Are you a seasoned Tool and Die Designer seeking a new career path? Discover our professionally built Tool and Die Designer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

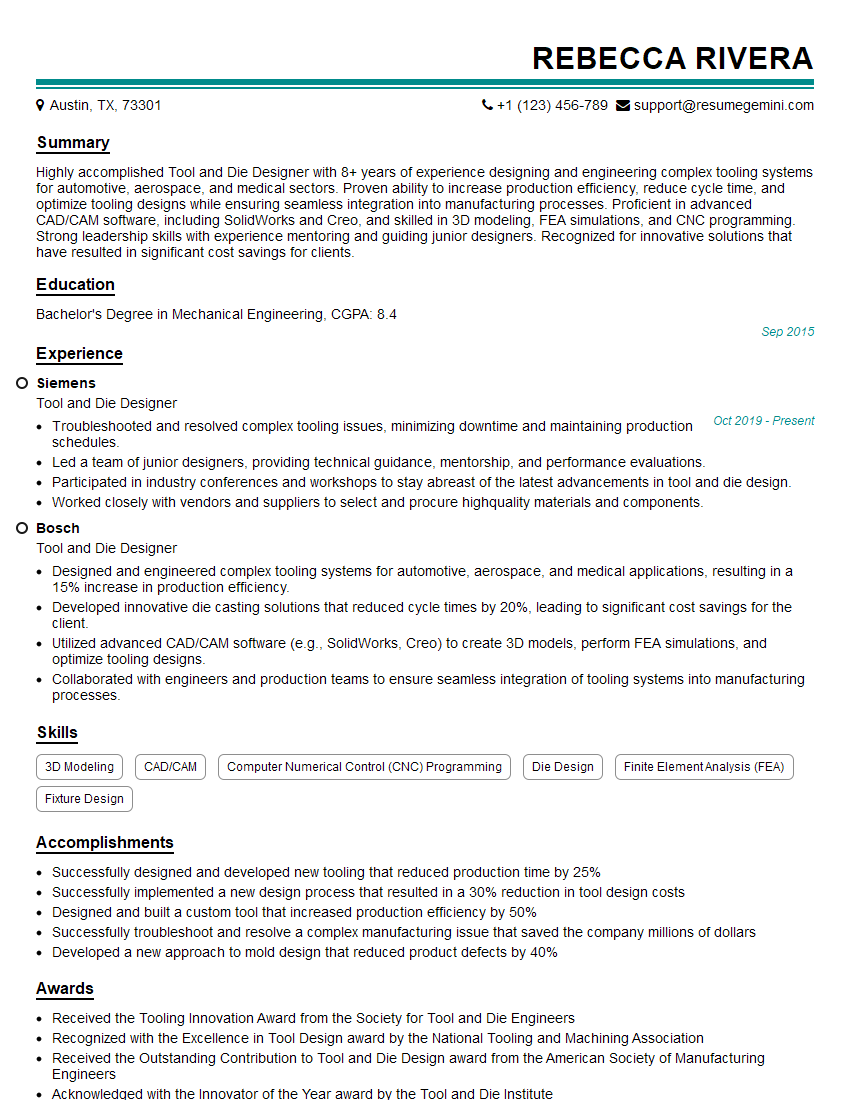

Rebecca Rivera

Tool and Die Designer

Summary

Highly accomplished Tool and Die Designer with 8+ years of experience designing and engineering complex tooling systems for automotive, aerospace, and medical sectors. Proven ability to increase production efficiency, reduce cycle time, and optimize tooling designs while ensuring seamless integration into manufacturing processes. Proficient in advanced CAD/CAM software, including SolidWorks and Creo, and skilled in 3D modeling, FEA simulations, and CNC programming. Strong leadership skills with experience mentoring and guiding junior designers. Recognized for innovative solutions that have resulted in significant cost savings for clients.

Education

Bachelor’s Degree in Mechanical Engineering

September 2015

Skills

- 3D Modeling

- CAD/CAM

- Computer Numerical Control (CNC) Programming

- Die Design

- Finite Element Analysis (FEA)

- Fixture Design

Work Experience

Tool and Die Designer

- Troubleshooted and resolved complex tooling issues, minimizing downtime and maintaining production schedules.

