Are you a seasoned Tool and Die Maker Apprentice seeking a new career path? Discover our professionally built Tool and Die Maker Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

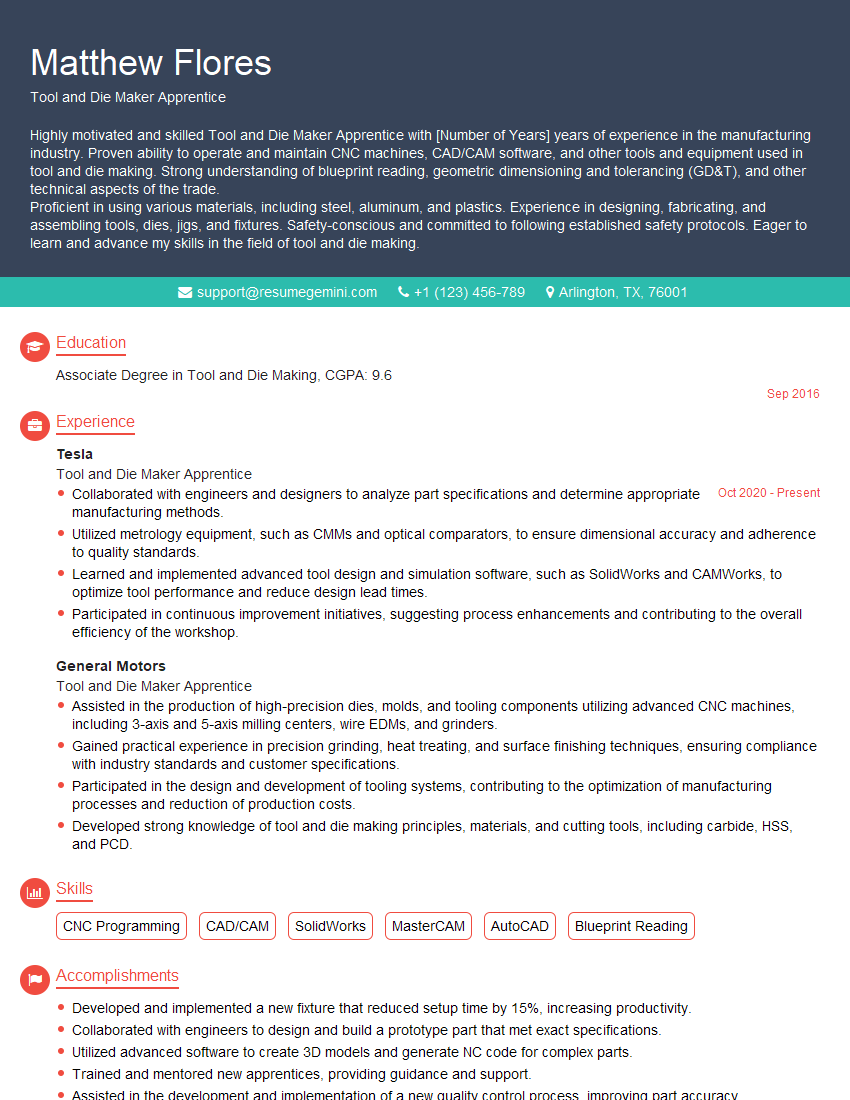

Matthew Flores

Tool and Die Maker Apprentice

Summary

Highly motivated and skilled Tool and Die Maker Apprentice with [Number of Years] years of experience in the manufacturing industry. Proven ability to operate and maintain CNC machines, CAD/CAM software, and other tools and equipment used in tool and die making. Strong understanding of blueprint reading, geometric dimensioning and tolerancing (GD&T), and other technical aspects of the trade.

Proficient in using various materials, including steel, aluminum, and plastics. Experience in designing, fabricating, and assembling tools, dies, jigs, and fixtures. Safety-conscious and committed to following established safety protocols. Eager to learn and advance my skills in the field of tool and die making.

Education

Associate Degree in Tool and Die Making

September 2016

Skills

- CNC Programming

- CAD/CAM

- SolidWorks

- MasterCAM

- AutoCAD

- Blueprint Reading

Work Experience

Tool and Die Maker Apprentice

- Collaborated with engineers and designers to analyze part specifications and determine appropriate manufacturing methods.

- Utilized metrology equipment, such as CMMs and optical comparators, to ensure dimensional accuracy and adherence to quality standards.

