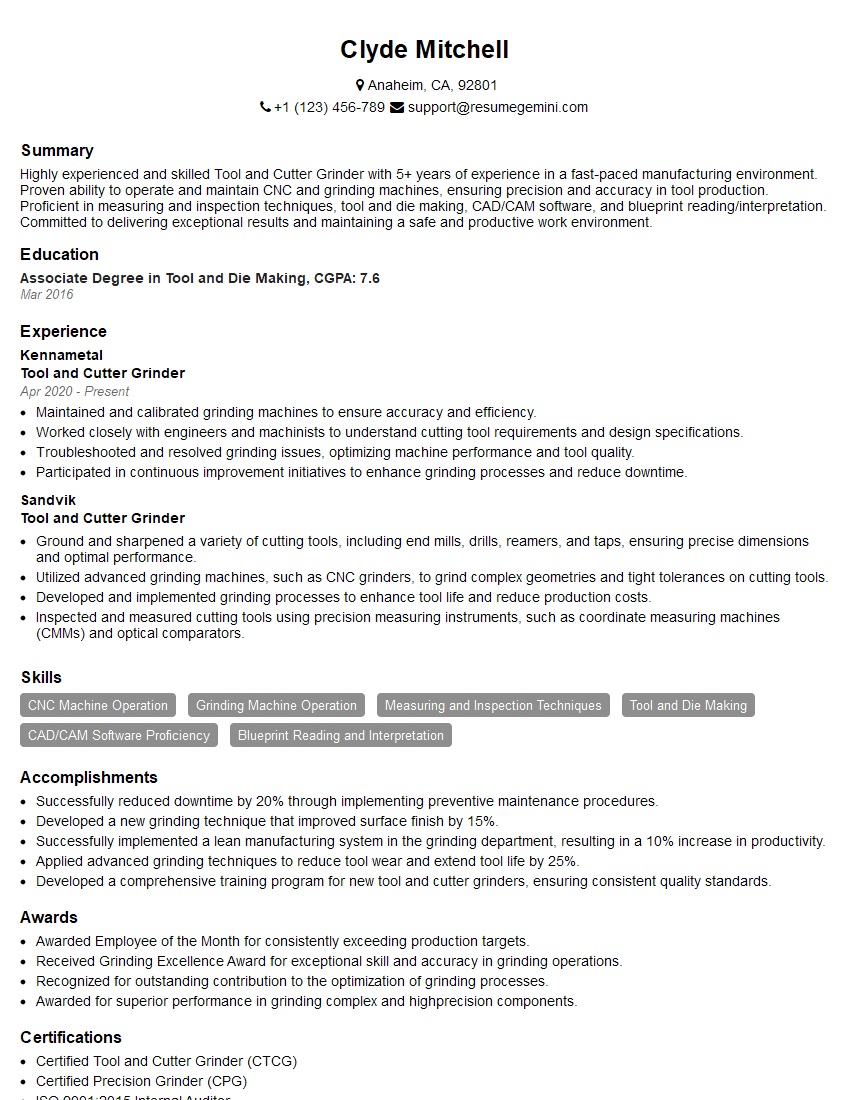

Clyde Mitchell

Tool and Cutter Grinder

Summary

Highly experienced and skilled Tool and Cutter Grinder with 5+ years of experience in a fast-paced manufacturing environment. Proven ability to operate and maintain CNC and grinding machines, ensuring precision and accuracy in tool production. Proficient in measuring and inspection techniques, tool and die making, CAD/CAM software, and blueprint reading/interpretation. Committed to delivering exceptional results and maintaining a safe and productive work environment.

Education

Associate Degree in Tool and Die Making

March 2016

Skills

- CNC Machine Operation

- Grinding Machine Operation

- Measuring and Inspection Techniques

- Tool and Die Making

- CAD/CAM Software Proficiency

- Blueprint Reading and Interpretation

Work Experience

Tool and Cutter Grinder

- Maintained and calibrated grinding machines to ensure accuracy and efficiency.