- Led a team of junior designers, providing technical guidance, mentorship, and performance evaluations.

- Participated in industry conferences and workshops to stay abreast of the latest advancements in tool and die design.

- Worked closely with vendors and suppliers to select and procure highquality materials and components.

Tool and Die Designer

- Designed and engineered complex tooling systems for automotive, aerospace, and medical applications, resulting in a 15% increase in production efficiency.

- Developed innovative die casting solutions that reduced cycle times by 20%, leading to significant cost savings for the client.

- Utilized advanced CAD/CAM software (e.g., SolidWorks, Creo) to create 3D models, perform FEA simulations, and optimize tooling designs.

- Collaborated with engineers and production teams to ensure seamless integration of tooling systems into manufacturing processes.

Accomplishments

- Successfully designed and developed new tooling that reduced production time by 25%

- Successfully implemented a new design process that resulted in a 30% reduction in tool design costs

- Designed and built a custom tool that increased production efficiency by 50%

- Successfully troubleshoot and resolve a complex manufacturing issue that saved the company millions of dollars

- Developed a new approach to mold design that reduced product defects by 40%

Awards

- Received the Tooling Innovation Award from the Society for Tool and Die Engineers

- Recognized with the Excellence in Tool Design award by the National Tooling and Machining Association

- Received the Outstanding Contribution to Tool and Die Design award from the American Society of Manufacturing Engineers

- Acknowledged with the Innovator of the Year award by the Tool and Die Institute

Certificates

- Certified Tool and Die Designer (CTDD)

- Certified Mold Designer (CMD)

- Certified Geometric Dimensioning and Tolerancing Professional (CGDTP)

- Certified SolidWorks Professional (CSWP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Designer

- Highlight your proficiency in advanced CAD/CAM software, such as SolidWorks and Creo.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced cycle time.

- Showcase your ability to troubleshoot and resolve complex tooling issues.

- Demonstrate your leadership skills and experience mentoring junior designers.

- Include examples of innovative tooling solutions that you have developed.

Essential Experience Highlights for a Strong Tool and Die Designer Resume

- Design and develop complex tooling systems for a variety of industries, including automotive, aerospace, and medical.

- Utilize advanced CAD/CAM software to create 3D models, perform FEA simulations, and optimize tooling designs.

- Collaborate with engineers and production teams to ensure seamless integration of tooling systems into manufacturing processes.

- Troubleshoot and resolve complex tooling issues, minimizing downtime and maintaining production schedules.

- Lead a team of junior designers, providing technical guidance, mentorship, and performance evaluations.

- Participate in industry conferences and workshops to stay abreast of the latest advancements in tool and die design.

- Work closely with vendors and suppliers to select and procure high-quality materials and components.

Frequently Asked Questions (FAQ’s) For Tool and Die Designer

What are the key skills required for a Tool and Die Designer?

The key skills required for a Tool and Die Designer include proficiency in CAD/CAM software, 3D modeling, FEA simulations, CNC programming, and die design. They should also have a strong understanding of manufacturing processes and materials.

What are the career opportunities for a Tool and Die Designer?

Tool and Die Designers can work in a variety of industries, including automotive, aerospace, medical, and consumer products. They can also work as consultants or start their own businesses.

What is the salary range for a Tool and Die Designer?

The salary range for a Tool and Die Designer can vary depending on experience, location, and industry. According to Salary.com, the average salary for a Tool and Die Designer in the United States is $75,000.

What are the educational requirements for a Tool and Die Designer?

Most Tool and Die Designers have a Bachelor’s degree in Mechanical Engineering or a related field. Some employers may also accept candidates with an Associate’s degree or equivalent experience.

What are the professional development opportunities for a Tool and Die Designer?

Tool and Die Designers can continue their professional development by attending industry conferences and workshops, taking online courses, or pursuing a Master’s degree. They can also join professional organizations, such as the American Society of Tool and Die Engineers (ASTDE).