- Learned and implemented advanced tool design and simulation software, such as SolidWorks and CAMWorks, to optimize tool performance and reduce design lead times.

- Participated in continuous improvement initiatives, suggesting process enhancements and contributing to the overall efficiency of the workshop.

Tool and Die Maker Apprentice

- Assisted in the production of high-precision dies, molds, and tooling components utilizing advanced CNC machines, including 3-axis and 5-axis milling centers, wire EDMs, and grinders.

- Gained practical experience in precision grinding, heat treating, and surface finishing techniques, ensuring compliance with industry standards and customer specifications.

- Participated in the design and development of tooling systems, contributing to the optimization of manufacturing processes and reduction of production costs.

- Developed strong knowledge of tool and die making principles, materials, and cutting tools, including carbide, HSS, and PCD.

Accomplishments

- Developed and implemented a new fixture that reduced setup time by 15%, increasing productivity.

- Collaborated with engineers to design and build a prototype part that met exact specifications.

- Utilized advanced software to create 3D models and generate NC code for complex parts.

- Trained and mentored new apprentices, providing guidance and support.

- Assisted in the development and implementation of a new quality control process, improving part accuracy.

Awards

- Received the Apprentice of the Year award from the local Tool and Die Makers Association for outstanding performance and dedication.

- Earned the National Skills Competition award for top performance in precision machining.

- Received a scholarship from the Tool and Die Makers Institute for academic excellence.

- Recognized for outstanding performance on the Tool and Die Maker Certification Exam.

Certificates

- Certified Tool and Die Maker

- Certified Manufacturing Technologist

- Lean Six Sigma Green Belt

- ISO 9001:2015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Maker Apprentice

- Highlight your skills and experience: Emphasize your proficiency in CNC programming, CAD/CAM software, and other relevant technical skills.

- Showcase your knowledge: Demonstrate your understanding of blueprint reading, GD&T, and other technical aspects of the trade.

- Quantify your accomplishments: Use numbers and metrics to quantify your achievements and demonstrate the impact of your work.

- Proofread carefully: Ensure that your resume is error-free and well-written, as it will be the first impression you make on potential employers.

Essential Experience Highlights for a Strong Tool and Die Maker Apprentice Resume

- Operate and maintain CNC machines, including milling machines, lathes, and grinders, to create precision parts and components.

- Use CAD/CAM software to design and program tool paths for CNC machines.

- Read and interpret blueprints and other technical drawings to ensure accurate fabrication of tools and dies.

- Inspect and measure parts and components to ensure they meet specifications.

- Assemble and disassemble tools and dies, and perform maintenance and repairs as needed.

- Follow established safety protocols and wear appropriate personal protective equipment (PPE) when operating machinery and handling materials.

- Collaborate with engineers and other team members to develop and improve manufacturing processes.

Frequently Asked Questions (FAQ’s) For Tool and Die Maker Apprentice

What are the main responsibilities of a Tool and Die Maker Apprentice?

Tool and Die Maker Apprentices are responsible for operating and maintaining CNC machines, using CAD/CAM software, reading and interpreting blueprints, inspecting and measuring parts, assembling and disassembling tools and dies, and following established safety protocols.

What are the educational requirements for a Tool and Die Maker Apprentice?

Most Tool and Die Maker Apprentices have an associate degree in Tool and Die Making or a related field.

What are the career prospects for a Tool and Die Maker Apprentice?

Tool and Die Maker Apprentices can advance to become Journeyman Tool and Die Makers, Tooling Engineers, or Manufacturing Supervisors.

What are the key skills for a Tool and Die Maker Apprentice?

Key skills for a Tool and Die Maker Apprentice include CNC programming, CAD/CAM software, blueprint reading, geometric dimensioning and tolerancing (GD&T), and safety consciousness.

What are the typical working conditions for a Tool and Die Maker Apprentice?

Tool and Die Maker Apprentices typically work in a manufacturing environment, operating machinery and handling materials. They may work in a variety of settings, including workshops, factories, and machine shops.

What are the average salary expectations for a Tool and Die Maker Apprentice?

The average salary for a Tool and Die Maker Apprentice varies depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was $56,920 in May 2021.

What are the job outlook prospects for a Tool and Die Maker Apprentice?

The job outlook for Tool and Die Maker Apprentices is expected to be good over the next few years. The U.S. Bureau of Labor Statistics projects that employment of Tool and Die Makers will grow by 6% from 2021 to 2031, faster than the average for all occupations.