- Worked closely with engineers and machinists to understand cutting tool requirements and design specifications.

- Troubleshooted and resolved grinding issues, optimizing machine performance and tool quality.

- Participated in continuous improvement initiatives to enhance grinding processes and reduce downtime.

Tool and Cutter Grinder

- Ground and sharpened a variety of cutting tools, including end mills, drills, reamers, and taps, ensuring precise dimensions and optimal performance.

- Utilized advanced grinding machines, such as CNC grinders, to grind complex geometries and tight tolerances on cutting tools.

- Developed and implemented grinding processes to enhance tool life and reduce production costs.

- Inspected and measured cutting tools using precision measuring instruments, such as coordinate measuring machines (CMMs) and optical comparators.

Accomplishments

- Successfully reduced downtime by 20% through implementing preventive maintenance procedures.

- Developed a new grinding technique that improved surface finish by 15%.

- Successfully implemented a lean manufacturing system in the grinding department, resulting in a 10% increase in productivity.

- Applied advanced grinding techniques to reduce tool wear and extend tool life by 25%.

- Developed a comprehensive training program for new tool and cutter grinders, ensuring consistent quality standards.

Awards

- Awarded Employee of the Month for consistently exceeding production targets.

- Received Grinding Excellence Award for exceptional skill and accuracy in grinding operations.

- Recognized for outstanding contribution to the optimization of grinding processes.

- Awarded for superior performance in grinding complex and highprecision components.

Certificates

- Certified Tool and Cutter Grinder (CTCG)

- Certified Precision Grinder (CPG)

- ISO 9001:2015 Internal Auditor

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Cutter Grinder

- Highlight your experience and expertise in operating CNC and grinding machines.

- Demonstrate your proficiency in tool and die making, CAD/CAM software, and blueprint reading.

- Quantify your accomplishments with specific metrics to showcase your impact on tool production.

- Emphasize your commitment to quality and precision, ensuring compliance with industry standards.

Essential Experience Highlights for a Strong Tool and Cutter Grinder Resume

- Set up and operate CNC and grinding machines to produce tools and cutters according to specifications.

- Grind and sharpen tools to precise dimensions using various grinding techniques.

- Inspect and measure tools and cutters using precision instruments to ensure compliance with quality standards.

- Perform tool and die making tasks, including designing, fabricating, and maintaining tools and dies.

- Utilize CAD/CAM software to create and modify tool designs and programs.

- Read and interpret blueprints and technical drawings to determine tool and cutter requirements.

- Maintain a clean and organized work area, ensuring adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Tool and Cutter Grinder

What are the key skills required for a Tool and Cutter Grinder?

Essential skills include CNC and grinding machine operation, tool and die making, CAD/CAM software proficiency, and blueprint reading/interpretation.

What type of training is required to become a Tool and Cutter Grinder?

Typically, an Associate Degree in Tool and Die Making or a related field is required, along with on-the-job training and experience.

What industries employ Tool and Cutter Grinders?

They are primarily employed in manufacturing industries, such as automotive, aerospace, and machinery production.

What is the career outlook for Tool and Cutter Grinders?

The job outlook is expected to be favorable due to the increasing demand for skilled machinists and toolmakers.

What are the safety precautions that must be taken by Tool and Cutter Grinders?

Proper safety gear, including gloves, eye protection, and hearing protection, must be worn to minimize exposure to hazards.

What are the growth opportunities for Tool and Cutter Grinders?

With experience and additional training, advancement opportunities may include becoming a Tool and Die Maker or a CNC Programmer.

What are the challenges faced by Tool and Cutter Grinders?

Challenges include working with hazardous materials, exposure to noise and dust, and the need for continuous training to keep up with technological advancements.

What are the essential qualities of a successful Tool and Cutter Grinder?

Attention to detail, mechanical aptitude, problem-solving abilities, and a commitment to safety are crucial qualities.